What is Global Plasma Water Table Fluid Market?

The Global Plasma Water Table Fluid Market is a specialized segment within the broader industrial fluids market. Plasma water table fluid is primarily used in plasma cutting tables to cool and stabilize the cutting process, reduce smoke and dust, and improve the overall quality of the cut. This fluid is essential in various industries, including automotive, aerospace, and metal fabrication, where precision cutting of metals is crucial. The market for plasma water table fluid is driven by the increasing demand for high-quality metal cutting and the growing adoption of advanced manufacturing technologies. Additionally, the need for efficient and environmentally friendly cutting processes has led to the development of innovative plasma water table fluids that offer superior performance and reduced environmental impact. The market is characterized by a diverse range of products, each designed to meet specific cutting requirements and operational conditions. As industries continue to evolve and adopt more sophisticated cutting technologies, the demand for plasma water table fluid is expected to grow, making it a vital component in modern manufacturing processes.

Bottled, Barreled in the Global Plasma Water Table Fluid Market:

In the Global Plasma Water Table Fluid Market, bottled and barreled products play a significant role in meeting the diverse needs of various industries. Bottled plasma water table fluid is typically packaged in smaller quantities, ranging from a few liters to several gallons, making it convenient for small to medium-sized enterprises or workshops that require precise amounts of fluid for their operations. These bottled products are easy to handle, store, and transport, ensuring that users can maintain a consistent supply without the need for large storage facilities. On the other hand, barreled plasma water table fluid is packaged in larger quantities, often in drums or barrels, which can hold up to hundreds of liters. This packaging format is ideal for large-scale industrial operations that consume significant amounts of fluid on a regular basis. Barreled products offer cost advantages due to bulk purchasing and reduced packaging waste, making them a preferred choice for high-volume users. Both bottled and barreled plasma water table fluids are formulated to provide optimal cooling, lubrication, and stabilization during the plasma cutting process. They help in minimizing thermal distortion, reducing slag formation, and extending the lifespan of cutting equipment. The choice between bottled and barreled products depends on the scale of operations, storage capabilities, and specific requirements of the end-users. In addition to the packaging formats, the quality and composition of the plasma water table fluid are crucial factors that influence its performance. Manufacturers offer a range of formulations, including water-based, oil-based, and synthetic fluids, each designed to meet different cutting conditions and material types. Water-based fluids are popular due to their environmental friendliness and ease of disposal, while oil-based and synthetic fluids offer enhanced lubrication and cooling properties for more demanding applications. The market also sees a trend towards the development of eco-friendly and biodegradable plasma water table fluids, driven by increasing environmental regulations and the need for sustainable manufacturing practices. These innovative products aim to reduce the environmental impact of industrial processes while maintaining high performance and efficiency. Overall, the Global Plasma Water Table Fluid Market is characterized by a wide variety of products and packaging options, catering to the diverse needs of industries involved in precision metal cutting. The choice between bottled and barreled products, along with the selection of appropriate formulations, plays a crucial role in ensuring optimal performance and efficiency in plasma cutting operations.

Direct Selling, Distributor in the Global Plasma Water Table Fluid Market:

The usage of Global Plasma Water Table Fluid Market products in direct selling and distribution channels is essential for reaching a wide range of customers and ensuring the availability of high-quality fluids for various industrial applications. Direct selling involves manufacturers or suppliers selling plasma water table fluids directly to end-users, such as metal fabrication shops, automotive manufacturers, and aerospace companies. This approach allows for a more personalized sales experience, where suppliers can provide tailored recommendations and technical support to meet the specific needs of their customers. Direct selling also enables manufacturers to build strong relationships with their clients, ensuring customer loyalty and repeat business. Additionally, direct selling can help in gathering valuable feedback from end-users, which can be used to improve product formulations and performance. On the other hand, distribution channels involve intermediaries, such as wholesalers, distributors, and retailers, who purchase plasma water table fluids from manufacturers and sell them to end-users. This approach allows for a broader market reach, as distributors often have established networks and logistics capabilities to ensure timely delivery of products to various locations. Distributors can also provide value-added services, such as inventory management, technical support, and training, which can enhance the overall customer experience. By leveraging distribution channels, manufacturers can focus on product development and innovation while relying on their partners to handle sales and distribution. Both direct selling and distribution channels play a crucial role in the Global Plasma Water Table Fluid Market, ensuring that high-quality fluids are available to meet the diverse needs of industries involved in precision metal cutting. The choice between direct selling and distribution depends on factors such as the scale of operations, target market, and customer preferences. In some cases, manufacturers may adopt a hybrid approach, combining direct selling with distribution channels to maximize market reach and customer satisfaction. This strategy allows for greater flexibility and adaptability in meeting the evolving demands of the market. Overall, the effective use of direct selling and distribution channels is essential for the growth and success of the Global Plasma Water Table Fluid Market, ensuring that industries have access to the best products and services to support their cutting operations.

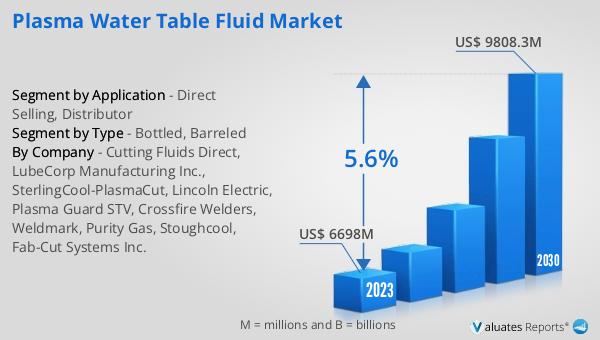

Global Plasma Water Table Fluid Market Outlook:

The global Plasma Water Table Fluid market was valued at US$ 6698 million in 2023 and is anticipated to reach US$ 9808.3 million by 2030, witnessing a CAGR of 5.6% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the plasma water table fluid market over the next several years. The increasing demand for high-quality metal cutting and the adoption of advanced manufacturing technologies are key drivers of this growth. As industries such as automotive, aerospace, and metal fabrication continue to evolve, the need for efficient and environmentally friendly cutting processes will drive the demand for innovative plasma water table fluids. The market is expected to see a steady increase in value, reflecting the growing importance of these fluids in modern manufacturing processes. The projected CAGR of 5.6% indicates a healthy growth rate, suggesting that the market will continue to expand and offer new opportunities for manufacturers and suppliers. This positive outlook underscores the importance of plasma water table fluids in achieving precision cutting and enhancing the overall efficiency of industrial operations.

| Report Metric | Details |

| Report Name | Plasma Water Table Fluid Market |

| Accounted market size in 2023 | US$ 6698 million |

| Forecasted market size in 2030 | US$ 9808.3 million |

| CAGR | 5.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Cutting Fluids Direct, LubeCorp Manufacturing Inc., SterlingCool-PlasmaCut, Lincoln Electric, Plasma Guard STV, Crossfire Welders, Weldmark, Purity Gas, Stoughcool, Fab-Cut Systems Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |