What is Global Conductive/ESD Coatings Market?

The Global Conductive/ESD Coatings Market is a specialized segment within the broader coatings industry, focusing on materials that provide electrical conductivity and electrostatic discharge (ESD) protection. These coatings are essential in various industries where static electricity can cause significant damage to sensitive electronic components or where conductivity is required for specific applications. The market encompasses a range of products designed to prevent static buildup and ensure the safe operation of electronic devices. Conductive coatings are typically used to create a path for electrical current, while ESD coatings are specifically formulated to dissipate static charges. The demand for these coatings is driven by the increasing complexity and miniaturization of electronic devices, which are more susceptible to static damage. Additionally, industries such as aerospace, automotive, and medical devices require these coatings to ensure the reliability and safety of their products. As technology continues to advance, the need for effective conductive and ESD coatings is expected to grow, making this market a critical component of the global manufacturing landscape. The market's growth is also supported by regulatory standards that mandate the use of ESD protection in certain applications, further emphasizing the importance of these coatings in modern industry.

Conductive Coatings, ESD Coatings in the Global Conductive/ESD Coatings Market:

Conductive coatings and ESD coatings are integral to the Global Conductive/ESD Coatings Market, serving distinct yet complementary roles. Conductive coatings are designed to allow the flow of electrical current across a surface, which is crucial in applications where electrical conductivity is required. These coatings are often used in electronic devices to shield sensitive components from electromagnetic interference (EMI) and radio frequency interference (RFI). By providing a conductive path, these coatings help maintain the integrity of electronic signals and prevent disruptions. On the other hand, ESD coatings are specifically formulated to prevent the buildup of static electricity, which can cause significant damage to electronic components. Static discharge can lead to malfunctions or even complete failure of electronic devices, making ESD protection a critical consideration in the design and manufacturing of electronic products. ESD coatings work by dissipating static charges safely, ensuring that sensitive components are not exposed to harmful electrical discharges. The materials used in these coatings can vary, including metals, carbon, and conductive polymers, each offering different levels of conductivity and protection. The choice of material depends on the specific requirements of the application, such as the level of conductivity needed, environmental conditions, and compatibility with other materials. In the aerospace industry, for example, conductive coatings are used to protect aircraft components from lightning strikes and EMI, while ESD coatings ensure the safe operation of onboard electronics. In the automotive sector, these coatings are used to protect electronic control units and sensors, which are increasingly prevalent in modern vehicles. The medical device industry also relies on conductive and ESD coatings to ensure the reliability and safety of devices such as pacemakers and imaging equipment. Packaging is another area where these coatings are essential, particularly for the safe transport and storage of electronic components. By preventing static buildup, ESD coatings help protect sensitive items from damage during handling and shipping. Overall, the Global Conductive/ESD Coatings Market plays a vital role in ensuring the safety and reliability of a wide range of products across multiple industries. As technology continues to evolve, the demand for these coatings is expected to increase, driven by the need for enhanced protection and performance in electronic devices and systems.

Electronics & Semiconductors, Aerospace & Defense, Automotive, Medical Devices, Packaging, Others in the Global Conductive/ESD Coatings Market:

The usage of Global Conductive/ESD Coatings Market spans several critical industries, each with unique requirements and applications. In the electronics and semiconductors sector, these coatings are essential for protecting sensitive components from static discharge and electromagnetic interference. As electronic devices become more compact and complex, the risk of static damage increases, making ESD coatings a crucial part of the manufacturing process. These coatings help ensure the reliability and longevity of devices such as smartphones, computers, and other consumer electronics. In the aerospace and defense industry, conductive and ESD coatings are used to protect aircraft and military equipment from EMI and static discharge. These coatings are applied to various components, including avionics systems and communication devices, to ensure their safe and reliable operation in challenging environments. The automotive industry also benefits from these coatings, particularly as vehicles become more reliant on electronic systems. Conductive and ESD coatings are used to protect electronic control units, sensors, and other critical components from static damage and interference. In the medical devices sector, these coatings are used to ensure the safety and effectiveness of devices such as pacemakers, defibrillators, and imaging equipment. By preventing static discharge, these coatings help maintain the functionality and reliability of life-saving devices. Packaging is another area where conductive and ESD coatings are vital, particularly for the safe transport and storage of electronic components. These coatings help prevent static buildup during handling and shipping, reducing the risk of damage to sensitive items. Other industries, such as telecommunications and consumer electronics, also rely on these coatings to protect their products and ensure optimal performance. Overall, the Global Conductive/ESD Coatings Market plays a crucial role in supporting the safe and reliable operation of a wide range of products across multiple industries. As technology continues to advance, the demand for these coatings is expected to grow, driven by the need for enhanced protection and performance in electronic devices and systems.

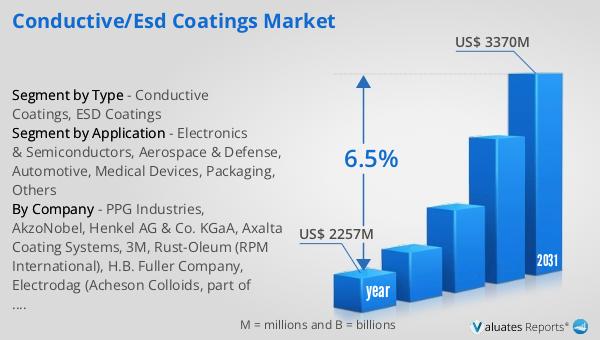

Global Conductive/ESD Coatings Market Outlook:

The outlook for the Global Conductive/ESD Coatings Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $2,257 million, reflecting its significant role in various industries. By 2031, it is anticipated to expand to a revised size of around $3,370 million. This growth is projected to occur at a compound annual growth rate (CAGR) of 6.5% over the forecast period. This upward trend underscores the increasing demand for conductive and ESD coatings across multiple sectors, driven by the rapid advancement of technology and the growing complexity of electronic devices. As industries continue to innovate and integrate more electronic components into their products, the need for effective protection against static discharge and electromagnetic interference becomes more critical. The market's expansion is also supported by stringent regulatory standards that require the use of ESD protection in certain applications, further emphasizing the importance of these coatings in modern manufacturing. As a result, companies operating in this market are likely to invest in research and development to create more advanced and efficient coatings, catering to the evolving needs of their customers. Overall, the Global Conductive/ESD Coatings Market is poised for significant growth, driven by technological advancements and the increasing demand for reliable and safe electronic products.

| Report Metric | Details |

| Report Name | Conductive/ESD Coatings Market |

| Accounted market size in year | US$ 2257 million |

| Forecasted market size in 2031 | US$ 3370 million |

| CAGR | 6.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PPG Industries, AkzoNobel, Henkel AG & Co. KGaA, Axalta Coating Systems, 3M, Rust-Oleum (RPM International), H.B. Fuller Company, Electrodag (Acheson Colloids, part of Henkel), MG Chemicals, Advanced Nano Products Co., Ltd., Nanomech Inc., Master Bond Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |