What is Global Automated Micro Bioreactor System Market?

The Global Automated Micro Bioreactor System Market is a rapidly evolving sector that focuses on the development and deployment of advanced bioreactor systems designed to automate and streamline the process of cultivating microorganisms and cells. These systems are crucial in various fields, including pharmaceuticals, biotechnology, and industrial chemistry, as they allow for precise control over environmental conditions such as temperature, pH, and oxygen levels. This precision is essential for optimizing the growth and productivity of biological cultures. Automated micro bioreactor systems are typically small-scale, high-throughput devices that enable researchers to conduct multiple experiments simultaneously, thereby accelerating the research and development process. They are equipped with sophisticated software and sensors that provide real-time data and analytics, facilitating better decision-making and process optimization. As industries increasingly seek to enhance efficiency and reduce costs, the demand for these automated systems is expected to grow, making them a vital component of modern bioprocessing and research initiatives. The market is characterized by continuous innovation, with companies investing heavily in research and development to introduce more advanced and user-friendly systems. This trend is likely to continue as the need for efficient and scalable bioprocessing solutions becomes more pronounced across various sectors.

24-Parallel Bioreactor System, 48-Parallel Bioreactor System in the Global Automated Micro Bioreactor System Market:

The 24-Parallel Bioreactor System and 48-Parallel Bioreactor System are integral components of the Global Automated Micro Bioreactor System Market, each offering unique advantages for high-throughput experimentation and process optimization. The 24-Parallel Bioreactor System is designed to facilitate simultaneous cultivation of 24 individual cultures, making it ideal for medium-scale research and development projects. This system is particularly beneficial for applications that require a moderate level of throughput, allowing researchers to conduct multiple experiments in parallel without compromising on the quality or accuracy of the results. The system is equipped with advanced control features that enable precise regulation of environmental parameters, ensuring optimal growth conditions for each culture. This level of control is crucial for experiments that require fine-tuning of variables to achieve desired outcomes. On the other hand, the 48-Parallel Bioreactor System offers an even higher level of throughput, accommodating 48 individual cultures simultaneously. This system is particularly suited for large-scale research projects and industrial applications where high-volume experimentation is necessary. The increased capacity of the 48-Parallel System allows for more extensive data collection and analysis, providing researchers with a comprehensive understanding of the biological processes under investigation. Both systems are equipped with state-of-the-art software that facilitates real-time monitoring and data acquisition, enabling researchers to make informed decisions based on accurate and up-to-date information. The software is designed to be user-friendly, allowing researchers to easily set up and manage experiments without requiring extensive technical expertise. Additionally, both systems are compatible with a wide range of biological cultures, making them versatile tools for various research and industrial applications. The ability to conduct high-throughput experiments with these systems significantly reduces the time and resources required for research and development, leading to faster innovation and product development. As the demand for efficient and scalable bioprocessing solutions continues to grow, the 24-Parallel and 48-Parallel Bioreactor Systems are expected to play a crucial role in meeting the needs of researchers and industries worldwide. Their ability to provide precise control over experimental conditions, coupled with their high-throughput capabilities, makes them indispensable tools for advancing scientific research and industrial bioprocessing.

Pharmaceutical, Biotechnology, Industrial Chemistry, Others in the Global Automated Micro Bioreactor System Market:

The Global Automated Micro Bioreactor System Market finds extensive application across various sectors, including pharmaceuticals, biotechnology, industrial chemistry, and others, each benefiting from the unique capabilities of these advanced systems. In the pharmaceutical industry, automated micro bioreactor systems are used to streamline the drug development process by enabling high-throughput screening of potential drug candidates. These systems allow researchers to conduct multiple experiments simultaneously, significantly reducing the time and cost associated with drug discovery and development. The precise control over environmental conditions provided by these systems ensures optimal growth and productivity of cell cultures, leading to more reliable and reproducible results. In biotechnology, automated micro bioreactor systems are employed for the development and optimization of bioprocesses, such as the production of biofuels, enzymes, and other bioproducts. The ability to conduct parallel experiments allows researchers to quickly identify the most efficient and cost-effective production methods, accelerating the commercialization of biotechnological innovations. In industrial chemistry, these systems are used to optimize chemical reactions and processes, improving yield and efficiency while reducing waste and environmental impact. The real-time monitoring and data acquisition capabilities of automated micro bioreactor systems enable chemists to fine-tune reaction conditions and achieve desired outcomes with greater precision. Beyond these sectors, automated micro bioreactor systems are also used in academic and research institutions for a wide range of applications, from basic research to applied science. Their versatility and scalability make them valuable tools for advancing scientific knowledge and driving innovation across various fields. As industries continue to seek more efficient and sustainable solutions, the demand for automated micro bioreactor systems is expected to grow, further expanding their application and impact.

Global Automated Micro Bioreactor System Market Outlook:

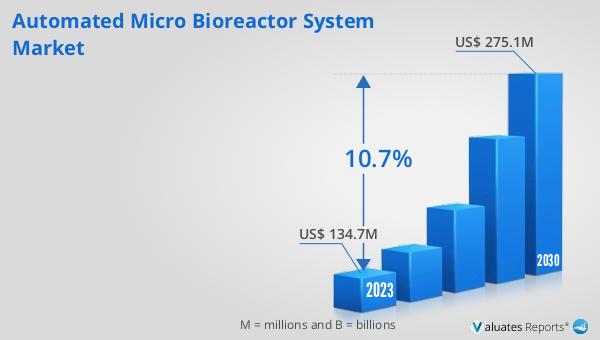

The outlook for the Global Automated Micro Bioreactor System Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 164 million, reflecting the increasing demand for advanced bioprocessing solutions across various industries. By 2031, the market is projected to reach a revised size of US$ 331 million, driven by a compound annual growth rate (CAGR) of 10.7% during the forecast period. This growth is indicative of the rising adoption of automated micro bioreactor systems as industries seek to enhance efficiency, reduce costs, and accelerate research and development processes. The market's expansion is supported by continuous innovation and technological advancements, with companies investing heavily in research and development to introduce more sophisticated and user-friendly systems. As the need for scalable and efficient bioprocessing solutions becomes more pronounced, the Global Automated Micro Bioreactor System Market is poised to play a crucial role in meeting the evolving needs of researchers and industries worldwide. The projected growth underscores the importance of these systems in driving scientific and industrial advancements, making them indispensable tools for modern bioprocessing and research initiatives.

| Report Metric | Details |

| Report Name | Automated Micro Bioreactor System Market |

| Accounted market size in year | US$ 164 million |

| Forecasted market size in 2031 | US$ 331 million |

| CAGR | 10.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sartorius, HiTec Zang, Sysbiotech, Applikon Biotechnology, Eppendorf, Chemtrix CerCell, RUAG Space Nyon, Merck Millipore, Pall, PreSens Precision Sensing, PARR, M2p-labs, INFORS HT, Mani Dharma Biotech, PBS Biotech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |