What is Global Magnetic Rope Testing Market?

The Global Magnetic Rope Testing Market is a specialized sector focused on the evaluation and maintenance of wire ropes using magnetic technologies. These ropes are critical components in various industries, including construction, mining, and transportation, where they are used for lifting, hoisting, and securing loads. Magnetic rope testing is a non-destructive method that helps in identifying internal and external flaws, such as corrosion, broken wires, and wear, which are not visible to the naked eye. This testing is crucial for ensuring the safety and reliability of operations, as undetected defects can lead to catastrophic failures. The market for magnetic rope testing is driven by the increasing demand for safety and efficiency in industrial operations, as well as the growing awareness of the benefits of regular maintenance and inspection. As industries continue to expand and modernize, the need for advanced testing methods like magnetic rope testing is expected to grow, making it an essential component of industrial safety protocols. The market is characterized by the presence of several key players who offer a range of testing solutions, from portable devices to sophisticated systems, catering to the diverse needs of different industries.

Magnetic Flux Leakage, Magnetoresistive Testing, Magnetic Memory Testing, Others in the Global Magnetic Rope Testing Market:

Magnetic Flux Leakage (MFL) is a widely used technique in the Global Magnetic Rope Testing Market. It involves magnetizing the wire rope and then detecting the leakage of magnetic flux caused by discontinuities such as broken wires or corrosion. When a rope is magnetized, the magnetic field lines travel through the rope, and any defect will cause a disturbance in these lines, resulting in a leakage field. Sensors detect this leakage, allowing for the identification of defects. MFL is valued for its ability to provide a comprehensive assessment of the rope's condition, offering insights into both surface and subsurface defects. This method is particularly useful in industries where safety is paramount, as it helps in preventing accidents by ensuring the integrity of the ropes used in critical operations. Magnetoresistive Testing (MRT) is another advanced technique employed in the magnetic rope testing market. It utilizes magnetoresistive sensors to detect changes in magnetic fields caused by defects in the rope. These sensors are highly sensitive and can detect minute changes in the magnetic field, making MRT an effective method for identifying even the smallest defects. This technique is often used in conjunction with other testing methods to provide a more detailed analysis of the rope's condition. MRT is particularly beneficial in applications where precision is crucial, such as in aerospace and marine industries, where even minor defects can have significant consequences. Magnetic Memory Testing (MMT) is a relatively newer technique that focuses on the magnetic memory of the material. It involves analyzing the residual magnetic field of the rope to identify areas of stress concentration, which are indicative of potential defects. MMT is based on the principle that materials retain a magnetic memory of the stresses they have been subjected to, and by analyzing this memory, it is possible to identify areas that are likely to fail. This method is particularly useful for predictive maintenance, as it allows for the identification of potential issues before they become critical. Other methods in the magnetic rope testing market include visual inspection and ultrasonic testing. Visual inspection is the most basic form of testing and involves a thorough examination of the rope for visible signs of wear and damage. While it is not as comprehensive as magnetic testing methods, it is still an important part of the overall inspection process. Ultrasonic testing, on the other hand, uses high-frequency sound waves to detect internal defects in the rope. This method is often used in conjunction with magnetic testing to provide a more complete assessment of the rope's condition. Each of these methods has its own advantages and limitations, and the choice of method depends on the specific requirements of the application. In conclusion, the Global Magnetic Rope Testing Market is characterized by a range of advanced testing methods, each offering unique benefits for ensuring the safety and reliability of wire ropes in various industries. As technology continues to advance, these methods are likely to become even more sophisticated, providing even greater insights into the condition of wire ropes and helping to prevent accidents and failures.

Construction Machinery, Energy and Infrastructure, Marine, Aerospace, Others in the Global Magnetic Rope Testing Market:

The Global Magnetic Rope Testing Market finds extensive usage across various sectors, each with its unique requirements and challenges. In the construction machinery sector, magnetic rope testing is crucial for ensuring the safety and reliability of cranes, hoists, and other lifting equipment. Construction sites are dynamic environments where safety is paramount, and the failure of a wire rope can lead to severe accidents and project delays. Regular magnetic rope testing helps in identifying potential defects early, allowing for timely maintenance and replacement, thereby minimizing the risk of accidents and ensuring smooth operations. In the energy and infrastructure sector, magnetic rope testing plays a vital role in the maintenance of equipment used in power plants, oil rigs, and other critical infrastructure. These environments often involve harsh conditions that can accelerate the wear and tear of wire ropes. Magnetic testing methods, such as Magnetic Flux Leakage and Magnetoresistive Testing, provide a non-destructive means of assessing the condition of ropes, ensuring that they are fit for use and reducing the risk of unexpected failures. This is particularly important in the energy sector, where equipment downtime can have significant financial and operational implications. The marine industry also relies heavily on magnetic rope testing to ensure the safety and reliability of ropes used in ships, offshore platforms, and other marine applications. The harsh marine environment, characterized by saltwater exposure and constant movement, can lead to rapid degradation of wire ropes. Magnetic testing methods help in detecting corrosion, broken wires, and other defects that can compromise the integrity of the ropes. By ensuring that ropes are in good condition, magnetic rope testing helps in preventing accidents and ensuring the safety of personnel and equipment in marine operations. In the aerospace sector, magnetic rope testing is used to ensure the safety and reliability of ropes used in aircraft and spacecraft. The aerospace industry demands the highest levels of precision and reliability, and even minor defects in ropes can have catastrophic consequences. Magnetic testing methods, such as Magnetoresistive Testing and Magnetic Memory Testing, provide a detailed analysis of the rope's condition, allowing for the identification of potential issues before they become critical. This is essential for maintaining the safety and reliability of aerospace operations. Other sectors, such as mining, transportation, and manufacturing, also benefit from the use of magnetic rope testing. In mining, for example, wire ropes are used in hoists and conveyors, where they are subjected to heavy loads and harsh conditions. Regular magnetic rope testing helps in identifying defects early, ensuring the safety and efficiency of mining operations. In transportation, magnetic rope testing is used to ensure the safety of ropes used in elevators, cable cars, and other applications. By providing a comprehensive assessment of the rope's condition, magnetic testing methods help in preventing accidents and ensuring the safety of passengers and equipment. In conclusion, the Global Magnetic Rope Testing Market plays a critical role in ensuring the safety and reliability of wire ropes across various sectors. By providing a non-destructive means of assessing the condition of ropes, magnetic testing methods help in identifying potential defects early, allowing for timely maintenance and replacement. This not only helps in preventing accidents and ensuring the safety of personnel and equipment but also contributes to the overall efficiency and reliability of operations. As industries continue to expand and modernize, the demand for advanced magnetic rope testing methods is expected to grow, making it an essential component of industrial safety protocols.

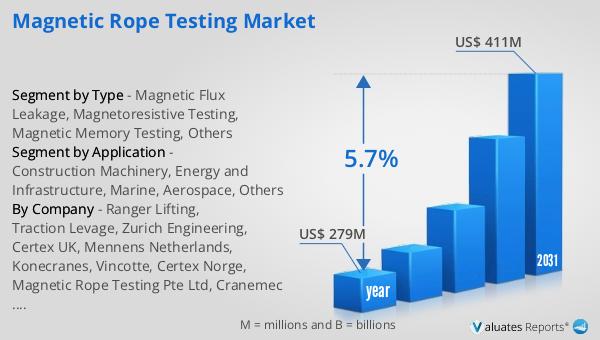

Global Magnetic Rope Testing Market Outlook:

The global market for Magnetic Rope Testing was valued at $279 million in 2024 and is anticipated to grow to a revised size of $411 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.7% over the forecast period. This growth is indicative of the increasing importance placed on safety and maintenance across various industries that rely on wire ropes for critical operations. As industries such as construction, energy, marine, and aerospace continue to expand and modernize, the demand for reliable and efficient testing methods is expected to rise. Magnetic rope testing offers a non-destructive means of assessing the condition of wire ropes, providing valuable insights into potential defects and areas of concern. This allows for timely maintenance and replacement, reducing the risk of accidents and ensuring the safety and reliability of operations. The market's growth is also driven by advancements in technology, which have led to the development of more sophisticated testing methods, such as Magnetic Flux Leakage, Magnetoresistive Testing, and Magnetic Memory Testing. These methods offer a more comprehensive assessment of the rope's condition, providing detailed insights into both surface and subsurface defects. As a result, industries are increasingly adopting magnetic rope testing as part of their regular maintenance and safety protocols. In conclusion, the Global Magnetic Rope Testing Market is poised for significant growth in the coming years, driven by the increasing demand for safety and efficiency in industrial operations. As technology continues to advance, the market is expected to see further innovations in testing methods, providing even greater insights into the condition of wire ropes and helping to prevent accidents and failures.

| Report Metric | Details |

| Report Name | Magnetic Rope Testing Market |

| Accounted market size in year | US$ 279 million |

| Forecasted market size in 2031 | US$ 411 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Ranger Lifting, Traction Levage, Zurich Engineering, Certex UK, Mennens Netherlands, Konecranes, Vincotte, Certex Norge, Magnetic Rope Testing Pte Ltd, Cranemec South Africa, TÜV AUSTRIA Belgium |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |