What is Global Pellicles for EUV Reticles Market?

The Global Pellicles for EUV Reticles Market is a specialized segment within the semiconductor industry, focusing on the production and application of pellicles used in extreme ultraviolet (EUV) lithography. EUV lithography is a cutting-edge technology employed in the manufacturing of semiconductors, enabling the creation of smaller and more efficient microchips. Pellicles are thin, transparent membranes placed over photomasks (reticles) to protect them from contamination during the lithography process. This protection is crucial as even the smallest particle can cause defects in the microchips, leading to significant losses in yield and performance. The market for these pellicles is driven by the increasing demand for advanced semiconductors in various applications, including consumer electronics, automotive, and telecommunications. As the semiconductor industry continues to push the boundaries of miniaturization and performance, the role of pellicles becomes even more critical, ensuring the integrity and efficiency of the EUV lithography process. The market is characterized by ongoing research and development efforts aimed at improving pellicle materials and designs to enhance their durability and transmission rates, thereby supporting the production of next-generation semiconductor devices.

≥90% Transmission Rate, <90% Transmission Rate in the Global Pellicles for EUV Reticles Market:

In the Global Pellicles for EUV Reticles Market, transmission rate is a key factor that determines the efficiency and effectiveness of pellicles. Transmission rate refers to the percentage of EUV light that passes through the pellicle and reaches the photomask. A higher transmission rate is generally preferred as it allows more light to reach the photomask, improving the lithography process's overall efficiency. Pellicles with a transmission rate of ≥90% are considered highly efficient, as they allow the majority of the EUV light to pass through, minimizing energy loss and enhancing the lithography process's precision. These high-transmission pellicles are particularly important in advanced semiconductor manufacturing, where even slight variations in light intensity can impact the final product's quality and performance. On the other hand, pellicles with a transmission rate of <90% are less efficient, as they allow less EUV light to pass through. While these pellicles may still be used in certain applications, they are generally less desirable for cutting-edge semiconductor manufacturing, where maximum efficiency and precision are required. The development of pellicles with higher transmission rates is a key focus area for manufacturers, as it directly impacts the performance and yield of the semiconductor manufacturing process. Companies are investing in research and development to create pellicles with improved materials and designs that can achieve higher transmission rates while maintaining durability and resistance to contamination. This ongoing innovation is crucial for meeting the semiconductor industry's evolving demands and supporting the production of increasingly complex and powerful microchips. As the Global Pellicles for EUV Reticles Market continues to grow, the emphasis on transmission rate will remain a critical factor in determining the success and competitiveness of pellicle manufacturers.

IDM, Foundry in the Global Pellicles for EUV Reticles Market:

The usage of Global Pellicles for EUV Reticles Market in Integrated Device Manufacturers (IDM) and foundries is pivotal to the advancement of semiconductor technology. IDMs are companies that design, manufacture, and sell integrated circuits (ICs) in-house, while foundries are specialized facilities that manufacture ICs for other companies. Both types of organizations rely heavily on EUV lithography to produce cutting-edge semiconductors, and pellicles play a crucial role in this process. In IDMs, pellicles are used to protect the photomasks during the EUV lithography process, ensuring that the intricate patterns required for advanced ICs are accurately transferred onto the silicon wafers. This protection is essential for maintaining high yields and minimizing defects, which can significantly impact the performance and reliability of the final products. By using high-quality pellicles with optimal transmission rates, IDMs can enhance their manufacturing processes, reduce costs, and improve the overall quality of their ICs. In foundries, the use of pellicles is equally important, as these facilities often handle high-volume production for multiple clients. The ability to produce defect-free semiconductors efficiently is a key competitive advantage for foundries, and pellicles are an integral part of achieving this goal. By investing in advanced pellicles with high transmission rates and durability, foundries can ensure that their lithography processes are as efficient and precise as possible, meeting the stringent demands of their clients. The Global Pellicles for EUV Reticles Market is thus a critical component of the semiconductor supply chain, supporting both IDMs and foundries in their efforts to produce the next generation of semiconductor devices. As the demand for more powerful and efficient semiconductors continues to grow, the importance of pellicles in the manufacturing process will only increase, driving further innovation and development in this specialized market.

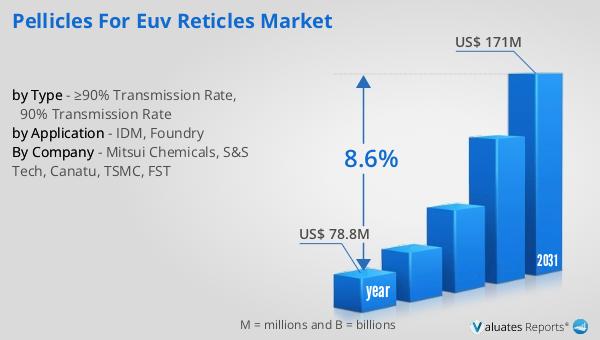

Global Pellicles for EUV Reticles Market Outlook:

The worldwide market for Pellicles for EUV Reticles was estimated to be worth $78.8 million in 2024, with expectations to expand to a revised valuation of $171 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.6% over the forecast period. In 2021, a notable development came from the South Korean company SS Tech, which successfully developed a pellicle boasting a transmittance rate exceeding 90%. This advancement underscores the ongoing efforts within the industry to enhance pellicle performance, particularly in terms of transmission rates, which are crucial for optimizing the EUV lithography process. The ability to achieve such high transmittance is a significant milestone, as it directly impacts the efficiency and precision of semiconductor manufacturing. As the market continues to evolve, innovations like those from SS Tech are expected to play a pivotal role in shaping the future of pellicle technology, supporting the production of increasingly sophisticated and powerful semiconductor devices. The growth trajectory of the Global Pellicles for EUV Reticles Market highlights the critical importance of these components in the semiconductor industry, as they enable the production of smaller, faster, and more efficient microchips that power a wide range of modern technologies.

| Report Metric | Details |

| Report Name | Pellicles for EUV Reticles Market |

| Accounted market size in year | US$ 78.8 million |

| Forecasted market size in 2031 | US$ 171 million |

| CAGR | 8.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mitsui Chemicals, S&S Tech, Canatu, TSMC, FST |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |