What is Global Cleanroom Automation Robots Market?

The Global Cleanroom Automation Robots Market is a specialized segment within the broader robotics industry, focusing on the development and deployment of robots designed for cleanroom environments. Cleanrooms are controlled spaces where pollutants like dust, airborne microbes, and chemical vapors are minimized, making them essential in industries that require high levels of cleanliness and precision. Automation robots in these settings are engineered to perform tasks without introducing contaminants, thereby maintaining the integrity of the cleanroom environment. These robots are equipped with advanced sensors and software to navigate and operate efficiently in such controlled settings. The market for these robots is driven by the increasing demand for precision and efficiency in industries such as pharmaceuticals, semiconductors, and biotechnology, where even the smallest contamination can lead to significant product defects or failures. As technology advances, these robots are becoming more sophisticated, offering enhanced capabilities such as machine learning and artificial intelligence to further optimize cleanroom operations. The growth of this market is also fueled by the need for cost-effective solutions that can operate continuously without human intervention, thereby reducing labor costs and increasing productivity.

Handling Robots, Inspection Robots, Assembly Robots, Packaging Robots, Transport Robots, Sorting Robots in the Global Cleanroom Automation Robots Market:

Handling Robots in the Global Cleanroom Automation Robots Market are designed to manage and manipulate materials or products within a cleanroom environment. These robots are equipped with precision grippers and sensors to handle delicate items without causing contamination or damage. They are commonly used in industries like pharmaceuticals and semiconductors, where they can transport materials between different stages of production with high accuracy. Inspection Robots, on the other hand, are tasked with examining products or components to ensure they meet specific quality standards. These robots use advanced imaging technologies and sensors to detect defects or inconsistencies, playing a crucial role in quality control processes. Assembly Robots are utilized to put together components or products in a cleanroom setting. They are designed to perform repetitive tasks with high precision, reducing the risk of human error and contamination. These robots are particularly valuable in the electronics and medical device industries, where precision assembly is critical. Packaging Robots are responsible for packing products in a manner that maintains their sterility and integrity. They are equipped with specialized tools to handle packaging materials and products without compromising cleanliness. Transport Robots are used to move materials or products within the cleanroom, ensuring efficient workflow and minimizing human intervention. These robots are often autonomous, using sensors and mapping technologies to navigate the cleanroom environment safely. Sorting Robots are designed to organize products or components based on specific criteria, such as size, shape, or type. They use advanced algorithms and sensors to accurately sort items, enhancing the efficiency of production processes. Each type of robot plays a vital role in maintaining the cleanliness and efficiency of cleanroom operations, contributing to the overall productivity and quality of the industries they serve.

Semiconductor, Pharmaceutical, Medical Device, Electronics, Laboratories, Aerospace, Others in the Global Cleanroom Automation Robots Market:

The usage of Global Cleanroom Automation Robots Market spans several critical industries, each benefiting from the precision and efficiency these robots offer. In the semiconductor industry, cleanroom robots are essential for handling delicate wafers and components, ensuring that they remain free from contaminants that could affect their performance. These robots are used in various stages of semiconductor manufacturing, from wafer fabrication to packaging, where precision and cleanliness are paramount. In the pharmaceutical industry, cleanroom robots are employed to handle and process drugs and other medical products. They help maintain the sterility of the production environment, reducing the risk of contamination and ensuring that products meet stringent regulatory standards. Medical device manufacturing also relies heavily on cleanroom robots to assemble and package devices with high precision, ensuring their safety and efficacy. In the electronics industry, cleanroom robots are used to assemble and test components, ensuring that they function correctly and meet quality standards. Laboratories utilize these robots for tasks such as sample handling and analysis, where precision and contamination control are crucial. In the aerospace industry, cleanroom robots are used to manufacture and assemble components that require high levels of precision and cleanliness. Other industries, such as biotechnology and food processing, also benefit from the use of cleanroom robots, which help maintain product quality and safety. Overall, the use of cleanroom automation robots across these industries highlights their importance in maintaining high standards of cleanliness and precision, ultimately contributing to the production of high-quality products.

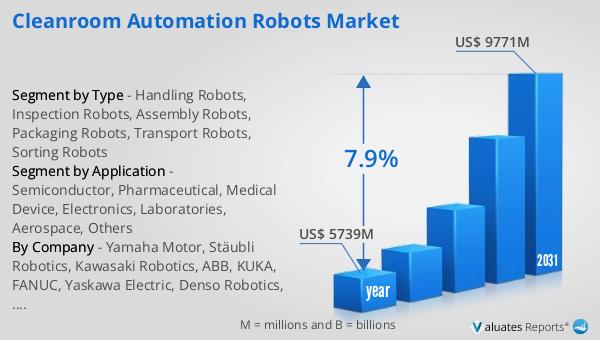

Global Cleanroom Automation Robots Market Outlook:

The outlook for the Global Cleanroom Automation Robots Market indicates a promising future, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately $5,739 million, reflecting the increasing demand for automation solutions in cleanroom environments. This demand is driven by the need for precision, efficiency, and contamination control in industries such as pharmaceuticals, semiconductors, and biotechnology. By 2031, the market is projected to reach a revised size of $9,771 million, growing at a compound annual growth rate (CAGR) of 7.9% during the forecast period. This growth is attributed to advancements in robotics technology, including the integration of artificial intelligence and machine learning, which enhance the capabilities of cleanroom robots. Additionally, the increasing adoption of automation in various industries to reduce labor costs and improve productivity is expected to drive market growth. As companies continue to invest in cleanroom automation solutions, the market is poised to expand, offering new opportunities for innovation and development. The projected growth underscores the importance of cleanroom automation robots in maintaining high standards of cleanliness and precision, ultimately contributing to the production of high-quality products across various industries.

| Report Metric | Details |

| Report Name | Cleanroom Automation Robots Market |

| Accounted market size in year | US$ 5739 million |

| Forecasted market size in 2031 | US$ 9771 million |

| CAGR | 7.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Yamaha Motor, Stäubli Robotics, Kawasaki Robotics, ABB, KUKA, FANUC, Yaskawa Electric, Denso Robotics, Epson Robots, Nachi-Fujikoshi, Mitsubishi Electric, Universal Robots, HIWIN Technologies, HIRATA, RORZE, Shibaura Machine |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |