What is Global Matrix Body PDC Drill Bit Market?

The Global Matrix Body PDC Drill Bit Market is a specialized segment within the broader drilling industry, focusing on the production and distribution of matrix body polycrystalline diamond compact (PDC) drill bits. These drill bits are essential tools in the oil and gas industry, as well as in mining and construction, due to their durability and efficiency in cutting through hard rock formations. The matrix body PDC drill bits are constructed using a composite material that combines diamond particles with a metallic binder, resulting in a tool that offers superior wear resistance and longevity compared to traditional steel body drill bits. This market is driven by the increasing demand for energy and natural resources, which necessitates advanced drilling technologies to access deeper and more challenging reserves. Additionally, the ongoing advancements in PDC technology, such as improved cutter designs and enhanced thermal stability, are contributing to the growth of this market by enabling more efficient and cost-effective drilling operations. As industries continue to seek ways to optimize their drilling processes, the Global Matrix Body PDC Drill Bit Market is poised to play a crucial role in meeting these demands.

5 Blades, 6 Blades, 7 Blades, Others in the Global Matrix Body PDC Drill Bit Market:

In the Global Matrix Body PDC Drill Bit Market, the number of blades on a drill bit is a critical factor that influences its performance and suitability for different drilling conditions. Drill bits with 5 blades are often used in applications where a balance between speed and durability is required. These bits are designed to provide efficient cutting action while maintaining structural integrity, making them suitable for medium-hard formations. The 5-blade configuration allows for a moderate rate of penetration and is often favored in scenarios where drilling speed is a priority but not at the expense of bit life. On the other hand, 6-blade drill bits are engineered for more challenging drilling environments. The additional blade increases the bit's stability and cutting efficiency, allowing it to handle harder rock formations with ease. This configuration is particularly beneficial in applications where maintaining a consistent rate of penetration is crucial, such as in deep well drilling. The 6-blade design also helps in reducing bit whirl, which can lead to premature wear and tear. Moving to 7-blade drill bits, these are typically used in the most demanding drilling conditions. The increased number of blades provides enhanced stability and cutting performance, making them ideal for extremely hard and abrasive formations. The 7-blade configuration allows for a smoother drilling operation, reducing vibrations and improving the overall lifespan of the bit. This makes them a preferred choice in high-pressure, high-temperature drilling environments where precision and durability are paramount. In addition to these standard configurations, the Global Matrix Body PDC Drill Bit Market also offers other blade designs tailored to specific drilling needs. These may include bits with specialized cutter geometries or hybrid designs that combine the benefits of different blade counts. Such innovations are driven by the need to optimize drilling performance in unique geological conditions, ensuring that operators can achieve their objectives efficiently and cost-effectively. As the demand for more advanced drilling solutions continues to grow, the diversity in blade configurations within the Global Matrix Body PDC Drill Bit Market is expected to expand, offering operators a wider range of options to suit their specific requirements.

Tunnels, Mines, Natural Gas, Petroleum, Others in the Global Matrix Body PDC Drill Bit Market:

The Global Matrix Body PDC Drill Bit Market finds extensive usage across various sectors, including tunnels, mines, natural gas, petroleum, and others, due to its superior cutting capabilities and durability. In tunnel construction, these drill bits are essential for boring through hard rock formations, enabling the creation of underground passages for transportation and utilities. The matrix body PDC drill bits are favored in this sector for their ability to maintain a high rate of penetration while minimizing wear, which is crucial in large-scale tunneling projects where time and cost efficiency are paramount. In the mining industry, these drill bits are used for both exploration and extraction purposes. Their robust design allows them to withstand the harsh conditions often encountered in mining operations, such as high temperatures and abrasive materials. This makes them ideal for drilling through various types of rock to access valuable minerals and ores. The natural gas sector also relies heavily on matrix body PDC drill bits for drilling wells to extract gas from underground reservoirs. The efficiency and longevity of these bits are particularly beneficial in this industry, where drilling operations can be both time-consuming and costly. By reducing the frequency of bit replacements and enhancing drilling speed, matrix body PDC drill bits contribute to more economical and efficient gas extraction processes. Similarly, in the petroleum industry, these drill bits are used extensively for oil well drilling. The ability of matrix body PDC drill bits to handle high-pressure, high-temperature environments makes them indispensable tools in the quest to access deeper and more challenging oil reserves. Their advanced design ensures that they can cut through tough geological formations with precision, reducing the risk of operational delays and equipment failures. Beyond these primary sectors, matrix body PDC drill bits are also utilized in other areas such as geothermal energy exploration and water well drilling. In geothermal projects, the ability to drill efficiently through hard rock is crucial for accessing the heat stored beneath the Earth's surface. Meanwhile, in water well drilling, these bits provide a reliable solution for creating boreholes in various geological conditions. Overall, the versatility and performance of matrix body PDC drill bits make them a valuable asset across multiple industries, driving their demand in the global market.

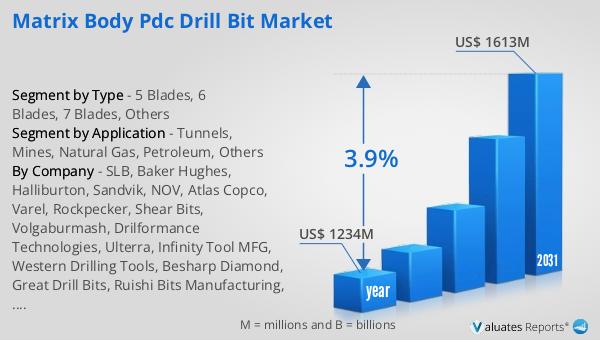

Global Matrix Body PDC Drill Bit Market Outlook:

The worldwide market for Matrix Body PDC Drill Bits was valued at $1,234 million in 2024 and is anticipated to grow to a revised size of $1,613 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. This growth trajectory underscores the increasing demand for advanced drilling technologies across various industries, including oil and gas, mining, and construction. The steady rise in market value is indicative of the ongoing advancements in PDC technology, which are enhancing the efficiency and durability of drill bits. As industries continue to seek more cost-effective and reliable drilling solutions, the Matrix Body PDC Drill Bit Market is expected to play a pivotal role in meeting these needs. The projected growth also highlights the importance of these drill bits in accessing deeper and more challenging reserves, as well as their ability to withstand harsh drilling conditions. With the continuous development of new materials and designs, the market is poised to offer even more innovative solutions to address the evolving demands of the drilling industry. As a result, the Matrix Body PDC Drill Bit Market is set to remain a key player in the global drilling landscape, driving technological advancements and supporting the exploration and extraction of valuable resources.

| Report Metric | Details |

| Report Name | Matrix Body PDC Drill Bit Market |

| Accounted market size in year | US$ 1234 million |

| Forecasted market size in 2031 | US$ 1613 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SLB, Baker Hughes, Halliburton, Sandvik, NOV, Atlas Copco, Varel, Rockpecker, Shear Bits, Volgaburmash, Drilformance Technologies, Ulterra, Infinity Tool MFG, Western Drilling Tools, Besharp Diamond, Great Drill Bits, Ruishi Bits Manufacturing, Deepbit, Fulaimei Drilling Equipment, Chuanshi Diamond Bit, Hongli Rock Bits, Hebei Crossing Drill Bit |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |