What is Global Mobile Machinery Main Control Valve Market?

The Global Mobile Machinery Main Control Valve Market is a specialized segment within the broader machinery and equipment industry. This market focuses on the production and distribution of main control valves, which are crucial components in mobile machinery. These valves are responsible for controlling the flow of hydraulic fluid within machinery, enabling precise operation and movement. The market encompasses a wide range of applications, including construction, agriculture, and shipbuilding, among others. As industries continue to advance technologically, the demand for efficient and reliable control valves has increased. This growth is driven by the need for enhanced performance, energy efficiency, and reduced environmental impact. Manufacturers in this market are continually innovating to meet these demands, offering products that are not only durable and efficient but also adaptable to various machinery types. The global reach of this market is significant, with key players operating in multiple regions, ensuring a steady supply of these essential components to meet the diverse needs of industries worldwide. As a result, the Global Mobile Machinery Main Control Valve Market plays a pivotal role in the functionality and efficiency of modern machinery.

Diameter 180, Diameter 180B, Diameter 750B in the Global Mobile Machinery Main Control Valve Market:

In the Global Mobile Machinery Main Control Valve Market, products such as Diameter 180, Diameter 180B, and Diameter 750B represent specific types of control valves that cater to different machinery requirements. Diameter 180 valves are typically used in smaller machinery where precision and compactness are crucial. These valves are designed to handle moderate flow rates and pressures, making them ideal for applications where space is limited but performance cannot be compromised. On the other hand, Diameter 180B valves are an advanced version, offering enhanced features such as improved flow control and durability. These valves are suitable for machinery that operates under more demanding conditions, providing reliable performance even in harsh environments. Diameter 750B valves, however, are designed for heavy-duty applications. These valves can handle high flow rates and pressures, making them indispensable in large machinery used in industries like construction and shipbuilding. The robust construction of Diameter 750B valves ensures they can withstand the rigors of continuous operation, providing consistent performance over extended periods. Each of these valve types is engineered to meet specific operational needs, ensuring that machinery operates efficiently and effectively. The choice between Diameter 180, 180B, and 750B depends on the specific requirements of the machinery, including factors such as size, operational environment, and performance expectations. Manufacturers in the Global Mobile Machinery Main Control Valve Market offer these products with various customization options, allowing end-users to select valves that best fit their machinery's needs. This flexibility is crucial in a market where machinery specifications can vary significantly across different industries and applications. As technology continues to evolve, these valves are also being integrated with smart technologies, enabling remote monitoring and control, which further enhances their functionality and appeal in the modern industrial landscape.

Construction Machinery, Agricultural Machinery, Shipbuilding, Other in the Global Mobile Machinery Main Control Valve Market:

The Global Mobile Machinery Main Control Valve Market finds extensive usage across various sectors, including construction machinery, agricultural machinery, shipbuilding, and other industries. In construction machinery, these control valves are vital for operating equipment such as excavators, loaders, and cranes. They ensure precise control of hydraulic functions, allowing for smooth and efficient operation of heavy machinery. The ability to manage hydraulic flow accurately is crucial in construction, where precision and safety are paramount. In agricultural machinery, main control valves are used in tractors, harvesters, and other equipment to control hydraulic systems that power implements and attachments. These valves help in optimizing the performance of agricultural machinery, ensuring that tasks such as plowing, planting, and harvesting are carried out efficiently. The reliability of these valves is essential in agriculture, where machinery downtime can lead to significant productivity losses. In the shipbuilding industry, main control valves are used in various applications, including steering systems, deck machinery, and cargo handling equipment. These valves play a critical role in ensuring the smooth operation of hydraulic systems on ships, contributing to the overall safety and efficiency of maritime operations. Other industries that utilize these valves include mining, forestry, and material handling, where they are used in equipment such as drills, feller bunchers, and forklifts. In each of these applications, the main control valves are designed to withstand the specific challenges of the industry, such as extreme temperatures, high pressures, and corrosive environments. The versatility and adaptability of these valves make them indispensable components in mobile machinery across diverse sectors. As industries continue to seek ways to improve efficiency and reduce environmental impact, the demand for advanced control valves that offer enhanced performance and reliability is expected to grow.

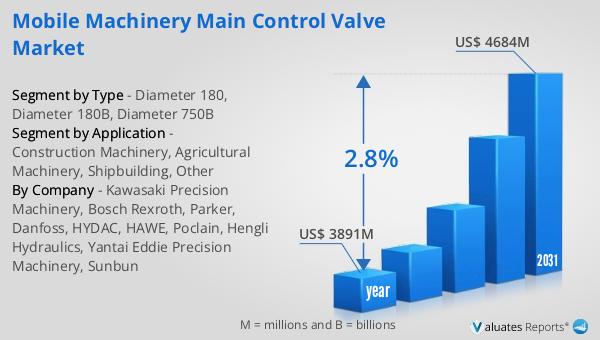

Global Mobile Machinery Main Control Valve Market Outlook:

The outlook for the Global Mobile Machinery Main Control Valve Market indicates a steady growth trajectory. In 2024, the market was valued at approximately US$ 3,891 million. By 2031, it is anticipated to expand to a revised size of US$ 4,684 million, reflecting a compound annual growth rate (CAGR) of 2.8% over the forecast period. This growth is driven by several factors, including the increasing demand for mobile machinery across various industries and the ongoing advancements in valve technology. As industries such as construction, agriculture, and shipbuilding continue to evolve, the need for efficient and reliable control valves becomes more pronounced. Manufacturers are responding to this demand by developing innovative products that offer improved performance, durability, and energy efficiency. Additionally, the integration of smart technologies into control valves is enhancing their functionality, allowing for remote monitoring and control, which is particularly beneficial in industries where machinery operates in challenging environments. The global reach of this market ensures that key players can supply these essential components to meet the diverse needs of industries worldwide. As a result, the Global Mobile Machinery Main Control Valve Market is poised for continued growth, playing a crucial role in the functionality and efficiency of modern machinery.

| Report Metric | Details |

| Report Name | Mobile Machinery Main Control Valve Market |

| Accounted market size in year | US$ 3891 million |

| Forecasted market size in 2031 | US$ 4684 million |

| CAGR | 2.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kawasaki Precision Machinery, Bosch Rexroth, Parker, Danfoss, HYDAC, HAWE, Poclain, Hengli Hydraulics, Yantai Eddie Precision Machinery, Sunbun |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |