What is Lithium Battery Cell Testing Equipment - Global Market?

Lithium battery cell testing equipment is a crucial component in the global market, primarily used to ensure the safety, efficiency, and longevity of lithium batteries. These batteries are integral to a wide range of applications, from powering electric vehicles to storing renewable energy and running consumer electronics. The testing equipment is designed to evaluate various parameters of lithium battery cells, such as capacity, voltage, current, and temperature, under different conditions. This ensures that the batteries meet the required standards and specifications before they are deployed in real-world applications. The global market for this equipment is driven by the increasing demand for lithium batteries, fueled by the rise in electric vehicles, renewable energy storage solutions, and portable electronic devices. As technology advances, the need for more sophisticated and precise testing equipment grows, pushing manufacturers to innovate and improve their offerings. This market is characterized by a mix of established players and new entrants, all striving to provide reliable and efficient testing solutions to meet the evolving needs of the battery industry. The growth of this market is also supported by stringent regulations and standards that mandate rigorous testing of battery cells to ensure safety and performance.

Power Battery, Energy Storage Battery, 3C Battery in the Lithium Battery Cell Testing Equipment - Global Market:

Power batteries, energy storage batteries, and 3C (computer, communication, and consumer electronics) batteries are three primary categories within the lithium battery cell testing equipment market. Power batteries are predominantly used in electric vehicles (EVs) and are critical for the transition to sustainable transportation. These batteries require rigorous testing to ensure they can deliver high power output and withstand the demanding conditions of automotive applications. Testing equipment for power batteries focuses on evaluating their capacity, cycle life, thermal stability, and safety features. As the demand for EVs continues to rise, the need for reliable testing equipment becomes even more crucial to ensure the safety and efficiency of these batteries. Energy storage batteries, on the other hand, are used to store energy from renewable sources like solar and wind. These batteries play a vital role in balancing supply and demand in the energy grid and require testing equipment that can assess their long-term performance, efficiency, and safety. The testing process for energy storage batteries involves simulating various environmental conditions to ensure they can operate effectively over extended periods. This is essential for maintaining the reliability and stability of the energy grid. 3C batteries are used in a wide range of consumer electronics, including smartphones, laptops, and tablets. These batteries need to be compact, lightweight, and capable of delivering consistent performance. Testing equipment for 3C batteries focuses on evaluating their capacity, charge and discharge rates, and safety features. As consumer electronics become more advanced and power-hungry, the demand for high-quality testing equipment increases to ensure these batteries can meet the performance expectations of end-users. The global market for lithium battery cell testing equipment is driven by the growing demand for these three types of batteries, each with its unique testing requirements. Manufacturers of testing equipment are continually innovating to develop solutions that can accurately assess the performance and safety of power, energy storage, and 3C batteries. This involves the integration of advanced technologies such as artificial intelligence and machine learning to enhance the precision and efficiency of testing processes. Additionally, the market is influenced by regulatory standards that mandate comprehensive testing of lithium batteries to ensure they meet safety and performance criteria. As the adoption of electric vehicles, renewable energy solutions, and consumer electronics continues to grow, the demand for lithium battery cell testing equipment is expected to increase, driving further innovation and development in this market.

Cell Manufacturer, Laboratory, Others in the Lithium Battery Cell Testing Equipment - Global Market:

Lithium battery cell testing equipment is utilized in various sectors, including cell manufacturers, laboratories, and other industries, each with specific requirements and applications. For cell manufacturers, this equipment is essential for quality control and assurance during the production process. Manufacturers use testing equipment to evaluate the performance and safety of battery cells before they are assembled into battery packs. This involves testing for capacity, voltage, internal resistance, and thermal stability to ensure that each cell meets the required specifications. By identifying and addressing any issues early in the production process, manufacturers can reduce the risk of defects and improve the overall quality of their products. In laboratories, lithium battery cell testing equipment is used for research and development purposes. Researchers use this equipment to study the behavior of battery cells under various conditions and to develop new materials and technologies that can enhance battery performance. This involves conducting experiments to test the effects of different temperatures, charge and discharge rates, and other variables on battery performance. The insights gained from these experiments can lead to the development of more efficient and reliable batteries, driving innovation in the battery industry. Other industries, such as automotive, aerospace, and consumer electronics, also rely on lithium battery cell testing equipment to ensure the safety and performance of their products. In the automotive industry, for example, testing equipment is used to evaluate the performance of batteries in electric vehicles, ensuring they can deliver the required power and range. In the aerospace industry, testing equipment is used to assess the performance of batteries used in aircraft and spacecraft, where safety and reliability are paramount. In the consumer electronics industry, testing equipment is used to ensure that batteries in devices like smartphones and laptops can deliver consistent performance and meet consumer expectations. The global market for lithium battery cell testing equipment is driven by the diverse applications of this equipment across various industries. Manufacturers of testing equipment are continually developing new solutions to meet the evolving needs of their customers, incorporating advanced technologies to enhance the accuracy and efficiency of testing processes. As the demand for lithium batteries continues to grow, driven by the increasing adoption of electric vehicles, renewable energy solutions, and consumer electronics, the market for lithium battery cell testing equipment is expected to expand, supporting the development of safer and more efficient batteries.

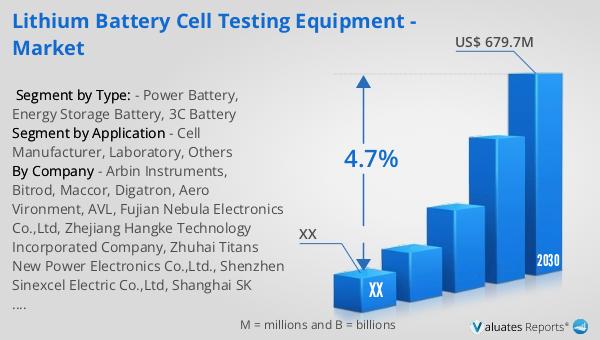

Lithium Battery Cell Testing Equipment - Global Market Outlook:

The global market for lithium battery cell testing equipment was valued at approximately $495 million in 2023 and is projected to grow to around $679.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.7% during the forecast period from 2024 to 2030. This growth is largely driven by the increasing demand for lithium-ion batteries, particularly in China, where government policies heavily focus on promoting new energy vehicles and lithium-ion battery production. In 2022, China's new energy vehicle sales reached 6.8 million units, accounting for 63.6% of the global market share. This significant market penetration highlights China's leadership in the adoption of electric vehicles, compared to Europe and North America, where penetration rates were 19% and 6%, respectively. According to the Ministry of Industry and Information Technology, China's lithium-ion battery production reached 750 GWh in 2022, marking an impressive year-on-year increase of over 130%. This rapid growth in production capacity underscores the country's commitment to advancing its battery manufacturing capabilities and supporting the global transition to sustainable energy solutions. As the demand for lithium batteries continues to rise, the market for testing equipment is expected to expand, driven by the need for reliable and efficient testing solutions to ensure the safety and performance of these batteries.

| Report Metric | Details |

| Report Name | Lithium Battery Cell Testing Equipment - Market |

| Forecasted market size in 2030 | US$ 679.7 million |

| CAGR | 4.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Arbin Instruments, Bitrod, Maccor, Digatron, Aero Vironment, AVL, Fujian Nebula Electronics Co.,Ltd, Zhejiang Hangke Technology Incorporated Company, Zhuhai Titans New Power Electronics Co.,Ltd., Shenzhen Sinexcel Electric Co.,Ltd, Shanghai SK Automation Technology Co.,Ltd, Hubei Techpow Electric Co., Ltd, Repower Technology Co.,Ltd, Shenzhen HYNN Technologies Co., Ltd., Neware Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |