What is Global Digital Torsion Testing Machine Market?

The Global Digital Torsion Testing Machine Market refers to the worldwide industry focused on the production, distribution, and utilization of digital torsion testing machines. These machines are specialized equipment used to measure the torque or twisting force applied to an object, which is crucial in assessing the mechanical properties of materials and components. The market encompasses a variety of industries, including automotive, aerospace, construction, and manufacturing, where precise torque measurements are essential for quality control and product development. Digital torsion testing machines offer advanced features such as digital displays, data logging, and automated testing procedures, which enhance accuracy and efficiency. The market is driven by the increasing demand for high-quality materials and components, as well as the need for compliance with stringent industry standards and regulations. As industries continue to innovate and develop new materials and products, the demand for reliable and accurate torsion testing solutions is expected to grow, making the Global Digital Torsion Testing Machine Market a vital component of modern industrial processes.

Uniaxial, Biaxial in the Global Digital Torsion Testing Machine Market:

Uniaxial and biaxial testing are two fundamental methods used in the Global Digital Torsion Testing Machine Market to evaluate the mechanical properties of materials. Uniaxial testing involves applying a single axis of force to a material or component to measure its response to stress or strain. This type of testing is commonly used to determine tensile strength, compressive strength, and elasticity. In the context of digital torsion testing machines, uniaxial testing is essential for assessing the torsional strength and rigidity of materials, which is crucial for applications where components are subjected to twisting forces. The simplicity and precision of uniaxial testing make it a popular choice for quality control and material characterization in various industries. On the other hand, biaxial testing involves applying forces along two axes simultaneously to evaluate the material's behavior under complex loading conditions. This type of testing is particularly important for materials and components that experience multi-directional forces in real-world applications, such as in automotive and aerospace industries. Biaxial testing provides a more comprehensive understanding of a material's mechanical properties, including its ability to withstand combined stresses and strains. In the Global Digital Torsion Testing Machine Market, biaxial testing is used to simulate real-life conditions and ensure that materials and components can perform reliably under various loading scenarios. The choice between uniaxial and biaxial testing depends on the specific requirements of the application and the material being tested. Uniaxial testing is often preferred for its simplicity and ease of implementation, while biaxial testing is chosen for its ability to provide a more complete picture of a material's performance under complex conditions. Both testing methods are integral to the Global Digital Torsion Testing Machine Market, as they enable manufacturers and researchers to develop and validate materials and components that meet the highest standards of quality and performance. In summary, uniaxial and biaxial testing are critical components of the Global Digital Torsion Testing Machine Market, providing valuable insights into the mechanical properties of materials and components. These testing methods help industries ensure that their products can withstand the demands of real-world applications, contributing to the overall reliability and safety of various products and structures. As the market continues to evolve, the importance of accurate and reliable torsion testing solutions will remain a key factor in driving innovation and quality in the manufacturing and research sectors.

Machinery Manufacturing, Research Laboratories, Petrochemical Industry, Others in the Global Digital Torsion Testing Machine Market:

The Global Digital Torsion Testing Machine Market plays a significant role in various industries, including machinery manufacturing, research laboratories, the petrochemical industry, and others. In machinery manufacturing, digital torsion testing machines are used to ensure that components and materials can withstand the mechanical stresses they will encounter during operation. This is crucial for maintaining the safety and reliability of machinery, as well as for optimizing performance and efficiency. By providing precise measurements of torsional strength and rigidity, these machines help manufacturers design and produce high-quality components that meet industry standards and customer expectations. In research laboratories, digital torsion testing machines are essential tools for material characterization and development. Researchers use these machines to study the mechanical properties of new materials and to evaluate their suitability for various applications. The ability to accurately measure torsional properties is critical for advancing material science and engineering, as it enables researchers to develop innovative materials with enhanced performance characteristics. Digital torsion testing machines also facilitate the testing of prototypes and experimental designs, allowing researchers to refine their concepts and bring new products to market more efficiently. The petrochemical industry relies on digital torsion testing machines to ensure the integrity and safety of pipelines, storage tanks, and other critical infrastructure. These machines are used to test the torsional strength of materials used in the construction of petrochemical facilities, ensuring that they can withstand the harsh environmental conditions and mechanical stresses they will encounter. By providing accurate and reliable testing data, digital torsion testing machines help the petrochemical industry maintain compliance with safety regulations and industry standards, reducing the risk of accidents and environmental damage. Beyond these specific industries, digital torsion testing machines are used in a variety of other applications, including construction, aerospace, and automotive sectors. In construction, these machines are used to test the torsional properties of building materials, ensuring that structures can withstand the forces they will encounter during their lifespan. In the aerospace and automotive industries, digital torsion testing machines are used to evaluate the performance of components and materials under the demanding conditions of flight and road travel. By providing accurate and reliable testing data, these machines help manufacturers design and produce safer and more efficient vehicles and aircraft. Overall, the Global Digital Torsion Testing Machine Market is a vital component of modern industrial processes, providing essential tools for ensuring the quality, safety, and performance of materials and components across a wide range of industries. As technology continues to advance and industries seek to develop new and innovative products, the demand for reliable and accurate torsion testing solutions is expected to grow, driving further growth and development in the market.

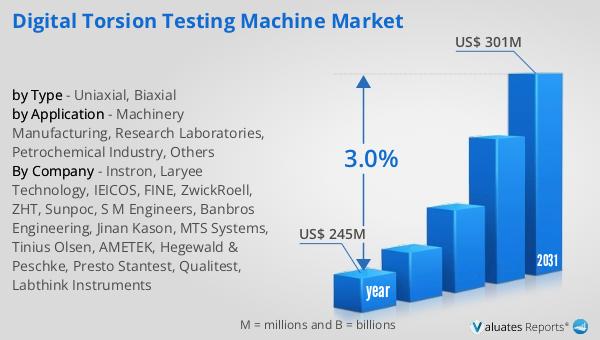

Global Digital Torsion Testing Machine Market Outlook:

In 2024, the global market for Digital Torsion Testing Machines was valued at approximately US$ 245 million. This market is anticipated to expand, reaching an estimated size of US$ 301 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.0% over the forecast period. The steady increase in market size reflects the rising demand for precise and reliable torsion testing solutions across various industries. As industries continue to innovate and develop new materials and products, the need for accurate and efficient testing equipment becomes increasingly critical. The projected growth in the market underscores the importance of digital torsion testing machines in ensuring the quality and performance of materials and components. This expansion is driven by the ongoing advancements in technology and the increasing emphasis on quality control and compliance with industry standards. As a result, the Global Digital Torsion Testing Machine Market is poised to play a crucial role in supporting the development and production of high-quality products across a wide range of sectors.

| Report Metric | Details |

| Report Name | Digital Torsion Testing Machine Market |

| Accounted market size in year | US$ 245 million |

| Forecasted market size in 2031 | US$ 301 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Instron, Laryee Technology, IEICOS, FINE, ZwickRoell, ZHT, Sunpoc, S M Engineers, Banbros Engineering, Jinan Kason, MTS Systems, Tinius Olsen, AMETEK, Hegewald & Peschke, Presto Stantest, Qualitest, Labthink Instruments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |