What is Global Multihead Weighing Machine Market?

The Global Multihead Weighing Machine Market is a dynamic and essential segment within the broader industrial machinery sector. These machines are designed to weigh products with high precision and speed, making them indispensable in industries where accuracy and efficiency are paramount. Multihead weighing machines consist of multiple weighing heads, typically ranging from 10 to 24, which work in tandem to ensure that the exact amount of product is dispensed. This technology is particularly beneficial in packaging processes, where consistent product weight is crucial for maintaining quality and meeting regulatory standards. The market for these machines is driven by the increasing demand for automation in manufacturing processes, as businesses seek to enhance productivity and reduce labor costs. Additionally, the versatility of multihead weighers, which can handle a wide range of products from granules to fragile items, further boosts their adoption across various sectors. As industries continue to evolve and prioritize efficiency, the global multihead weighing machine market is poised for sustained growth, reflecting its critical role in modern manufacturing and packaging operations.

Screw Feeders, Vibratory Feeders, Others in the Global Multihead Weighing Machine Market:

Screw feeders, vibratory feeders, and other types of feeding systems play a crucial role in the functionality of the global multihead weighing machine market. Each of these feeding mechanisms offers unique advantages and is selected based on the specific requirements of the product being handled. Screw feeders are particularly effective for handling bulk materials that are dry and free-flowing. They operate by using a rotating helical screw blade, known as a flighting, which moves the material through a tube. This method is highly efficient for products like powders and granules, ensuring a consistent and controlled flow into the weighing heads. The precision of screw feeders makes them ideal for applications where maintaining the integrity of the product is essential, such as in the food and pharmaceutical industries. On the other hand, vibratory feeders utilize vibration to move materials along a conveyor path. This type of feeder is especially suitable for fragile or irregularly shaped items, as the gentle vibration minimizes damage during the feeding process. Vibratory feeders are often used in applications where the product needs to be evenly distributed across the weighing heads, ensuring accurate measurements. The versatility of vibratory feeders allows them to handle a wide range of products, from small components to larger items, making them a popular choice in various industries. In addition to screw and vibratory feeders, there are other feeding systems employed in multihead weighing machines, each designed to meet specific operational needs. For instance, belt feeders are used for products that require a smooth and continuous flow, while centrifugal feeders are ideal for high-speed applications where rapid product delivery is necessary. These alternative feeding systems provide flexibility and adaptability, enabling multihead weighers to accommodate diverse product types and production environments. The choice of feeder system is often determined by factors such as product characteristics, production speed, and the level of precision required. As the global multihead weighing machine market continues to expand, the development and integration of advanced feeding technologies will play a pivotal role in enhancing the efficiency and accuracy of these machines. By understanding the unique capabilities of screw feeders, vibratory feeders, and other feeding systems, businesses can optimize their weighing processes, ensuring that they meet the demands of modern manufacturing and packaging operations.

Food Industry, Pharmaceutical Industry, Others in the Global Multihead Weighing Machine Market:

The global multihead weighing machine market finds extensive application across various industries, with the food and pharmaceutical sectors being among the most prominent users. In the food industry, multihead weighers are essential for ensuring that products are packaged with consistent weight and quality. These machines are used to weigh a wide range of food items, from snacks and confectionery to frozen foods and fresh produce. The ability to handle different product types with precision and speed makes multihead weighers invaluable in food processing and packaging. They help manufacturers maintain product integrity, reduce waste, and comply with stringent regulatory standards. In the pharmaceutical industry, the need for accuracy and hygiene is paramount, and multihead weighing machines play a critical role in meeting these requirements. These machines are used to weigh and package pharmaceutical products, ensuring that each package contains the correct dosage. The precision of multihead weighers helps prevent overfilling or underfilling, which can have serious implications for product efficacy and safety. Additionally, the use of stainless steel and other hygienic materials in the construction of these machines ensures that they meet the strict cleanliness standards required in pharmaceutical manufacturing. Beyond the food and pharmaceutical industries, multihead weighing machines are also used in other sectors such as cosmetics, chemicals, and hardware. In the cosmetics industry, for example, these machines are used to weigh and package products like powders and creams, ensuring that each container meets the specified weight. In the chemical industry, multihead weighers are used to handle a variety of materials, from powders to granules, with precision and efficiency. The versatility of these machines allows them to be adapted for different applications, making them a valuable asset in diverse manufacturing environments. As industries continue to evolve and prioritize efficiency and accuracy, the demand for multihead weighing machines is expected to grow, reflecting their critical role in modern production processes.

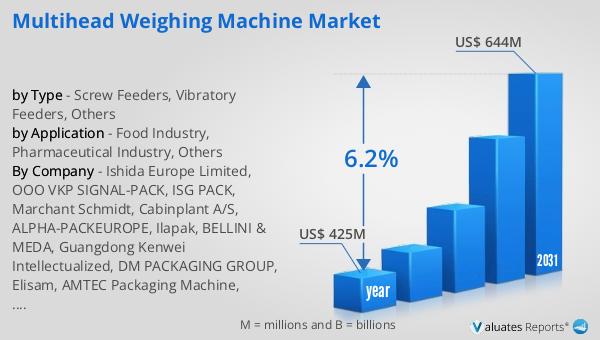

Global Multihead Weighing Machine Market Outlook:

The global market for multihead weighing machines was valued at approximately $425 million in 2024, and it is anticipated to expand to a revised size of around $644 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.2% over the forecast period. This upward trend underscores the increasing demand for precision and efficiency in manufacturing and packaging processes across various industries. The adoption of multihead weighing machines is driven by the need for automation and accuracy, as businesses strive to enhance productivity and reduce operational costs. These machines offer significant advantages in terms of speed and precision, making them indispensable in sectors such as food, pharmaceuticals, and cosmetics. The projected growth in the market reflects the ongoing advancements in technology and the continuous evolution of manufacturing practices. As industries continue to prioritize efficiency and quality, the demand for multihead weighing machines is expected to rise, further solidifying their position as a critical component in modern production environments. The market outlook for multihead weighing machines highlights the importance of these machines in meeting the demands of contemporary manufacturing and packaging operations, ensuring that products are delivered with consistent quality and accuracy.

| Report Metric | Details |

| Report Name | Multihead Weighing Machine Market |

| Accounted market size in year | US$ 425 million |

| Forecasted market size in 2031 | US$ 644 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ishida Europe Limited, OOO VKP SIGNAL-PACK, ISG PACK, Marchant Schmidt, Cabinplant A/S, ALPHA-PACKEUROPE, Ilapak, BELLINI & MEDA, Guangdong Kenwei Intellectualized, DM PACKAGING GROUP, Elisam, AMTEC Packaging Machine, IMANPACK Packaging & Eco Solutions, Talleres Daumar, Sapli, Imbal Stock, Yamato Scale, Martin Engineering, OLI Vibrators, Netter Vibration, Hindon Corporation, Deca Vibrator Industries Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |