What is Grain Heat Pump Dryer - Global Market?

The Grain Heat Pump Dryer is a specialized piece of equipment designed to efficiently dry grains by utilizing heat pump technology. This technology is known for its energy efficiency and environmental friendliness, as it transfers heat rather than generating it directly. The global market for Grain Heat Pump Dryers is expanding due to the increasing demand for sustainable agricultural practices and the need to reduce post-harvest losses. These dryers are particularly beneficial in regions with high humidity, where traditional drying methods may not be effective. By maintaining a controlled drying environment, Grain Heat Pump Dryers help preserve the quality and nutritional value of grains, making them a valuable asset for farmers and grain processors. As the global population continues to grow, the demand for efficient grain drying solutions is expected to rise, further driving the market for these innovative dryers.

Integral Dryer, Split Dryer in the Grain Heat Pump Dryer - Global Market:

Integral and Split Dryers are two main types of Grain Heat Pump Dryers available in the global market, each offering unique advantages and applications. Integral Dryers are designed as a single, compact unit where the heat pump and drying chamber are integrated. This design is particularly advantageous for small to medium-sized operations where space is limited. The compact nature of Integral Dryers allows for easy installation and operation, making them an ideal choice for farmers and processors who need a straightforward, efficient drying solution. These dryers are often equipped with advanced control systems that allow users to precisely manage temperature and humidity levels, ensuring optimal drying conditions for various types of grains. The simplicity of the Integral Dryer design also means that maintenance is generally straightforward, with fewer components to manage and service. On the other hand, Split Dryers consist of separate units for the heat pump and the drying chamber. This configuration offers greater flexibility in terms of installation and operation, as the components can be positioned independently to suit the specific layout and requirements of a facility. Split Dryers are particularly beneficial for larger operations where the drying capacity needs to be scaled up or customized. The separation of components allows for more efficient heat distribution and air circulation, which can lead to faster drying times and improved energy efficiency. Additionally, the modular nature of Split Dryers means that they can be easily upgraded or expanded as the needs of the operation change over time. Both Integral and Split Dryers utilize the principles of heat pump technology to achieve efficient and consistent drying results. Heat pumps work by transferring heat from one area to another, using a refrigerant cycle to absorb heat from the surrounding environment and release it into the drying chamber. This process is highly energy-efficient, as it requires less energy to transfer heat than to generate it directly. As a result, Grain Heat Pump Dryers can significantly reduce energy consumption compared to traditional drying methods, leading to cost savings and a reduced environmental impact. The choice between an Integral and a Split Dryer will largely depend on the specific needs and constraints of the user. For smaller operations with limited space and straightforward drying requirements, an Integral Dryer may be the most practical and cost-effective option. In contrast, larger operations with more complex drying needs may benefit from the flexibility and scalability offered by a Split Dryer. Regardless of the type chosen, both Integral and Split Dryers provide a reliable and efficient solution for drying grains, helping to preserve their quality and extend their shelf life. As the global market for Grain Heat Pump Dryers continues to grow, advancements in technology and design are likely to further enhance the performance and appeal of these innovative drying solutions.

Cereal, Soybean, Corn, Others in the Grain Heat Pump Dryer - Global Market:

The Grain Heat Pump Dryer is a versatile tool used in the drying of various grains, including cereals, soybeans, corn, and others. In the cereal industry, these dryers play a crucial role in ensuring that grains such as wheat, rice, and barley are dried to the optimal moisture content. This is essential for preventing spoilage and maintaining the quality of the grains during storage and transportation. By using a Grain Heat Pump Dryer, cereal producers can achieve consistent drying results, which helps to preserve the nutritional value and flavor of the grains. This is particularly important in regions with high humidity, where traditional sun drying methods may not be effective or feasible. In the soybean industry, Grain Heat Pump Dryers are used to reduce the moisture content of harvested soybeans to a safe level for storage and processing. Soybeans are highly susceptible to spoilage if not dried properly, and the use of a heat pump dryer ensures that the drying process is both efficient and gentle. This helps to maintain the quality of the soybeans, which is crucial for producing high-quality soybean products such as tofu, soy milk, and soy oil. The energy efficiency of Grain Heat Pump Dryers also makes them an attractive option for soybean producers looking to reduce their operational costs and environmental impact. Corn is another major crop that benefits from the use of Grain Heat Pump Dryers. Corn must be dried to a specific moisture content to prevent mold growth and spoilage during storage. Traditional drying methods can be time-consuming and energy-intensive, but Grain Heat Pump Dryers offer a more efficient and reliable solution. By providing a controlled drying environment, these dryers help to preserve the quality and yield of the corn, which is essential for both food and industrial applications. The use of Grain Heat Pump Dryers in the corn industry is expected to increase as producers seek to improve their drying processes and reduce post-harvest losses. In addition to cereals, soybeans, and corn, Grain Heat Pump Dryers are also used for drying other types of grains and seeds, such as sunflower seeds, peanuts, and pulses. These dryers offer a flexible and efficient solution for drying a wide range of agricultural products, helping to ensure their quality and safety for consumption. As the global demand for grains and seeds continues to rise, the use of Grain Heat Pump Dryers is likely to become increasingly important in meeting the needs of the agricultural industry. By providing a reliable and energy-efficient drying solution, these dryers help to support sustainable agricultural practices and reduce the environmental impact of grain production.

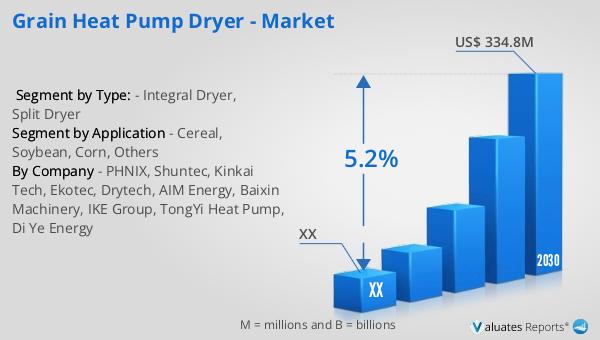

Grain Heat Pump Dryer - Global Market Outlook:

The global market for Grain Heat Pump Dryers was valued at approximately $231 million in 2023. It is projected to grow to a revised size of about $334.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.2% over the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and sustainable grain drying solutions worldwide. In North America, the market for Grain Heat Pump Dryers was also valued at a significant amount in 2023, with expectations of continued growth through 2030. The CAGR for this region during the forecast period is anticipated to align with global trends, underscoring the importance of these dryers in enhancing agricultural productivity and reducing post-harvest losses. As the market evolves, advancements in technology and design are expected to further drive the adoption of Grain Heat Pump Dryers, making them an integral part of modern agricultural practices.

| Report Metric | Details |

| Report Name | Grain Heat Pump Dryer - Market |

| Forecasted market size in 2030 | US$ 334.8 million |

| CAGR | 5.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | PHNIX, Shuntec, Kinkai Tech, Ekotec, Drytech, AIM Energy, Baixin Machinery, IKE Group, TongYi Heat Pump, Di Ye Energy |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |