What is Global Pipeline Non-metallic Expansion Joint Market?

The Global Pipeline Non-metallic Expansion Joint Market is a specialized segment within the broader industrial and construction sectors, focusing on the production and application of expansion joints made from non-metallic materials. These joints are crucial components used in pipelines to accommodate thermal expansion, contraction, and other movements, thereby preventing damage and maintaining the integrity of the pipeline systems. Unlike their metallic counterparts, non-metallic expansion joints offer advantages such as corrosion resistance, flexibility, and reduced weight, making them suitable for a variety of applications across different industries. The market encompasses a range of materials, including rubber and composite materials, each offering unique properties tailored to specific operational requirements. As industries continue to expand and modernize their infrastructure, the demand for reliable and efficient pipeline systems is on the rise, driving the growth of the non-metallic expansion joint market. This market is characterized by continuous innovation, with manufacturers striving to enhance the performance and durability of their products to meet the evolving needs of end-users. The global reach of this market underscores its importance in supporting critical infrastructure projects worldwide, ensuring the safe and efficient transport of fluids and gases.

Chloroprene Rubber, Nitrile Rubber, Fluororubber, Other in the Global Pipeline Non-metallic Expansion Joint Market:

Chloroprene Rubber, Nitrile Rubber, Fluororubber, and other materials play a significant role in the Global Pipeline Non-metallic Expansion Joint Market, each offering distinct properties that cater to various industrial needs. Chloroprene Rubber, also known as Neoprene, is valued for its excellent balance of properties, including good chemical stability, flexibility, and resistance to weathering and ozone. This makes it a preferred choice for applications where environmental factors are a concern. Chloroprene Rubber is often used in expansion joints that require durability and resilience in harsh conditions, such as in outdoor or industrial environments. On the other hand, Nitrile Rubber, or Buna-N, is renowned for its exceptional resistance to oils, fuels, and other chemicals, making it ideal for applications in the oil and gas industry. Its ability to withstand a wide range of temperatures further enhances its suitability for demanding pipeline systems that transport petroleum-based products. Fluororubber, commonly known as Viton, offers superior resistance to high temperatures and aggressive chemicals, making it indispensable in environments where extreme conditions are prevalent. This material is often used in expansion joints that are exposed to high heat or corrosive substances, ensuring long-term performance and reliability. Beyond these specific types of rubber, the market also includes other non-metallic materials such as EPDM (Ethylene Propylene Diene Monomer) and silicone, each providing unique advantages. EPDM is particularly noted for its excellent resistance to weathering, UV rays, and ozone, making it suitable for outdoor applications. Silicone, with its high thermal stability and flexibility, is often used in applications that require a wide temperature range. The diversity of materials available in the Global Pipeline Non-metallic Expansion Joint Market allows for tailored solutions that meet the specific demands of different industries, ensuring that pipeline systems operate efficiently and safely. As industries continue to evolve, the development and application of these materials remain a focal point, driving innovation and enhancing the capabilities of non-metallic expansion joints.

Municipal and Building Water Supply and Drainage, Municipal Sewage, Municipal Gas, Municipal Heating, Industrial, Other in the Global Pipeline Non-metallic Expansion Joint Market:

The usage of Global Pipeline Non-metallic Expansion Joint Market spans various sectors, each with unique requirements and challenges. In the realm of Municipal and Building Water Supply and Drainage, these expansion joints are essential for accommodating the thermal expansion and contraction of pipelines, preventing leaks and ensuring the integrity of water distribution systems. Their flexibility and resistance to corrosion make them ideal for use in environments where water quality and system reliability are paramount. In Municipal Sewage systems, non-metallic expansion joints play a crucial role in managing the movement and vibration of pipelines, which can be caused by changes in temperature or pressure. Their ability to withstand harsh chemicals and abrasive materials commonly found in sewage further underscores their importance in maintaining the efficiency and longevity of these systems. Similarly, in Municipal Gas applications, these joints are vital for ensuring the safe and efficient transport of gas through pipelines. Their non-metallic nature provides an added layer of safety by reducing the risk of sparks or corrosion, which can be critical in preventing gas leaks or explosions. In Municipal Heating systems, non-metallic expansion joints help manage the thermal expansion of pipelines that transport hot water or steam, ensuring consistent and reliable heating services. The industrial sector also benefits significantly from the use of non-metallic expansion joints, particularly in applications involving the transport of chemicals, oils, and other hazardous materials. Their resistance to a wide range of chemicals and temperatures makes them indispensable in maintaining the safety and efficiency of industrial processes. Beyond these specific applications, non-metallic expansion joints are also used in other areas such as power generation, marine, and aerospace, where their unique properties provide solutions to complex engineering challenges. The versatility and adaptability of non-metallic expansion joints make them a critical component in modern infrastructure, supporting the safe and efficient operation of various systems across multiple industries.

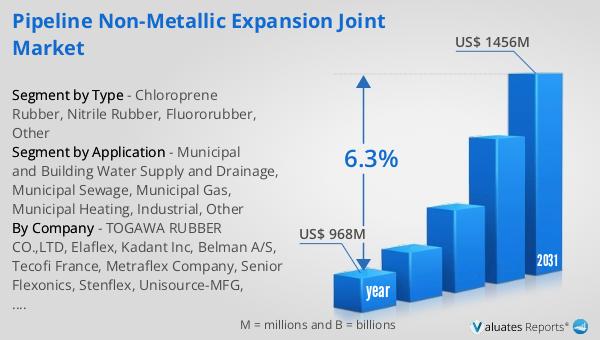

Global Pipeline Non-metallic Expansion Joint Market Outlook:

The global market for Pipeline Non-metallic Expansion Joints was valued at approximately $968 million in 2024, with projections indicating a growth trajectory that will see it reach around $1,456 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.3% over the forecast period. This upward trend reflects the increasing demand for reliable and efficient pipeline systems across various industries, driven by the need for infrastructure modernization and expansion. The market's growth is supported by the unique advantages offered by non-metallic expansion joints, such as their flexibility, corrosion resistance, and ability to accommodate thermal movements. These features make them an attractive choice for industries looking to enhance the performance and longevity of their pipeline systems. As industries continue to evolve and face new challenges, the demand for innovative solutions like non-metallic expansion joints is likely to remain strong, supporting the market's growth and development. The projected increase in market size underscores the importance of these components in supporting critical infrastructure projects worldwide, ensuring the safe and efficient transport of fluids and gases.

| Report Metric | Details |

| Report Name | Pipeline Non-metallic Expansion Joint Market |

| Accounted market size in year | US$ 968 million |

| Forecasted market size in 2031 | US$ 1456 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | TOGAWA RUBBER CO.,LTD, Elaflex, Kadant Inc, Belman A/S, Tecofi France, Metraflex Company, Senior Flexonics, Stenflex, Unisource-MFG, Mercer Rubber Co./Mason Industries, MACOGA, Flexicraft Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |