What is Basket Blasting Machine - Global Market?

Basket blasting machines are specialized equipment used in various industries to clean, polish, or prepare surfaces by blasting them with abrasive materials. These machines are designed to handle multiple small parts simultaneously, making them highly efficient for batch processing. The global market for basket blasting machines is witnessing significant growth due to the increasing demand for efficient and cost-effective surface treatment solutions. These machines are particularly popular in industries such as automotive, aerospace, and manufacturing, where precision and surface quality are paramount. The versatility of basket blasting machines allows them to be used for a wide range of applications, from removing rust and paint to preparing surfaces for coating or bonding. As industries continue to seek ways to improve productivity and reduce operational costs, the demand for advanced surface treatment technologies like basket blasting machines is expected to rise. The market is characterized by a mix of established players and new entrants, all vying to offer innovative solutions that meet the evolving needs of their customers. With advancements in technology and increasing awareness about the benefits of automated surface treatment processes, the global market for basket blasting machines is poised for steady growth in the coming years.

Automatic, Manual, Others in the Basket Blasting Machine - Global Market:

Basket blasting machines can be categorized into three main types based on their operation: automatic, manual, and others. Automatic basket blasting machines are equipped with advanced features that allow for fully automated operation, minimizing the need for human intervention. These machines are ideal for large-scale production environments where consistency and efficiency are crucial. They are designed to handle high volumes of parts with precision, ensuring uniform surface treatment across all components. The automation in these machines often includes programmable controls, robotic arms, and conveyor systems that facilitate seamless operation. This not only enhances productivity but also reduces the risk of human error, leading to better quality outcomes. On the other hand, manual basket blasting machines require human operators to control the blasting process. These machines are typically used in smaller operations or for specialized tasks where a high degree of control and customization is needed. Operators can adjust the blasting parameters in real-time, allowing for greater flexibility in handling different types of materials and surface conditions. While manual machines may not offer the same level of efficiency as their automated counterparts, they provide the advantage of adaptability and are often more cost-effective for small to medium-sized enterprises. The "others" category includes semi-automatic machines and hybrid models that combine elements of both manual and automatic systems. These machines offer a balance between automation and manual control, providing users with the flexibility to switch between modes as needed. Semi-automatic machines are particularly useful in situations where certain tasks can be automated, but human oversight is still required for quality assurance or handling complex parts. Hybrid models, on the other hand, are designed to offer the best of both worlds, allowing operators to take advantage of automation while retaining the ability to intervene manually when necessary. This versatility makes them suitable for a wide range of applications and industries. As the global market for basket blasting machines continues to evolve, manufacturers are focusing on developing innovative solutions that cater to the diverse needs of their customers. This includes incorporating advanced technologies such as IoT and AI to enhance machine performance and provide real-time monitoring and diagnostics. By offering a variety of options, from fully automated systems to manual and hybrid models, the market is well-positioned to meet the growing demand for efficient and adaptable surface treatment solutions.

Chemical Industry, Architecture, Others in the Basket Blasting Machine - Global Market:

Basket blasting machines are widely used in various industries, including the chemical industry, architecture, and others, due to their ability to efficiently clean and prepare surfaces. In the chemical industry, these machines play a crucial role in maintaining equipment and facilities. They are used to remove residues, rust, and other contaminants from tanks, pipes, and other equipment, ensuring that they operate efficiently and safely. The ability to clean complex geometries and hard-to-reach areas makes basket blasting machines an invaluable tool in this sector. Additionally, they help in extending the lifespan of equipment by preventing corrosion and wear, which can lead to costly repairs or replacements. In the field of architecture, basket blasting machines are used to prepare surfaces for painting, coating, or other finishing processes. They are particularly useful in restoring old buildings or structures, where removing layers of paint, rust, or other materials is necessary to achieve a clean and smooth surface. The precision and efficiency of these machines ensure that surfaces are uniformly treated, resulting in a high-quality finish. Moreover, they can be used on a variety of materials, including metal, stone, and concrete, making them versatile tools for architectural applications. Beyond these industries, basket blasting machines find applications in numerous other sectors, such as automotive, aerospace, and manufacturing. In the automotive industry, they are used to clean and prepare parts for assembly or coating, ensuring that they meet the required quality standards. In aerospace, the machines are employed to treat components that require precise surface finishes to ensure optimal performance and safety. The manufacturing sector benefits from the use of basket blasting machines in various processes, from cleaning molds and dies to preparing surfaces for welding or bonding. The versatility and efficiency of basket blasting machines make them indispensable tools across a wide range of industries. As technology continues to advance, these machines are becoming more sophisticated, offering enhanced capabilities and improved performance. This, in turn, is driving their adoption in new areas and applications, further expanding their reach in the global market.

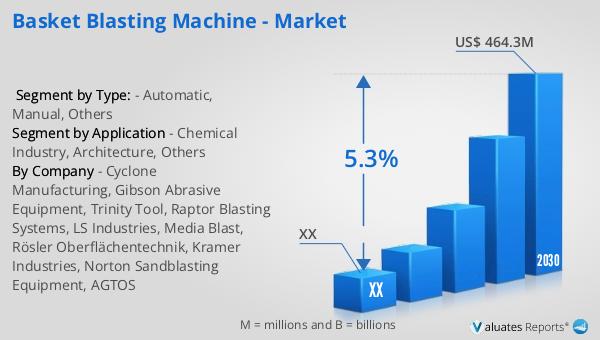

Basket Blasting Machine - Global Market Outlook:

In 2023, the global market for basket blasting machines was valued at approximately $324 million. Looking ahead, this market is projected to grow significantly, reaching an estimated value of $464.3 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 5.3% over the forecast period from 2024 to 2030. The anticipated expansion of the market can be attributed to several factors, including the increasing demand for efficient surface treatment solutions across various industries. As businesses continue to seek ways to enhance productivity and reduce operational costs, the adoption of advanced technologies like basket blasting machines is expected to rise. These machines offer numerous benefits, such as improved surface quality, reduced processing times, and lower labor costs, making them an attractive option for companies looking to optimize their operations. Furthermore, the ongoing advancements in automation and digitalization are likely to drive further innovation in the basket blasting machine market, leading to the development of more sophisticated and versatile solutions. As a result, the market is poised for steady growth, with both established players and new entrants striving to capture a share of this expanding market. The positive outlook for the basket blasting machine market underscores the growing importance of efficient surface treatment technologies in today's competitive industrial landscape.

| Report Metric | Details |

| Report Name | Basket Blasting Machine - Market |

| Forecasted market size in 2030 | US$ 464.3 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Cyclone Manufacturing, Gibson Abrasive Equipment, Trinity Tool, Raptor Blasting Systems, LS Industries, Media Blast, Rösler Oberflächentechnik, Kramer Industries, Norton Sandblasting Equipment, AGTOS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |