What is Global Molecular Drag Pumps Market?

The Global Molecular Drag Pumps Market is a specialized segment within the vacuum pump industry, focusing on devices that utilize molecular drag principles to achieve high vacuum levels. These pumps are essential in various high-tech applications due to their ability to efficiently handle low-pressure environments. Molecular drag pumps operate by using a rotor that spins at high speeds, creating a drag force that moves gas molecules from the inlet to the exhaust. This mechanism is particularly effective in achieving the high vacuum levels required in industries such as semiconductor manufacturing, thin-film deposition, and analytical instrumentation. The market for these pumps is driven by the increasing demand for advanced manufacturing processes and the miniaturization of electronic components. As industries continue to push the boundaries of technology, the need for reliable and efficient vacuum solutions like molecular drag pumps is expected to grow. The market is characterized by continuous innovation, with manufacturers focusing on improving pump efficiency, reducing energy consumption, and enhancing durability. Overall, the Global Molecular Drag Pumps Market plays a crucial role in supporting the technological advancements of various high-tech industries by providing the necessary vacuum conditions for their operations.

Low-Speed Gaede Type (5–50 L/s), High-Speed Holweck Type (50–500 L/s), Compound Molecular Drag Type (>500 L/s) in the Global Molecular Drag Pumps Market:

In the Global Molecular Drag Pumps Market, different types of pumps cater to various needs based on their speed and capacity. The Low-Speed Gaede Type, with a capacity ranging from 5 to 50 liters per second (L/s), is designed for applications that require moderate vacuum levels. These pumps are often used in laboratory settings and small-scale industrial applications where precise control over vacuum conditions is necessary. The Gaede Type pumps operate by utilizing a series of rotating disks that create a drag force, effectively moving gas molecules through the pump. This type of pump is known for its reliability and ease of maintenance, making it a popular choice for applications that do not require extremely high vacuum levels. On the other hand, the High-Speed Holweck Type, with a capacity of 50 to 500 L/s, is suitable for more demanding applications that require higher vacuum levels. These pumps use a helical groove design on the rotor, which enhances the drag force and allows for faster evacuation of gas molecules. The Holweck Type pumps are commonly used in semiconductor manufacturing and other high-tech industries where maintaining a high vacuum is critical for process efficiency and product quality. Finally, the Compound Molecular Drag Type, with a capacity exceeding 500 L/s, is designed for the most demanding applications that require ultra-high vacuum levels. These pumps combine the principles of both Gaede and Holweck designs, offering the advantages of both types in a single unit. The Compound Molecular Drag Type pumps are often used in large-scale industrial applications, such as thin-film deposition and advanced research facilities, where maintaining an ultra-high vacuum is essential for achieving the desired results. These pumps are known for their high efficiency, durability, and ability to handle large volumes of gas, making them an indispensable tool in the Global Molecular Drag Pumps Market. Overall, the different types of molecular drag pumps cater to a wide range of applications, each offering unique advantages based on their design and capacity.

Semiconductor, Photovoltaics & Battery, Thin Film & Coating, LED & Display, Analytical Instruments, Others in the Global Molecular Drag Pumps Market:

The Global Molecular Drag Pumps Market finds extensive usage across various high-tech industries, each benefiting from the unique capabilities of these pumps. In the semiconductor industry, molecular drag pumps are crucial for processes such as chemical vapor deposition and etching, where maintaining a high vacuum is essential for achieving precise and consistent results. These pumps help in removing contaminants and ensuring a clean environment, which is vital for the production of high-quality semiconductor devices. Similarly, in the photovoltaics and battery industry, molecular drag pumps are used in the manufacturing of solar cells and battery components. The high vacuum conditions provided by these pumps are necessary for processes like thin-film deposition, which is critical for enhancing the efficiency and performance of solar panels and batteries. In the thin film and coating industry, molecular drag pumps are used to create the vacuum conditions required for depositing thin layers of material onto various substrates. This process is essential for producing coatings with specific properties, such as increased hardness, corrosion resistance, or optical clarity. The LED and display industry also relies on molecular drag pumps for the production of high-quality displays and lighting solutions. These pumps help in maintaining the vacuum conditions necessary for processes like organic light-emitting diode (OLED) deposition, which is crucial for achieving the desired brightness and color accuracy in displays. In the field of analytical instruments, molecular drag pumps are used in mass spectrometers and electron microscopes, where maintaining a high vacuum is essential for accurate measurements and imaging. These pumps help in removing air and other contaminants, ensuring that the instruments can operate at their full potential. Finally, molecular drag pumps are also used in various other industries, such as aerospace, medical devices, and research laboratories, where maintaining a high vacuum is critical for achieving the desired results. Overall, the Global Molecular Drag Pumps Market plays a vital role in supporting the technological advancements of these industries by providing the necessary vacuum conditions for their operations.

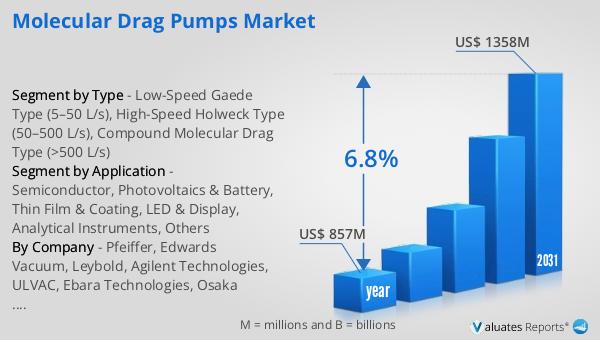

Global Molecular Drag Pumps Market Outlook:

The global market for Molecular Drag Pumps was valued at $857 million in 2024, and it is anticipated to expand to a revised size of $1,358 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.8% over the forecast period. This growth trajectory underscores the increasing demand for molecular drag pumps across various high-tech industries. As industries continue to evolve and adopt more advanced manufacturing processes, the need for efficient and reliable vacuum solutions becomes more critical. Molecular drag pumps, with their ability to achieve high vacuum levels, are well-positioned to meet this demand. The market's growth is driven by factors such as the miniaturization of electronic components, the increasing complexity of manufacturing processes, and the need for high precision in industries like semiconductors, photovoltaics, and analytical instruments. Manufacturers in the market are focusing on innovation, aiming to improve pump efficiency, reduce energy consumption, and enhance durability to meet the evolving needs of their customers. As a result, the Global Molecular Drag Pumps Market is expected to continue its upward trajectory, playing a crucial role in supporting the technological advancements of various high-tech industries.

| Report Metric | Details |

| Report Name | Molecular Drag Pumps Market |

| Accounted market size in year | US$ 857 million |

| Forecasted market size in 2031 | US$ 1358 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Pfeiffer, Edwards Vacuum, Leybold, Agilent Technologies, ULVAC, Ebara Technologies, Osaka Vacuum, Shimadzu, Busch Vacuum, Becker Pumps, Yuanhua Industrial, Duniway Stockroom |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |