What is Global Real-Time Traffic Data Market?

The Global Real-Time Traffic Data Market refers to the industry that provides up-to-the-minute information on traffic conditions across the world. This market encompasses various technologies and services that collect, analyze, and disseminate data about traffic flow, congestion, accidents, and other road conditions in real-time. The data is gathered from multiple sources, including GPS devices, road sensors, cameras, and mobile applications. This information is then processed and made available to users through various platforms such as navigation systems, traffic management centers, and mobile apps. The primary goal of the Global Real-Time Traffic Data Market is to enhance road safety, reduce travel time, and improve overall traffic management. By providing accurate and timely traffic information, this market helps drivers make informed decisions, avoid congested routes, and reach their destinations more efficiently. Additionally, it supports government agencies and businesses in optimizing their operations and planning infrastructure projects. Overall, the Global Real-Time Traffic Data Market plays a crucial role in modern transportation systems by leveraging advanced technologies to deliver valuable insights and improve the overall driving experience.

Traffic Data, Mobility Data, Car Traffic Data in the Global Real-Time Traffic Data Market:

Traffic data refers to the information collected about the movement of vehicles on roads and highways. This data includes details such as vehicle speed, traffic volume, travel time, and congestion levels. It is gathered using various methods, including road sensors, cameras, GPS devices, and mobile applications. Mobility data, on the other hand, encompasses a broader range of information related to the movement of people and goods. This includes data on public transportation usage, pedestrian movement, and the flow of goods through supply chains. Mobility data is collected from sources such as public transit systems, mobile devices, and logistics companies. Car traffic data specifically focuses on the movement of cars on roads. It includes information on vehicle speed, travel time, congestion levels, and incidents such as accidents or road closures. This data is collected using technologies such as GPS devices, road sensors, and cameras. In the context of the Global Real-Time Traffic Data Market, these different types of data are integrated and analyzed to provide a comprehensive view of traffic conditions. This information is then used to inform traffic management strategies, optimize transportation systems, and improve the overall efficiency of road networks. By leveraging advanced technologies and data analytics, the Global Real-Time Traffic Data Market helps to enhance road safety, reduce travel time, and improve the overall driving experience.

Government, Logistics, Infrastructure Construction, Automobile, Other in the Global Real-Time Traffic Data Market:

The Global Real-Time Traffic Data Market has a wide range of applications across various sectors, including government, logistics, infrastructure construction, automobile, and others. In the government sector, real-time traffic data is used to manage and monitor traffic flow, reduce congestion, and improve road safety. Traffic management centers use this data to make informed decisions about traffic signal timings, road closures, and incident response. Additionally, real-time traffic data is used to plan and implement infrastructure projects, such as road expansions and public transportation systems. In the logistics sector, real-time traffic data is used to optimize delivery routes, reduce travel time, and improve overall efficiency. Logistics companies use this data to monitor traffic conditions, avoid congested routes, and ensure timely deliveries. In the infrastructure construction sector, real-time traffic data is used to plan and manage construction projects, minimize disruptions, and ensure the safety of workers and road users. Construction companies use this data to monitor traffic conditions, plan detours, and coordinate with traffic management centers. In the automobile sector, real-time traffic data is used to enhance navigation systems, improve driver safety, and optimize vehicle performance. Automakers use this data to develop advanced driver assistance systems, such as adaptive cruise control and lane-keeping assist. Additionally, real-time traffic data is used to inform the development of autonomous vehicles, which rely on accurate and timely traffic information to navigate safely and efficiently. In other sectors, real-time traffic data is used to support various applications, such as urban planning, emergency response, and environmental monitoring. Overall, the Global Real-Time Traffic Data Market plays a crucial role in enhancing the efficiency and safety of transportation systems across various sectors.

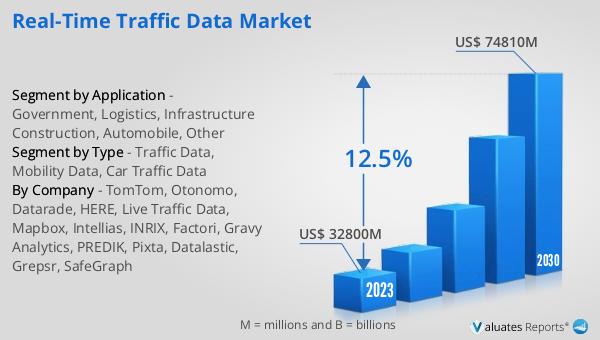

Global Real-Time Traffic Data Market Outlook:

The global Real-Time Traffic Data market was valued at US$ 32,800 million in 2023 and is anticipated to reach US$ 74,810 million by 2030, witnessing a CAGR of 12.5% during the forecast period 2024-2030. This significant growth reflects the increasing demand for accurate and timely traffic information to improve road safety, reduce travel time, and enhance overall traffic management. The market's expansion is driven by advancements in technology, such as the integration of GPS devices, road sensors, cameras, and mobile applications, which enable the collection and analysis of real-time traffic data. Additionally, the growing adoption of smart transportation systems and the increasing focus on developing sustainable and efficient transportation networks contribute to the market's growth. As more governments and businesses recognize the value of real-time traffic data in optimizing operations and planning infrastructure projects, the demand for these services is expected to continue rising. The Global Real-Time Traffic Data Market plays a crucial role in modern transportation systems by providing valuable insights that help drivers make informed decisions, avoid congested routes, and reach their destinations more efficiently. Overall, the market's growth trajectory highlights the importance of leveraging advanced technologies to deliver accurate and timely traffic information, ultimately improving the overall driving experience and supporting the development of smarter, more efficient transportation networks.

| Report Metric | Details |

| Report Name | Real-Time Traffic Data Market |

| Accounted market size in 2023 | US$ 32800 million |

| Forecasted market size in 2030 | US$ 74810 million |

| CAGR | 12.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | TomTom, Otonomo, Datarade, HERE, Live Traffic Data, Mapbox, Intellias, INRIX, Factori, Gravy Analytics, PREDIK, Pixta, Datalastic, Grepsr, SafeGraph |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |