What is Global Tungsten Carbide Market?

The Global Tungsten Carbide Market is a significant segment within the materials industry, known for its exceptional hardness and resistance to wear and tear. Tungsten carbide is a compound composed of tungsten and carbon atoms, and it is renowned for its robustness, making it an ideal material for various industrial applications. This market encompasses a wide range of products, including cutting tools, wear parts, and mining tools, among others. The demand for tungsten carbide is driven by its extensive use in industries such as automotive, aerospace, mining, and construction, where durability and performance are critical. The market is characterized by continuous innovation and development, with manufacturers focusing on enhancing the properties of tungsten carbide to meet the evolving needs of end-users. Additionally, the market is influenced by factors such as technological advancements, economic conditions, and environmental regulations. As industries continue to seek materials that offer superior performance and longevity, the Global Tungsten Carbide Market is poised for growth, driven by its unique properties and versatile applications.

Grain Sizes Up to 1 µm, Grain Sizes 1-10 µm, Grain Sizes Above 10 µm, Others in the Global Tungsten Carbide Market:

In the Global Tungsten Carbide Market, grain size plays a crucial role in determining the properties and applications of tungsten carbide products. Grain sizes can be categorized into three main groups: up to 1 µm, 1-10 µm, and above 10 µm, each offering distinct characteristics and uses. Grain sizes up to 1 µm are typically used in applications requiring high hardness and wear resistance. These fine-grained carbides are ideal for precision tools and components where sharpness and durability are paramount. The smaller grain size allows for a smoother finish and greater edge retention, making them suitable for high-precision cutting tools and wear parts. On the other hand, grain sizes ranging from 1-10 µm are the most common in the market, accounting for a significant share of tungsten carbide products. These medium-grained carbides strike a balance between hardness and toughness, making them versatile for a wide range of applications. They are commonly used in cutting tools, mining tools, and wear-resistant components, where both durability and performance are essential. The larger grain sizes, above 10 µm, are typically used in applications where toughness is more critical than hardness. These coarse-grained carbides are often employed in heavy-duty applications such as mining and construction, where impact resistance and structural integrity are crucial. The larger grains provide enhanced toughness, reducing the risk of chipping and cracking under high-stress conditions. Additionally, the Global Tungsten Carbide Market also includes other specialized grain sizes tailored for specific applications. These may include ultra-fine grains for micro-machining and specialized coatings for enhanced performance. The choice of grain size is influenced by factors such as the intended application, operating conditions, and desired properties of the final product. Manufacturers in the tungsten carbide market continuously explore new grain size formulations to optimize performance and meet the diverse needs of their customers. As industries evolve and demand more advanced materials, the role of grain size in the Global Tungsten Carbide Market will continue to be a key factor in determining the success and applicability of tungsten carbide products.

Machine Tools and Components, Cutting Tools, Dies and Punches, Others in the Global Tungsten Carbide Market:

The Global Tungsten Carbide Market finds extensive usage in various areas, including machine tools and components, cutting tools, dies and punches, and other specialized applications. In the realm of machine tools and components, tungsten carbide is highly valued for its exceptional hardness and wear resistance. It is commonly used in the manufacturing of machine tool components such as inserts, tips, and wear parts, where durability and precision are critical. The ability of tungsten carbide to withstand high temperatures and maintain its hardness makes it an ideal choice for demanding machining operations. In the area of cutting tools, tungsten carbide is a preferred material due to its superior cutting performance and longevity. It is widely used in the production of drills, end mills, and saw blades, where sharpness and edge retention are essential. The high hardness of tungsten carbide allows for efficient material removal and extended tool life, reducing the need for frequent replacements and downtime. Dies and punches are another significant application area for tungsten carbide. The material's toughness and resistance to deformation make it suitable for forming and shaping operations in industries such as automotive, aerospace, and electronics. Tungsten carbide dies and punches offer excellent dimensional stability and can withstand high-pressure conditions, ensuring consistent and precise results. Beyond these primary applications, tungsten carbide is also used in various other specialized areas. It is employed in the production of wear-resistant coatings, mining tools, and surgical instruments, among others. The versatility of tungsten carbide, combined with its unique properties, makes it a valuable material across diverse industries. As technology advances and industries seek materials that offer enhanced performance and efficiency, the usage of tungsten carbide in these areas is expected to grow, driven by its ability to meet the demanding requirements of modern manufacturing and engineering processes.

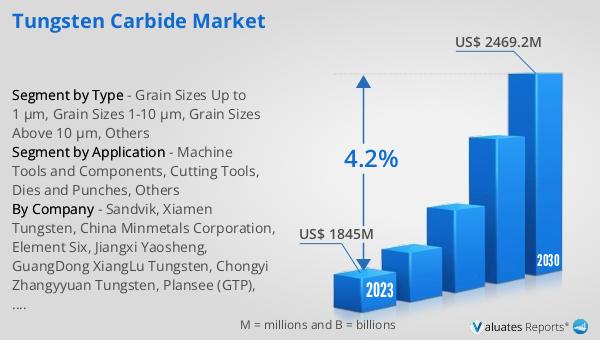

Global Tungsten Carbide Market Outlook:

The global market for tungsten carbide was valued at approximately $2,002 million in 2024, with projections indicating that it will reach an estimated size of $2,659 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.2% over the forecast period. The market is characterized by a competitive landscape, with the top three players holding around 34% of the total market share. Among the various types of tungsten carbide products, those with grain sizes ranging from 1 to 10 µm dominate the market, accounting for about 45% of the total share. This particular grain size is favored due to its balanced properties, offering a combination of hardness and toughness that is suitable for a wide range of applications. The demand for tungsten carbide products is driven by their extensive use in industries such as automotive, aerospace, mining, and construction, where durability and performance are critical. As the market continues to evolve, manufacturers are focusing on innovation and development to enhance the properties of tungsten carbide and meet the diverse needs of end-users. The growth of the Global Tungsten Carbide Market is supported by factors such as technological advancements, economic conditions, and environmental regulations, which influence the demand and supply dynamics of tungsten carbide products.

| Report Metric | Details |

| Report Name | Tungsten Carbide Market |

| Accounted market size in year | US$ 2002 million |

| Forecasted market size in 2031 | US$ 2659 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sandvik, Xiamen Tungsten, China Minmetals Corporation, Element Six, Jiangxi Yaosheng, GuangDong XiangLu Tungsten, Chongyi Zhangyyuan Tungsten, Plansee (GTP), JXTC, Japan New Metals, AST (India), Kohsei Co Ltd, ALMT Corp, Kennametal, H.C.Starck, TaeguTec Ltd, Wolfram Company JSC (Russia), Buffalo Tungsten, Eurotungstene, Lineage Alloys |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |