What is Global Automatic Wave Solder System Market?

The Global Automatic Wave Solder System Market refers to the industry focused on the production and distribution of wave soldering machines that automate the process of soldering electronic components onto printed circuit boards (PCBs). These systems are crucial in the electronics manufacturing sector, as they ensure efficient and reliable soldering, which is essential for the functionality and durability of electronic devices. The market encompasses various types of wave soldering systems, including conventional and selective wave soldering machines, each designed to meet specific manufacturing needs. The demand for these systems is driven by the growing electronics industry, which requires advanced soldering solutions to keep up with the increasing complexity and miniaturization of electronic components. As technology continues to evolve, the Global Automatic Wave Solder System Market is expected to expand, offering more sophisticated and efficient soldering solutions to meet the demands of modern electronics manufacturing. This market plays a vital role in ensuring the quality and performance of electronic products, making it an essential component of the global electronics supply chain.

Conventional Wave Soldering, Selective Wave Soldering in the Global Automatic Wave Solder System Market:

Conventional wave soldering is a widely used technique in the Global Automatic Wave Solder System Market, primarily employed for soldering through-hole components on PCBs. This method involves passing the PCB over a wave of molten solder, which ensures that the solder adheres to the exposed metal areas of the board, creating strong electrical connections. The process begins with the application of flux to the PCB, which cleans and prepares the metal surfaces for soldering. The board is then preheated to activate the flux and prevent thermal shock during soldering. As the PCB moves over the solder wave, the molten solder flows over the board, soldering the components in place. This method is highly efficient for mass production, as it allows for the simultaneous soldering of multiple components, reducing manufacturing time and costs. However, conventional wave soldering is not suitable for surface-mount technology (SMT) components, which require a different approach. Selective wave soldering, on the other hand, is designed to address the limitations of conventional wave soldering, particularly when dealing with mixed-technology PCBs that include both through-hole and SMT components. This method allows for precise soldering of specific areas on the PCB, avoiding damage to sensitive SMT components. In selective wave soldering, the PCB is positioned over a small, controlled wave of solder, which is directed only at the areas requiring soldering. This targeted approach minimizes the risk of thermal damage to the board and components, making it ideal for complex assemblies. The process involves the use of a programmable soldering machine that can be customized to accommodate different board designs and component layouts. Selective wave soldering is particularly beneficial for low to medium-volume production runs, where flexibility and precision are more critical than speed. It also reduces the need for manual touch-ups, improving overall production efficiency and product quality. Both conventional and selective wave soldering play crucial roles in the Global Automatic Wave Solder System Market, catering to different manufacturing needs and challenges. As the electronics industry continues to evolve, the demand for advanced soldering solutions is expected to grow, driving innovation and development in this market. Manufacturers are continually seeking ways to improve the efficiency, precision, and reliability of wave soldering systems to meet the increasing demands of modern electronics production. This includes the integration of advanced technologies such as automation, robotics, and artificial intelligence, which enhance the capabilities of wave soldering systems and enable manufacturers to achieve higher levels of productivity and quality. The Global Automatic Wave Solder System Market is poised for significant growth as it adapts to the changing landscape of electronics manufacturing, providing essential solutions for the production of high-quality electronic devices.

Consumer Electronics, Automotive Electronics, Industrial Controls, Others in the Global Automatic Wave Solder System Market:

The Global Automatic Wave Solder System Market finds extensive application across various sectors, including consumer electronics, automotive electronics, industrial controls, and others. In the consumer electronics sector, wave soldering systems are essential for the mass production of devices such as smartphones, tablets, laptops, and home appliances. These systems ensure the efficient and reliable soldering of electronic components onto PCBs, which is crucial for the performance and durability of consumer electronics. As the demand for smaller, more powerful, and feature-rich devices continues to grow, manufacturers rely on advanced wave soldering systems to meet these requirements while maintaining high production standards. In the automotive electronics sector, wave soldering systems play a vital role in the production of electronic control units (ECUs), sensors, and other critical components used in modern vehicles. The automotive industry demands high levels of precision and reliability, as electronic components are integral to the safety and functionality of vehicles. Automatic wave soldering systems provide the necessary accuracy and consistency required for the production of automotive electronics, ensuring that components meet stringent quality standards. As vehicles become increasingly reliant on electronic systems for functions such as navigation, entertainment, and driver assistance, the demand for advanced wave soldering solutions is expected to rise. Industrial controls represent another significant application area for the Global Automatic Wave Solder System Market. In this sector, wave soldering systems are used to produce electronic components for machinery, automation systems, and other industrial equipment. These components must withstand harsh operating conditions and provide reliable performance over extended periods. Automatic wave soldering systems offer the precision and durability needed to produce high-quality industrial electronics, enabling manufacturers to meet the demands of this challenging sector. As industries continue to embrace automation and digitalization, the need for advanced wave soldering solutions is likely to increase. Beyond these primary sectors, the Global Automatic Wave Solder System Market also serves other industries, including telecommunications, aerospace, and medical devices. In telecommunications, wave soldering systems are used to produce components for network infrastructure and communication devices, which require high levels of reliability and performance. In the aerospace industry, wave soldering systems are employed in the production of avionics and other critical electronic systems, where precision and quality are paramount. Similarly, in the medical devices sector, wave soldering systems are used to produce components for diagnostic equipment, monitoring devices, and other healthcare technologies, where reliability and safety are essential. The versatility and adaptability of automatic wave soldering systems make them indispensable across a wide range of industries, driving their continued growth and development in the global market.

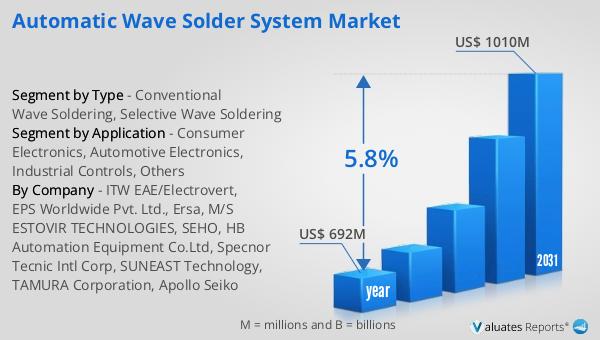

Global Automatic Wave Solder System Market Outlook:

In 2024, the global market for Automatic Wave Solder Systems was valued at approximately $692 million. This market is anticipated to grow significantly, reaching an estimated size of $1,010 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.8% over the forecast period. The expansion of this market can be attributed to several factors, including the increasing demand for advanced electronic devices across various industries, such as consumer electronics, automotive, and industrial controls. As technology continues to evolve, the need for efficient and reliable soldering solutions becomes more critical, driving the adoption of automatic wave soldering systems. These systems offer numerous advantages, including improved production efficiency, enhanced product quality, and reduced manufacturing costs, making them an attractive investment for manufacturers. Additionally, the integration of advanced technologies, such as automation and robotics, into wave soldering systems is expected to further boost their capabilities and appeal. As a result, the Global Automatic Wave Solder System Market is poised for substantial growth, providing essential solutions for the production of high-quality electronic devices across various sectors. This market outlook highlights the significant potential for growth and innovation in the automatic wave soldering industry, as it continues to adapt to the changing demands of modern electronics manufacturing.

| Report Metric | Details |

| Report Name | Automatic Wave Solder System Market |

| Accounted market size in year | US$ 692 million |

| Forecasted market size in 2031 | US$ 1010 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITW EAE/Electrovert, EPS Worldwide Pvt. Ltd., Ersa, M/S ESTOVIR TECHNOLOGIES, SEHO, HB Automation Equipment Co.Ltd, Specnor Tecnic Intl Corp, SUNEAST Technology, TAMURA Corporation, Apollo Seiko |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |