What is Global Alumina Ceramic Heating Elements Market?

The Global Alumina Ceramic Heating Elements Market is a specialized segment within the broader heating elements industry, focusing on the use of alumina ceramics as a primary material. Alumina ceramics are known for their excellent thermal conductivity, high-temperature stability, and electrical insulation properties, making them ideal for heating applications. These elements are used in various industries due to their ability to withstand extreme temperatures and corrosive environments. The market is driven by the increasing demand for energy-efficient and durable heating solutions across different sectors, including automotive, industrial, and household applications. The growth of this market is also fueled by advancements in technology that enhance the performance and efficiency of alumina ceramic heating elements. As industries continue to seek reliable and long-lasting heating solutions, the demand for alumina ceramic heating elements is expected to rise, contributing to the market's expansion. The market's growth is further supported by the rising awareness of the benefits of using ceramic materials in heating applications, such as reduced energy consumption and lower maintenance costs. Overall, the Global Alumina Ceramic Heating Elements Market is poised for significant growth as industries continue to prioritize efficiency and sustainability in their operations.

Rod Type, Plate Type, Tube Type, Others in the Global Alumina Ceramic Heating Elements Market:

In the Global Alumina Ceramic Heating Elements Market, various types of heating elements are utilized, each serving specific applications and offering unique benefits. The Rod Type heating elements are cylindrical and are commonly used in applications requiring direct contact heating. These elements are favored for their uniform heat distribution and ability to reach high temperatures quickly. They are often employed in industrial settings where precise temperature control is essential. The Plate Type heating elements, on the other hand, are flat and are typically used in applications where surface heating is required. These elements are ideal for heating large areas evenly and are often used in household appliances such as ovens and cooktops. Their flat design allows for efficient heat transfer and quick response times, making them suitable for applications where rapid heating is necessary. Tube Type heating elements are hollow and are used in applications where indirect heating is preferred. These elements are commonly found in industrial processes where fluids or gases need to be heated. Their tubular design allows for efficient heat exchange and minimizes heat loss, making them an energy-efficient option for various heating applications. Lastly, the category of Others includes specialized heating elements that do not fit into the standard rod, plate, or tube categories. These elements are often custom-designed to meet specific requirements and are used in niche applications where standard heating elements may not be suitable. The diversity of heating element types in the Global Alumina Ceramic Heating Elements Market allows for a wide range of applications, catering to the specific needs of different industries. Each type of heating element offers distinct advantages, making them suitable for various applications and contributing to the overall growth of the market. As industries continue to evolve and demand more efficient and reliable heating solutions, the market for alumina ceramic heating elements is expected to expand, driven by the versatility and performance of these advanced materials.

Automotive Components, Household Heating Components, Industrial Heating Components, Others in the Global Alumina Ceramic Heating Elements Market:

The Global Alumina Ceramic Heating Elements Market finds extensive usage across various sectors, including automotive components, household heating components, industrial heating components, and others. In the automotive industry, alumina ceramic heating elements are used in components such as engine heaters, seat heaters, and battery heaters. These elements provide efficient and reliable heating solutions that enhance the performance and comfort of vehicles. Their ability to withstand high temperatures and corrosive environments makes them ideal for automotive applications, where durability and efficiency are paramount. In household heating components, alumina ceramic heating elements are used in appliances such as ovens, toasters, and space heaters. Their excellent thermal conductivity and rapid heating capabilities make them suitable for household applications where quick and efficient heating is required. These elements contribute to energy savings and improved performance of household appliances, making them a popular choice among consumers. In industrial heating components, alumina ceramic heating elements are used in processes such as drying, curing, and heat treatment. Their ability to provide consistent and uniform heat distribution is crucial in industrial applications where precise temperature control is necessary. These elements are also used in the manufacturing of semiconductors and other electronic components, where their high-temperature stability and electrical insulation properties are essential. The category of Others includes specialized applications such as medical devices, laboratory equipment, and scientific instruments, where alumina ceramic heating elements are used for their reliability and performance. The versatility and efficiency of alumina ceramic heating elements make them suitable for a wide range of applications, contributing to their growing demand across various sectors. As industries continue to seek advanced heating solutions that offer energy efficiency and durability, the Global Alumina Ceramic Heating Elements Market is expected to witness significant growth.

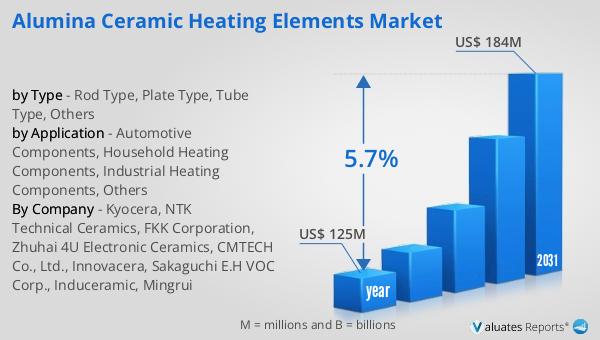

Global Alumina Ceramic Heating Elements Market Outlook:

The global market for Alumina Ceramic Heating Elements was valued at $125 million in 2024 and is anticipated to grow to a revised size of $184 million by 2031, with a compound annual growth rate (CAGR) of 5.7% during the forecast period. In 2022, the top three companies dominated the market, accounting for over 68% of the global revenue share. Kyocera leads the market with a 49.27% revenue share, followed by NTK Technical Ceramics and FKK Corporation, which hold 11.91% and 6.87% of the global revenue share, respectively. In terms of sales volume, North America accounted for 11.66% of the global sales in 2022, while Europe contributed 15.45%. China emerged as a significant player, representing 31.23% of the sales volume, followed by Japan at 10.38%, Southeast Asia at 10.95%, and India at 7.56%. Other regions collectively accounted for 12.78% of the sales volume. This data highlights the geographical distribution and market dominance of key players in the Global Alumina Ceramic Heating Elements Market, reflecting the growing demand and adoption of these advanced heating solutions across different regions. The market's expansion is driven by the increasing need for efficient and reliable heating elements in various industries, supported by technological advancements and the rising awareness of the benefits of using alumina ceramics in heating applications.

| Report Metric | Details |

| Report Name | Alumina Ceramic Heating Elements Market |

| Accounted market size in year | US$ 125 million |

| Forecasted market size in 2031 | US$ 184 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kyocera, NTK Technical Ceramics, FKK Corporation, Zhuhai 4U Electronic Ceramics, CMTECH Co., Ltd., Innovacera, Sakaguchi E.H VOC Corp., Induceramic, Mingrui |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |