What is Global Explosion-proof Vibrator Market?

The Global Explosion-proof Vibrator Market is a specialized segment within the industrial equipment sector, focusing on devices designed to operate safely in hazardous environments where explosive gases, dust, or fibers may be present. These vibrators are crucial in industries such as mining, oil and gas, chemical processing, and food production, where safety is paramount. Explosion-proof vibrators are engineered to prevent any sparks or heat that could ignite a volatile atmosphere, ensuring the safety of both personnel and equipment. They are typically constructed with robust materials and sealed components to withstand harsh conditions and prevent the ingress of flammable substances. The market for these devices is driven by stringent safety regulations and the need for reliable equipment in hazardous locations. As industries continue to expand and prioritize safety, the demand for explosion-proof vibrators is expected to grow, with manufacturers focusing on innovation and compliance with international safety standards. This market is characterized by a diverse range of products, including electric, hydraulic, and pneumatic vibrators, each offering unique advantages depending on the specific application and environmental conditions.

Electric, Hydraulic, Pneumatic in the Global Explosion-proof Vibrator Market:

In the Global Explosion-proof Vibrator Market, three primary types of vibrators are utilized: electric, hydraulic, and pneumatic, each serving distinct purposes and offering unique benefits. Electric explosion-proof vibrators are widely used due to their efficiency and ease of installation. They are powered by electric motors and are designed to operate safely in explosive environments by containing any potential sparks within a sealed housing. These vibrators are ideal for applications requiring continuous operation and precise control, such as in manufacturing and processing plants. Their ability to provide consistent vibration makes them suitable for tasks like material handling and compaction. On the other hand, hydraulic explosion-proof vibrators are powered by hydraulic fluid and are known for their high power output and durability. They are particularly useful in heavy-duty applications where robust performance is required, such as in construction and mining. Hydraulic vibrators can generate significant force, making them effective for moving large volumes of material or breaking up compacted substances. Their sealed design ensures safe operation in explosive environments, and they are often preferred in situations where electric power is not readily available. Pneumatic explosion-proof vibrators, powered by compressed air, offer a versatile and safe solution for hazardous environments. They are lightweight and easy to install, making them suitable for portable applications. Pneumatic vibrators are often used in industries where electricity poses a risk, such as in chemical plants or grain silos. Their ability to operate without electrical components reduces the risk of sparks, making them inherently safe for explosive atmospheres. Additionally, pneumatic vibrators can be easily adjusted to provide varying levels of vibration, offering flexibility in different applications. Each type of explosion-proof vibrator has its own set of advantages, and the choice between electric, hydraulic, and pneumatic models depends on factors such as the specific application, environmental conditions, and available power sources. Manufacturers in the Global Explosion-proof Vibrator Market continue to innovate and improve these devices, focusing on enhancing safety features, efficiency, and ease of use to meet the evolving needs of industries operating in hazardous environments.

Power Plant, Silos, Conveying, Ohers in the Global Explosion-proof Vibrator Market:

The Global Explosion-proof Vibrator Market finds extensive usage across various sectors, including power plants, silos, conveying systems, and other industrial applications. In power plants, explosion-proof vibrators play a crucial role in ensuring the smooth operation of equipment and preventing the buildup of combustible dust. They are used to maintain the flow of materials such as coal, ash, and biomass, preventing blockages and ensuring efficient combustion processes. By providing consistent vibration, these devices help in the even distribution of materials, reducing the risk of hotspots and potential explosions. In silos, explosion-proof vibrators are essential for maintaining the flow of bulk materials like grains, cement, and chemicals. They prevent material bridging and rat-holing, ensuring that the contents of the silo are discharged smoothly and efficiently. This is particularly important in industries where the buildup of combustible dust can pose a significant safety hazard. By keeping the material moving, explosion-proof vibrators help prevent the accumulation of dust and reduce the risk of explosions. In conveying systems, these vibrators are used to enhance the movement of materials along conveyor belts, chutes, and hoppers. They ensure that materials do not become stuck or compacted, which can lead to blockages and equipment downtime. By maintaining a steady flow of materials, explosion-proof vibrators contribute to the overall efficiency and safety of the conveying process. Other industrial applications of explosion-proof vibrators include their use in chemical processing, food production, and mining. In these industries, the presence of flammable gases, dust, or fibers requires equipment that can operate safely without igniting the surrounding atmosphere. Explosion-proof vibrators provide the necessary vibration to move materials, mix ingredients, or compact products, all while ensuring the safety of personnel and equipment. As industries continue to prioritize safety and efficiency, the demand for explosion-proof vibrators is expected to grow, with manufacturers focusing on developing innovative solutions to meet the diverse needs of their customers.

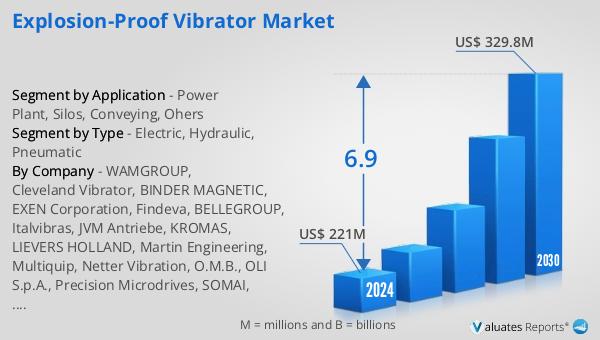

Global Explosion-proof Vibrator Market Outlook:

The worldwide market for explosion-proof vibrators was estimated to be worth $235 million in 2024. It is anticipated to expand to a revised valuation of $372 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.9% over the forecast period. This growth is driven by the increasing demand for safety in hazardous environments across various industries, including oil and gas, mining, and chemical processing. As companies continue to prioritize the safety of their operations and comply with stringent regulations, the need for reliable and efficient explosion-proof equipment is becoming more critical. The market's expansion is also fueled by technological advancements and innovations in product design, which enhance the performance and safety features of explosion-proof vibrators. Manufacturers are investing in research and development to create more efficient and durable products that can withstand the harsh conditions of explosive environments. Additionally, the growing awareness of workplace safety and the need to protect personnel and equipment from potential hazards are contributing to the market's growth. As industries continue to expand and explore new opportunities, the demand for explosion-proof vibrators is expected to rise, driving further growth in the market.

| Report Metric | Details |

| Report Name | Explosion-proof Vibrator Market |

| Accounted market size in year | US$ 235 million |

| Forecasted market size in 2031 | US$ 372 million |

| CAGR | 6.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | WAMGROUP, Cleveland Vibrator, BINDER MAGNETIC, EXEN Corporation, Findeva, BELLEGROUP, Italvibras, JVM Antriebe, KROMAS, LIEVERS HOLLAND, Martin Engineering, Multiquip, Netter Vibration, O.M.B., OLI S.p.A., Precision Microdrives, SOMAI, VIBCO, Martin Vibration, Houston Vibrator, Enmin Vibratory Equipment Pty Ltd, NAVCO, Vibratechniques Ltd, Kor Pak, VIBCO Vibrators, Adnil Pte, OLI Vibrators, Hindon Corporation, Deca Vibrator Industries Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |