What is Global Melamine Cyanurate Non-Halogenated Flame Retardant Market?

The Global Melamine Cyanurate Non-Halogenated Flame Retardant Market is a specialized segment within the broader flame retardant industry. This market focuses on melamine cyanurate, a compound known for its effectiveness in reducing flammability without the use of halogens, which are often associated with environmental and health concerns. Melamine cyanurate is particularly valued for its ability to enhance the fire resistance of various materials, making it a preferred choice in industries that prioritize safety and sustainability. The demand for non-halogenated flame retardants has been on the rise due to increasing regulatory pressures and growing awareness about the environmental impact of traditional flame retardants. As industries such as electronics, automotive, and construction continue to expand, the need for safer and more environmentally friendly flame retardant solutions like melamine cyanurate is expected to grow. This market is characterized by ongoing research and development efforts aimed at improving the performance and cost-effectiveness of melamine cyanurate-based products. Companies operating in this space are also focusing on strategic partnerships and collaborations to enhance their product offerings and expand their market reach. Overall, the Global Melamine Cyanurate Non-Halogenated Flame Retardant Market represents a dynamic and evolving sector with significant growth potential.

0.99, 0.98 in the Global Melamine Cyanurate Non-Halogenated Flame Retardant Market:

In the context of the Global Melamine Cyanurate Non-Halogenated Flame Retardant Market, the figures 0.99 and 0.98 could refer to specific grades or formulations of melamine cyanurate that are used in various applications. These numbers might indicate the purity level, particle size, or some other characteristic that differentiates one product from another. In the flame retardant industry, such specifications are crucial as they can significantly impact the performance of the flame retardant in different materials. For instance, a higher purity level might be required for applications in sensitive electronic components, where even minor impurities could affect the performance or safety of the final product. Similarly, the particle size could influence how well the flame retardant disperses within a polymer matrix, affecting its overall effectiveness. Companies in this market often offer a range of products with varying specifications to cater to the diverse needs of their customers. This flexibility allows manufacturers to tailor their products to specific applications, whether it's enhancing the fire resistance of a plastic component in a car or ensuring the safety of a building material. The choice between different grades like 0.99 and 0.98 would depend on the specific requirements of the application, as well as factors like cost, availability, and regulatory compliance. As the market for non-halogenated flame retardants continues to grow, the demand for specialized products with precise specifications is likely to increase. This trend underscores the importance of ongoing research and development efforts in this field, as companies strive to improve the performance and versatility of their products. By offering a range of options, manufacturers can better meet the needs of their customers and capitalize on the growing demand for safer, more sustainable flame retardant solutions. In summary, the figures 0.99 and 0.98 in the Global Melamine Cyanurate Non-Halogenated Flame Retardant Market likely represent specific product grades that cater to different application needs, highlighting the importance of product differentiation and customization in this evolving market.

Flame Retardant For Resin, Lubricant, Pore Agent, Others in the Global Melamine Cyanurate Non-Halogenated Flame Retardant Market:

The Global Melamine Cyanurate Non-Halogenated Flame Retardant Market finds its applications in several key areas, including flame retardants for resin, lubricants, pore agents, and others. In the realm of flame retardants for resin, melamine cyanurate is widely used to enhance the fire resistance of various polymeric materials. Resins are commonly used in industries such as electronics, automotive, and construction, where fire safety is a critical concern. By incorporating melamine cyanurate into resin formulations, manufacturers can significantly reduce the flammability of these materials, thereby improving their safety profile. This is particularly important in applications where the materials are exposed to high temperatures or potential ignition sources. In the lubricant industry, melamine cyanurate serves as an additive that can enhance the thermal stability and fire resistance of lubricants. Lubricants are essential in reducing friction and wear in machinery, but they can also pose a fire hazard if they ignite under high temperatures. By adding melamine cyanurate, manufacturers can improve the safety of their lubricants, making them suitable for use in high-temperature environments. This is particularly beneficial in industries such as automotive and manufacturing, where machinery operates under extreme conditions. As a pore agent, melamine cyanurate is used in the production of foamed materials. Pore agents are substances that create a cellular structure within a material, resulting in a lightweight and insulating product. Melamine cyanurate can be used to produce foamed plastics and other materials with enhanced fire resistance, making them suitable for applications in construction, packaging, and insulation. The use of melamine cyanurate as a pore agent not only improves the fire safety of these materials but also contributes to their overall performance and durability. In addition to these applications, melamine cyanurate is also used in other areas where fire resistance is a priority. This includes textiles, coatings, and adhesives, where the addition of a flame retardant can significantly enhance the safety and performance of the final product. As industries continue to prioritize safety and sustainability, the demand for non-halogenated flame retardants like melamine cyanurate is expected to grow. This trend is driven by increasing regulatory pressures and a growing awareness of the environmental and health impacts of traditional flame retardants. Overall, the Global Melamine Cyanurate Non-Halogenated Flame Retardant Market plays a crucial role in enhancing the fire safety of a wide range of materials and products, contributing to a safer and more sustainable future.

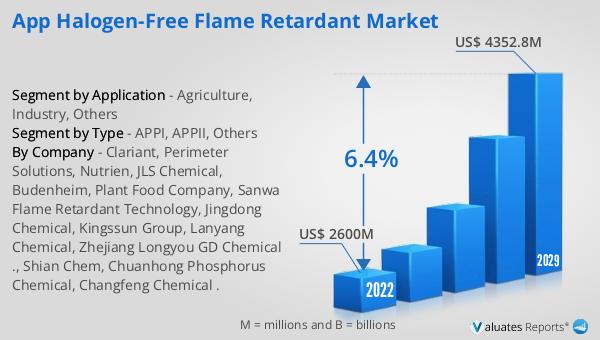

Global Melamine Cyanurate Non-Halogenated Flame Retardant Market Outlook:

The global market for Melamine Cyanurate Non-Halogenated Flame Retardant was valued at $2,637 million in 2024 and is anticipated to grow to a revised size of $3,969 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.1% during the forecast period. This growth trajectory underscores the increasing demand for safer and more environmentally friendly flame retardant solutions across various industries. As regulatory bodies worldwide continue to impose stricter guidelines on the use of halogenated flame retardants due to their potential environmental and health risks, industries are turning towards non-halogenated alternatives like melamine cyanurate. This shift is particularly evident in sectors such as electronics, automotive, and construction, where fire safety is paramount. The projected growth of the market is also indicative of the ongoing research and development efforts aimed at enhancing the performance and cost-effectiveness of melamine cyanurate-based products. Companies operating in this market are investing in innovative technologies and strategic partnerships to expand their product offerings and cater to the diverse needs of their customers. As the market continues to evolve, the focus on sustainability and safety is expected to drive further advancements in the development and application of non-halogenated flame retardants. Overall, the Global Melamine Cyanurate Non-Halogenated Flame Retardant Market is poised for significant growth, driven by increasing demand for safer, more sustainable flame retardant solutions.

| Report Metric | Details |

| Report Name | Melamine Cyanurate Non-Halogenated Flame Retardant Market |

| Accounted market size in year | US$ 2637 million |

| Forecasted market size in 2031 | US$ 3969 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ICL, Clariant, LANXESS, Nabaltech, BASF SE, Huber Engineered Materials, Akzo Nobel, DAIHACHI Chemical, Kyowa Chemical Industry, Momentive, Jiangsu Yoke Technology, Albemarle Corporation, Italmatch Chemicals, Zhejiang Wansheng, Jinan Taixing Fine Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |