What is Industrial Wet Laminating Machine - Global Market?

Industrial wet laminating machines are essential tools in various manufacturing sectors, designed to bond multiple layers of materials using adhesives and pressure. These machines are pivotal in industries where the durability and quality of laminated products are crucial. The global market for these machines is expanding due to the increasing demand for high-quality laminated products across different sectors. Industrial wet laminating machines are used to enhance the strength, appearance, and functionality of materials, making them suitable for packaging, automotive, aerospace, and other applications. The machines operate by applying a wet adhesive to the substrate, which is then pressed together with another layer to form a strong bond. This process is vital for producing laminated materials that require flexibility, durability, and resistance to environmental factors. The global market for industrial wet laminating machines is driven by technological advancements, increasing industrialization, and the need for efficient and cost-effective manufacturing solutions. As industries continue to evolve, the demand for these machines is expected to grow, offering opportunities for manufacturers to innovate and improve their product offerings.

100 m/min, 150 m/min, 250 m/min, Others in the Industrial Wet Laminating Machine - Global Market:

The industrial wet laminating machine market is categorized based on the speed of operation, which is a critical factor in determining the machine's efficiency and suitability for different applications. Machines with a speed of 100 m/min are typically used in smaller-scale operations or where precision is more critical than speed. These machines are ideal for industries that require careful handling of materials, such as the pharmaceutical sector, where the integrity of the laminated product is paramount. On the other hand, machines operating at 150 m/min offer a balance between speed and precision, making them suitable for medium-sized operations. These machines are often used in the food and beverage industry, where the demand for laminated packaging materials is high, and production efficiency is crucial. The 250 m/min machines are designed for large-scale operations, where speed is a priority. These machines are commonly used in the automotive and aerospace industries, where large volumes of laminated materials are required, and production timelines are tight. The ability to produce high-quality laminated products quickly is a significant advantage in these sectors, where efficiency and productivity are key. Other machines in the market may offer varying speeds and features, catering to specific industry needs and applications. These machines are designed to provide flexibility and adaptability, allowing manufacturers to customize their operations based on the specific requirements of their products and processes. The choice of machine speed is influenced by several factors, including the type of materials being laminated, the desired quality of the final product, and the production capacity of the manufacturing facility. As the global market for industrial wet laminating machines continues to grow, manufacturers are focusing on developing machines that offer enhanced speed, precision, and efficiency to meet the evolving needs of different industries. Technological advancements are playing a crucial role in this development, with innovations in machine design and operation leading to improved performance and capabilities. The demand for high-speed laminating machines is expected to increase as industries seek to enhance their production processes and reduce operational costs. This trend is driving manufacturers to invest in research and development to create machines that can operate at higher speeds without compromising on quality or reliability. The global market for industrial wet laminating machines is characterized by a diverse range of products, each designed to meet the specific needs of different industries and applications. As the market continues to evolve, manufacturers are focusing on developing machines that offer greater flexibility, efficiency, and performance to meet the changing demands of their customers.

Pharmaceutical, Food & Beverages, Automotive, Aerospace & Defense, Others in the Industrial Wet Laminating Machine - Global Market:

Industrial wet laminating machines play a crucial role in various sectors, including pharmaceuticals, food and beverages, automotive, aerospace and defense, and others. In the pharmaceutical industry, these machines are used to produce laminated packaging materials that protect sensitive products from environmental factors such as moisture, light, and air. The integrity of pharmaceutical products is paramount, and laminated packaging ensures that these products remain safe and effective throughout their shelf life. In the food and beverage industry, industrial wet laminating machines are used to create packaging materials that preserve the freshness and quality of products. Laminated packaging provides a barrier against contaminants and extends the shelf life of perishable goods, making it an essential component of the food supply chain. The automotive industry relies on industrial wet laminating machines to produce laminated materials used in vehicle interiors and exteriors. These materials enhance the durability and aesthetic appeal of vehicles, providing protection against wear and tear and improving the overall quality of the finished product. In the aerospace and defense sectors, laminated materials are used to produce lightweight and durable components that meet stringent safety and performance standards. Industrial wet laminating machines are essential for manufacturing these high-performance materials, which are critical to the success of aerospace and defense applications. Other industries, such as construction and electronics, also benefit from the use of industrial wet laminating machines. In construction, laminated materials are used to produce durable and weather-resistant building components, while in electronics, they are used to create protective coatings for sensitive devices. The versatility and efficiency of industrial wet laminating machines make them indispensable tools in these industries, where quality and performance are paramount. As the global market for industrial wet laminating machines continues to grow, manufacturers are focusing on developing machines that offer enhanced capabilities and performance to meet the evolving needs of different sectors. Technological advancements are driving innovation in machine design and operation, leading to improved efficiency, precision, and reliability. The demand for high-quality laminated products is expected to increase as industries seek to enhance their production processes and reduce operational costs. This trend is driving manufacturers to invest in research and development to create machines that can meet the specific needs of their customers and provide a competitive edge in the global market.

Industrial Wet Laminating Machine - Global Market Outlook:

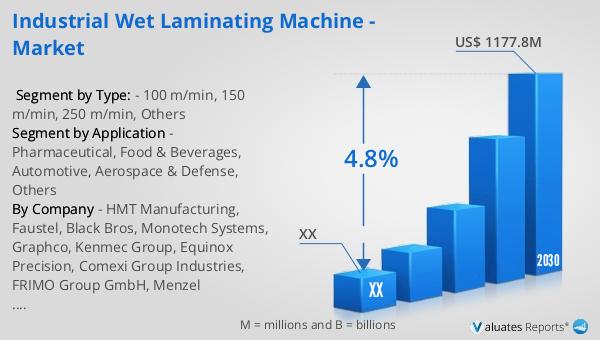

The global market for industrial wet laminating machines was valued at approximately $847 million in 2023, with projections indicating a growth to around $1,177.8 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.8% over the forecast period from 2024 to 2030. The North American segment of this market was valued at a certain amount in 2023, with expectations of reaching a higher value by 2030, although specific figures for this region were not provided. The anticipated growth in the market is driven by increasing demand across various industries, including automotive, aerospace, and packaging, where laminated materials are essential for product quality and durability. The market's expansion is also supported by technological advancements in laminating machine design and operation, which enhance efficiency and productivity. As industries continue to evolve and seek cost-effective manufacturing solutions, the demand for industrial wet laminating machines is expected to rise, offering opportunities for manufacturers to innovate and improve their product offerings. The growth in the market reflects the increasing importance of laminated materials in various applications and the need for efficient and reliable manufacturing processes.

| Report Metric | Details |

| Report Name | Industrial Wet Laminating Machine - Market |

| Forecasted market size in 2030 | US$ 1177.8 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | HMT Manufacturing, Faustel, Black Bros, Monotech Systems, Graphco, Kenmec Group, Equinox Precision, Comexi Group Industries, FRIMO Group GmbH, Menzel Maschinenbau |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |