What is Global Integrated Hanging Spot Welding Machine Market?

The Global Integrated Hanging Spot Welding Machine Market refers to the worldwide industry focused on the production and distribution of specialized welding machines designed for precision and efficiency. These machines are primarily used in manufacturing processes where metal parts need to be joined together with high accuracy. The term "integrated" highlights the advanced technology and automation features that these machines possess, allowing them to perform complex welding tasks with minimal human intervention. "Hanging" refers to the design of the machine, which is often suspended or mounted to allow for greater flexibility and reach during the welding process. This market is driven by the demand for high-quality welding solutions in various industries, including automotive, aerospace, and electronics. As industries continue to evolve and require more sophisticated manufacturing techniques, the demand for integrated hanging spot welding machines is expected to grow. These machines not only enhance productivity but also ensure consistent quality, making them a valuable asset in modern manufacturing environments. The market encompasses a range of products, from basic models to highly advanced systems equipped with the latest technology, catering to different industrial needs and applications.

Industrial Frequency AC, Inverter DC in the Global Integrated Hanging Spot Welding Machine Market:

In the realm of the Global Integrated Hanging Spot Welding Machine Market, two prominent technologies are Industrial Frequency AC and Inverter DC. Industrial Frequency AC spot welding machines operate using alternating current at the standard industrial frequency, typically 50 or 60 Hz. These machines are known for their robustness and simplicity, making them a popular choice in industries where durability and reliability are paramount. The AC current provides a consistent energy flow, which is crucial for achieving strong and uniform welds. These machines are often used in applications where the materials being welded are of similar thickness and composition, as the consistent energy flow helps in maintaining the integrity of the weld. On the other hand, Inverter DC spot welding machines utilize direct current, which is converted from AC using an inverter. This technology allows for more precise control over the welding process, as the current can be adjusted to suit the specific requirements of the materials being welded. Inverter DC machines are particularly advantageous when working with materials of varying thicknesses or compositions, as they offer greater flexibility in terms of energy output. The inverter technology also makes these machines more energy-efficient, as they can deliver the required power with less energy consumption. This efficiency is particularly beneficial in large-scale manufacturing operations where energy costs can be a significant concern. Furthermore, Inverter DC machines are often lighter and more compact than their AC counterparts, making them easier to integrate into automated production lines. The choice between Industrial Frequency AC and Inverter DC machines often depends on the specific needs of the manufacturing process. For instance, industries that require high-volume production with consistent quality may opt for AC machines due to their reliability and ease of maintenance. In contrast, industries that deal with a wide variety of materials and require precise control over the welding process may prefer Inverter DC machines for their versatility and efficiency. Both technologies have their unique advantages and are integral to the Global Integrated Hanging Spot Welding Machine Market, catering to the diverse needs of modern manufacturing industries. As technology continues to advance, we can expect further innovations in both AC and DC welding machines, enhancing their capabilities and expanding their applications in various industrial sectors.

Automotive, Hardware, Home Appliances, Aerospace, Military Industry, Mechanical Equipment, Others in the Global Integrated Hanging Spot Welding Machine Market:

The Global Integrated Hanging Spot Welding Machine Market finds extensive usage across several key industries, each benefiting from the unique capabilities of these advanced welding machines. In the automotive industry, these machines are indispensable for assembling vehicle bodies, frames, and other components. The precision and efficiency of integrated hanging spot welding machines ensure that automotive manufacturers can produce vehicles with high structural integrity and safety standards. In the hardware industry, these machines are used to join metal parts in the production of tools, fasteners, and other hardware products. The ability to perform precise welds quickly and consistently makes these machines ideal for high-volume production environments. Home appliances, such as refrigerators, washing machines, and ovens, also rely on spot welding machines for assembling metal components. The use of integrated hanging spot welding machines in this sector ensures that appliances are durable and reliable, meeting the high standards expected by consumers. In the aerospace industry, where precision and quality are paramount, these machines are used to join critical components of aircraft and spacecraft. The advanced technology of integrated hanging spot welding machines allows for the production of lightweight yet strong structures, essential for the performance and safety of aerospace vehicles. The military industry also benefits from the capabilities of these machines, using them to manufacture equipment and vehicles that require high-strength welds to withstand demanding conditions. In the field of mechanical equipment, these machines are used to assemble machinery and equipment that require robust and reliable welds. The versatility of integrated hanging spot welding machines makes them suitable for a wide range of applications in this sector. Additionally, other industries, such as electronics and construction, also utilize these machines for various welding tasks, benefiting from their precision and efficiency. Overall, the Global Integrated Hanging Spot Welding Machine Market plays a crucial role in modern manufacturing, providing industries with the tools they need to produce high-quality products efficiently and effectively.

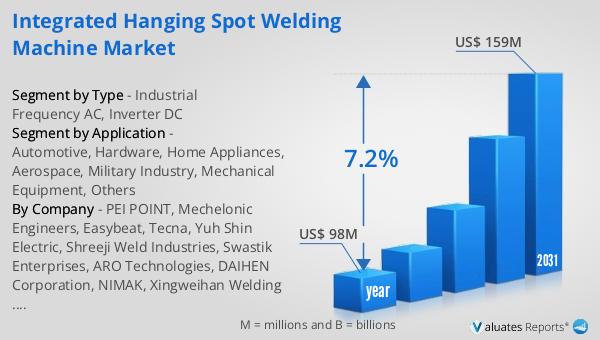

Global Integrated Hanging Spot Welding Machine Market Outlook:

In 2024, the global market for Integrated Hanging Spot Welding Machines was valued at approximately 98 million USD. This figure highlights the significant demand and reliance on these machines across various industries. As we look towards the future, projections indicate that by 2031, the market is expected to grow substantially, reaching an estimated value of 159 million USD. This growth trajectory represents a compound annual growth rate (CAGR) of 7.2% over the forecast period. Such a robust growth rate underscores the increasing adoption of integrated hanging spot welding machines as industries continue to seek efficient and reliable welding solutions. The anticipated expansion of the market can be attributed to several factors, including technological advancements, the rising demand for high-quality manufacturing processes, and the need for automation in production lines. As industries evolve and face new challenges, the role of integrated hanging spot welding machines becomes even more critical, driving further investment and innovation in this sector. The projected growth of the market not only reflects the current demand but also highlights the potential for future developments and applications of these machines in various industrial settings. As a result, stakeholders in the Global Integrated Hanging Spot Welding Machine Market can look forward to a promising future, characterized by continued growth and innovation.

| Report Metric | Details |

| Report Name | Integrated Hanging Spot Welding Machine Market |

| Accounted market size in year | US$ 98 million |

| Forecasted market size in 2031 | US$ 159 million |

| CAGR | 7.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PEI POINT, Mechelonic Engineers, Easybeat, Tecna, Yuh Shin Electric, Shreeji Weld Industries, Swastik Enterprises, ARO Technologies, DAIHEN Corporation, NIMAK, Xingweihan Welding Equipment, Tinke Automation Welding Equipment, Haojing Electromechanical, Zhengyang Welding, TIANJIN 707 HI-TEGH, Hwashi Technology, Zhenan Welding Gun Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |