What is Global Performance Economy Planetary Gearboxes Market?

The Global Performance Economy Planetary Gearboxes Market is a specialized segment within the broader mechanical components industry, focusing on gear systems that are integral to various machinery and equipment. Planetary gearboxes are renowned for their efficiency and compact design, which allow them to deliver high torque in a small package. These gearboxes are used in applications where space is limited but high power transmission is required. The market for these gearboxes is driven by their versatility and ability to enhance the performance of machines across different sectors. With advancements in technology, these gearboxes have become more efficient, reliable, and cost-effective, making them a preferred choice for industries looking to optimize their operations. The global market is characterized by a mix of established players and new entrants, all striving to innovate and capture a larger share of the market. As industries continue to evolve and demand more efficient machinery, the Global Performance Economy Planetary Gearboxes Market is expected to grow, driven by the need for high-performance, durable, and compact gear solutions.

In Line Planetary Gearboxes, Right-Angle Planetary Gearboxes in the Global Performance Economy Planetary Gearboxes Market:

In Line Planetary Gearboxes and Right-Angle Planetary Gearboxes are two primary types of gear systems that play a crucial role in the Global Performance Economy Planetary Gearboxes Market. In Line Planetary Gearboxes are designed to provide a direct and efficient transfer of power. They are characterized by their coaxial input and output shafts, which means that the input and output are aligned in a straight line. This design is particularly beneficial in applications where space is limited, and a compact solution is required. In Line Planetary Gearboxes are known for their high efficiency, low backlash, and ability to handle high torque loads, making them ideal for precision applications such as robotics and machine tools. On the other hand, Right-Angle Planetary Gearboxes are designed to change the direction of the power flow by 90 degrees. This is achieved through the use of bevel gears, which allow the gearbox to transmit power at a right angle. Right-Angle Planetary Gearboxes are often used in applications where space constraints require a change in the direction of power transmission. They are commonly found in industries such as aerospace, medical devices, and packaging machinery, where the layout of the equipment necessitates a right-angle configuration. Both types of gearboxes offer unique advantages and are chosen based on the specific requirements of the application. In Line Planetary Gearboxes are preferred for their simplicity and efficiency, while Right-Angle Planetary Gearboxes are favored for their ability to fit into complex machinery layouts. The choice between the two often depends on factors such as space availability, torque requirements, and the desired orientation of the output shaft. As the Global Performance Economy Planetary Gearboxes Market continues to grow, manufacturers are focusing on developing innovative solutions that combine the benefits of both In Line and Right-Angle configurations. This includes the development of hybrid gearboxes that offer the compactness of In Line designs with the directional flexibility of Right-Angle systems. Such innovations are expected to drive the market forward, providing industries with more versatile and efficient gear solutions.

Robotics, Food Processing Machinery, Packaging Machinery, Textile, Printing Machinery, Semiconductor Equipment, Machine Tools, Aerospace, Medical Devices, Engineering Machinery, Others in the Global Performance Economy Planetary Gearboxes Market:

The Global Performance Economy Planetary Gearboxes Market finds extensive usage across a wide range of industries, each benefiting from the unique advantages offered by these gear systems. In the field of robotics, planetary gearboxes are essential for providing the precision and control required for robotic arms and automated systems. Their ability to deliver high torque in a compact form factor makes them ideal for applications where space is limited, and precise movements are crucial. In the food processing machinery sector, planetary gearboxes are used to drive mixers, conveyors, and other equipment, ensuring efficient and reliable operation. Their robust design and ability to handle high loads make them suitable for the demanding conditions of food processing environments. Packaging machinery also relies heavily on planetary gearboxes for tasks such as labeling, filling, and sealing. The high efficiency and low maintenance requirements of these gearboxes contribute to the smooth and continuous operation of packaging lines. In the textile industry, planetary gearboxes are used in looms and other machinery to ensure precise control over the weaving process. Their ability to handle high speeds and loads makes them indispensable for textile manufacturing. Printing machinery benefits from the use of planetary gearboxes by achieving accurate and consistent print quality. The gearboxes provide the necessary torque and speed control to ensure that printing operations run smoothly and efficiently. In the semiconductor equipment industry, planetary gearboxes are used in wafer handling and processing equipment, where precision and reliability are paramount. Their compact design and high performance make them ideal for the intricate processes involved in semiconductor manufacturing. Machine tools, such as lathes and milling machines, utilize planetary gearboxes to achieve the precision and power required for metalworking operations. The aerospace industry relies on planetary gearboxes for applications such as landing gear systems and flight control mechanisms, where reliability and performance are critical. In the medical devices sector, planetary gearboxes are used in equipment such as surgical robots and imaging systems, where precision and control are essential. Engineering machinery, including construction and mining equipment, benefits from the high torque and durability of planetary gearboxes, which are used to drive various components and systems. Other industries, such as renewable energy and automotive, also utilize planetary gearboxes for their efficiency and performance advantages. As the Global Performance Economy Planetary Gearboxes Market continues to expand, these gear systems are expected to play an increasingly important role in enhancing the performance and efficiency of machinery across diverse sectors.

Global Performance Economy Planetary Gearboxes Market Outlook:

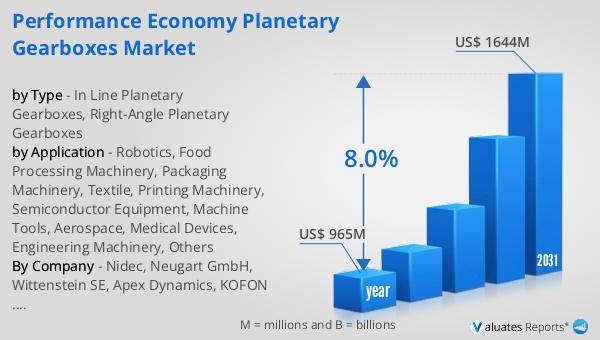

The outlook for the Global Performance Economy Planetary Gearboxes Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 965 million, reflecting the strong demand for efficient and compact gear solutions across various industries. By 2031, the market is projected to reach a revised size of US$ 1644 million, driven by a compound annual growth rate (CAGR) of 8.0% during the forecast period. This growth is indicative of the increasing adoption of planetary gearboxes in sectors such as robotics, aerospace, and medical devices, where precision and performance are paramount. The market's expansion is also fueled by technological advancements that have enhanced the efficiency and reliability of these gear systems. As industries continue to seek ways to optimize their operations and improve the performance of their machinery, the demand for high-quality planetary gearboxes is expected to rise. The market's growth trajectory underscores the importance of innovation and the development of new solutions that meet the evolving needs of various sectors. With a focus on delivering high-performance, durable, and cost-effective gear solutions, the Global Performance Economy Planetary Gearboxes Market is poised for continued success in the years to come.

| Report Metric | Details |

| Report Name | Performance Economy Planetary Gearboxes Market |

| Accounted market size in year | US$ 965 million |

| Forecasted market size in 2031 | US$ 1644 million |

| CAGR | 8.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nidec, Neugart GmbH, Wittenstein SE, Apex Dynamics, KOFON Motion Group, LI-MING Machinery, Newstart, Rouist, STOBER, Harmonic Drive Systems, Ningbo ZhongDa Leader, ZF, Sesame Motor, Sumitomo, PIN HONG TECHNOLOGY, Shanghai Lian Heng Precision Machinery, Shenzhen Zhikong Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |