What is Global Industrial Tank and Equipment Cleaning Nozzle Market?

The Global Industrial Tank and Equipment Cleaning Nozzle Market is a specialized sector within the broader industrial cleaning industry, focusing on the development and distribution of nozzles designed for cleaning tanks and equipment. These nozzles are crucial for maintaining hygiene and operational efficiency in various industries, including food and beverage, pharmaceuticals, chemicals, and oil and gas. The market encompasses a wide range of nozzle types, each engineered to meet specific cleaning requirements, such as removing residues, preventing contamination, and ensuring compliance with industry standards. The demand for these nozzles is driven by the need for efficient cleaning solutions that minimize downtime and reduce labor costs. As industries continue to prioritize cleanliness and operational efficiency, the market for industrial tank and equipment cleaning nozzles is expected to grow, with innovations focusing on improving cleaning performance, durability, and ease of use. The market is characterized by a mix of established players and emerging companies, all striving to offer advanced solutions that cater to the diverse needs of their clients.

Fixed Cleaning Nozzle, Rotating Cleaning Nozzle in the Global Industrial Tank and Equipment Cleaning Nozzle Market:

Fixed cleaning nozzles and rotating cleaning nozzles are two primary types of nozzles used in the Global Industrial Tank and Equipment Cleaning Nozzle Market, each serving distinct purposes and offering unique benefits. Fixed cleaning nozzles are stationary devices that deliver a consistent spray pattern, making them ideal for applications where uniform coverage is essential. These nozzles are often used in scenarios where the cleaning requirements are straightforward and do not necessitate complex movements. They are typically more cost-effective and easier to maintain due to their simple design. Fixed nozzles are commonly employed in industries where tanks and equipment have standard shapes and sizes, allowing for predictable cleaning patterns. On the other hand, rotating cleaning nozzles are designed to provide dynamic cleaning action by rotating during operation. This rotation allows them to cover a larger surface area and reach difficult-to-clean spots, making them suitable for more complex cleaning tasks. Rotating nozzles are often used in industries where tanks and equipment have intricate designs or where residues are particularly stubborn. These nozzles are engineered to deliver high-impact cleaning, which is essential for removing tough deposits and ensuring thorough sanitation. The choice between fixed and rotating nozzles depends on several factors, including the nature of the residue, the design of the equipment, and the desired cleaning outcome. In many cases, industries may use a combination of both types to achieve optimal cleaning results. The market for these nozzles is driven by the need for efficient and reliable cleaning solutions that can adapt to various industrial requirements. Manufacturers are continually innovating to enhance the performance and durability of both fixed and rotating nozzles, incorporating advanced materials and technologies to meet the evolving demands of their clients. As industries continue to prioritize cleanliness and operational efficiency, the demand for both fixed and rotating cleaning nozzles is expected to grow, with a focus on developing solutions that offer superior cleaning performance and ease of use.

Tank Cleaning, Industrial Machinery Cleaning in the Global Industrial Tank and Equipment Cleaning Nozzle Market:

The Global Industrial Tank and Equipment Cleaning Nozzle Market plays a crucial role in various applications, particularly in tank cleaning and industrial machinery cleaning. In tank cleaning, these nozzles are essential for maintaining hygiene and preventing contamination in industries such as food and beverage, pharmaceuticals, and chemicals. Tanks used in these industries often store sensitive materials that require stringent cleaning protocols to ensure product safety and quality. Cleaning nozzles are designed to deliver precise and effective cleaning, removing residues and preventing the buildup of harmful bacteria or contaminants. The use of specialized nozzles allows for efficient cleaning processes that minimize downtime and reduce labor costs, ultimately enhancing operational efficiency. In industrial machinery cleaning, nozzles are used to maintain the performance and longevity of equipment by removing dirt, grease, and other residues that can impede functionality. Regular cleaning of machinery is vital to prevent breakdowns and ensure smooth operations, particularly in industries where equipment is subjected to harsh conditions. Cleaning nozzles are engineered to deliver high-impact cleaning, reaching difficult-to-access areas and ensuring thorough sanitation. The versatility of these nozzles allows them to be used in a wide range of machinery cleaning applications, from small components to large industrial systems. The demand for cleaning nozzles in these areas is driven by the need for reliable and efficient cleaning solutions that can adapt to various industrial requirements. As industries continue to prioritize cleanliness and operational efficiency, the market for industrial tank and equipment cleaning nozzles is expected to grow, with innovations focusing on improving cleaning performance, durability, and ease of use.

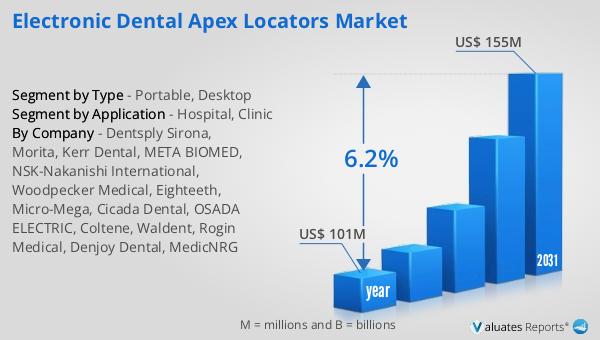

Global Industrial Tank and Equipment Cleaning Nozzle Market Outlook:

In 2024, the global market for Industrial Tank and Equipment Cleaning Nozzle was valued at $1.5 billion. By 2031, it is anticipated to expand to a revised valuation of $2.161 billion, reflecting a compound annual growth rate (CAGR) of 6.2% over the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable cleaning solutions across various industries. The market's expansion is driven by several factors, including the rising emphasis on maintaining hygiene and operational efficiency, particularly in sectors such as food and beverage, pharmaceuticals, and chemicals. As industries continue to prioritize cleanliness and compliance with stringent regulatory standards, the need for advanced cleaning nozzles that offer superior performance and ease of use is expected to rise. The market is characterized by a mix of established players and emerging companies, all striving to offer innovative solutions that cater to the diverse needs of their clients. As the market evolves, manufacturers are focusing on developing nozzles that incorporate advanced materials and technologies to enhance cleaning performance and durability. The projected growth of the market highlights the critical role that industrial tank and equipment cleaning nozzles play in ensuring the efficiency and reliability of industrial operations.

| Report Metric | Details |

| Report Name | Industrial Tank and Equipment Cleaning Nozzle Market |

| Accounted market size in year | US$ 1500 million |

| Forecasted market size in 2031 | US$ 2161 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Spraying Systems Co., Lechler, BETE, Ikeuchi, PNR Italia Srl, Spray Nozzle Engineering, Sealpump Engineering, IC Spray, Siddharth Enterprises, Guangdong BY Spraying, Hi-Tek Valve and Fitting, Guangzhou Cleaning-Spray Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |