What is Global Rubber V belt Market?

The Global Rubber V-belt Market is a significant segment within the industrial and automotive sectors, focusing on the production and distribution of V-belts made from rubber. These belts are essential components used to transmit power between axles in various machinery and vehicles. The market is driven by the demand for efficient power transmission solutions that can withstand high levels of stress and friction. Rubber V-belts are favored for their flexibility, durability, and cost-effectiveness, making them suitable for a wide range of applications. The market encompasses various types of V-belts, including wrapped and cut V-belts, each designed to meet specific operational requirements. The growth of industries such as automotive, agriculture, and manufacturing has fueled the demand for these belts, as they are integral to the functioning of machinery in these sectors. Additionally, advancements in material technology and manufacturing processes have led to the development of more robust and efficient V-belts, further propelling market growth. The global reach of this market is evident, with significant contributions from regions like Europe, North America, and Asia, where industrial activities are prominent. As industries continue to evolve, the Global Rubber V-belt Market is expected to adapt and expand, catering to the ever-changing needs of its diverse clientele.

Wrapped V-belt, Cut V-belt in the Global Rubber V belt Market:

Wrapped V-belts and Cut V-belts are two primary types of V-belts within the Global Rubber V-belt Market, each serving distinct purposes and offering unique advantages. Wrapped V-belts, also known as envelope V-belts, are characterized by their fabric-covered exterior, which provides additional protection against environmental factors such as dust, oil, and heat. This protective layer enhances the belt's durability and lifespan, making it ideal for heavy-duty applications where exposure to harsh conditions is common. Wrapped V-belts are commonly used in industrial machinery, agricultural equipment, and automotive applications, where reliability and longevity are crucial. Their design allows for smooth operation and reduced slippage, ensuring efficient power transmission even under high loads. On the other hand, Cut V-belts, also known as raw edge V-belts, are designed with a precision-cut edge that offers superior grip and flexibility. This design allows for better contact with the pulley, resulting in improved power transmission efficiency. Cut V-belts are often used in applications where high-speed operation and minimal slippage are required, such as in automotive engines and high-performance machinery. The absence of a fabric cover in Cut V-belts reduces friction and heat buildup, enhancing their performance in demanding environments. Both Wrapped and Cut V-belts are integral to the Global Rubber V-belt Market, catering to diverse industrial needs and contributing to the overall growth of the market. Manufacturers continuously innovate to improve the performance and durability of these belts, incorporating advanced materials and technologies to meet the evolving demands of various sectors. The choice between Wrapped and Cut V-belts depends on specific application requirements, with factors such as load capacity, environmental conditions, and operational speed playing a crucial role in the decision-making process. As industries continue to advance, the demand for high-quality V-belts is expected to rise, driving further innovation and expansion within the Global Rubber V-belt Market.

Industrial Machinery, Agricultural, Automotive, Other in the Global Rubber V belt Market:

The Global Rubber V-belt Market finds extensive usage across various sectors, including industrial machinery, agriculture, automotive, and others, each benefiting from the unique properties of V-belts. In the industrial machinery sector, V-belts are crucial for the operation of equipment such as conveyors, compressors, and pumps. Their ability to transmit power efficiently and withstand high levels of stress makes them indispensable in manufacturing and processing industries. The durability and reliability of rubber V-belts ensure minimal downtime and maintenance, contributing to increased productivity and cost savings. In agriculture, V-belts are used in machinery like tractors, harvesters, and irrigation systems, where they play a vital role in ensuring smooth and efficient operation. The harsh conditions often encountered in agricultural settings, such as exposure to dirt, moisture, and varying temperatures, necessitate the use of robust and durable V-belts. The automotive industry also relies heavily on rubber V-belts for various applications, including engine components, air conditioning systems, and power steering. The flexibility and strength of V-belts make them ideal for use in vehicles, where they must endure constant motion and varying loads. Additionally, the development of advanced V-belt designs has led to improved fuel efficiency and reduced emissions in modern vehicles. Beyond these primary sectors, rubber V-belts are also used in other areas such as home appliances, HVAC systems, and recreational equipment, highlighting their versatility and adaptability. The continuous demand for efficient power transmission solutions across these diverse applications underscores the importance of the Global Rubber V-belt Market. As industries evolve and new technologies emerge, the market is poised to adapt and grow, meeting the changing needs of its wide-ranging customer base.

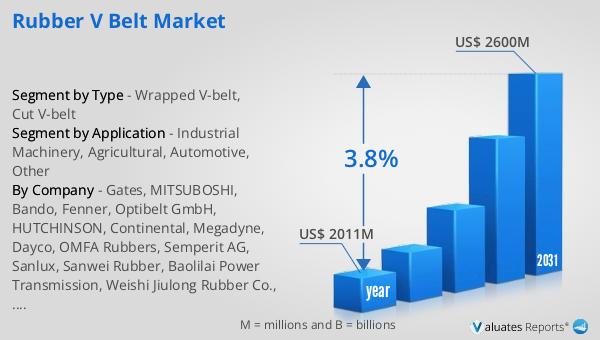

Global Rubber V belt Market Outlook:

In 2024, the global market for Rubber V-belts was valued at approximately $2,011 million, with projections indicating a growth to around $2,600 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.8% over the forecast period. The market is dominated by five major manufacturers: Gates, MITSUBOSHI, Bando, Fenner, and Sanlux Co. Ltd, which collectively account for over 53% of the market share. Among these, Gates stands out as the market leader, holding about 20% of the share. Geographically, Europe emerges as the largest market, contributing approximately 30% to the global share, followed by North America and China, with shares of about 23% and 17%, respectively. In terms of product types, Wrapped V-belts occupy the largest portion of the market, accounting for approximately 75% of the total market share. This dominance is attributed to their widespread application across various industries due to their durability and efficiency. The market dynamics are influenced by factors such as technological advancements, increasing industrialization, and the growing demand for efficient power transmission solutions. As the market continues to evolve, manufacturers are focusing on innovation and quality enhancement to maintain their competitive edge and meet the diverse needs of their global clientele.

| Report Metric | Details |

| Report Name | Rubber V belt Market |

| Accounted market size in year | US$ 2011 million |

| Forecasted market size in 2031 | US$ 2600 million |

| CAGR | 3.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gates, MITSUBOSHI, Bando, Fenner, Optibelt GmbH, HUTCHINSON, Continental, Megadyne, Dayco, OMFA Rubbers, Semperit AG, Sanlux, Sanwei Rubber, Baolilai Power Transmission, Weishi Jiulong Rubber Co., Ltd., Zhejiang Sihai Rubber Co., Ltd., Zhejiang Jinjiu Rubber Belt Co., Ltd., Zhejiang Tianji Rubber Co., Ltd., Zhejiang Powerbelt Co., Ltd., Taizhou Feilizhou Rubber-Belt Co., Ltd., Sanmen Binlong Transmission Belt Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |