What is Glass-lined Thin Film Evaporator - Global Market?

Glass-lined thin film evaporators are specialized equipment used in various industries for the efficient evaporation of liquids. These devices are designed with a glass lining to prevent corrosion and contamination, making them ideal for handling sensitive or corrosive materials. The global market for glass-lined thin film evaporators is driven by their increasing demand in industries such as chemicals, pharmaceuticals, and food processing. These evaporators are known for their ability to handle high-viscosity liquids and heat-sensitive materials, providing a gentle yet effective evaporation process. The glass lining ensures that the product remains pure and uncontaminated, which is crucial in industries where product integrity is paramount. As industries continue to seek efficient and reliable evaporation solutions, the demand for glass-lined thin film evaporators is expected to grow, driven by technological advancements and the need for sustainable processing methods. The market is characterized by a diverse range of applications, with manufacturers focusing on innovation to meet the specific needs of different sectors. Overall, the glass-lined thin film evaporator market is poised for steady growth, supported by its versatility and the increasing emphasis on high-quality processing equipment.

L-Rotor, P-Rotor in the Glass-lined Thin Film Evaporator - Global Market:

In the realm of glass-lined thin film evaporators, L-Rotor and P-Rotor designs play a crucial role in enhancing the efficiency and effectiveness of the evaporation process. The L-Rotor design is characterized by its unique configuration, which allows for optimal distribution of the liquid film across the evaporator's surface. This design is particularly beneficial for handling high-viscosity liquids, as it ensures a consistent and uniform film formation, leading to efficient heat transfer and evaporation. The L-Rotor's ability to maintain a thin film even with viscous materials makes it a preferred choice in industries where product consistency and quality are critical. On the other hand, the P-Rotor design offers a different set of advantages. It is engineered to provide enhanced turbulence within the evaporator, which significantly improves the heat transfer rate. This design is particularly effective for low-viscosity liquids, where rapid evaporation is desired. The P-Rotor's ability to create a highly turbulent environment ensures that the liquid is evenly distributed and that the evaporation process is swift and efficient. Both L-Rotor and P-Rotor designs are integral to the functionality of glass-lined thin film evaporators, each catering to specific needs based on the nature of the liquid being processed. The choice between these designs depends on various factors, including the viscosity of the liquid, the desired evaporation rate, and the specific requirements of the application. Manufacturers of glass-lined thin film evaporators continue to innovate and refine these rotor designs to meet the evolving demands of the global market. As industries seek more efficient and reliable evaporation solutions, the importance of choosing the right rotor design becomes increasingly evident. The L-Rotor and P-Rotor designs exemplify the advancements in evaporator technology, offering tailored solutions that enhance the overall performance and efficiency of the evaporation process. In conclusion, the L-Rotor and P-Rotor designs are pivotal components of glass-lined thin film evaporators, each offering distinct advantages that cater to the diverse needs of various industries. Their continued development and refinement are essential to meeting the growing demand for high-quality evaporation solutions in the global market.

Chemical, Medical, Food, Others in the Glass-lined Thin Film Evaporator - Global Market:

Glass-lined thin film evaporators find extensive usage across various industries, including chemical, medical, food, and others, due to their unique capabilities and advantages. In the chemical industry, these evaporators are indispensable for processes that require the concentration of solutions, recovery of solvents, and purification of products. The glass lining ensures that corrosive chemicals do not damage the equipment, thereby extending its lifespan and maintaining the purity of the processed materials. This is particularly important in the production of high-purity chemicals and pharmaceuticals, where contamination can have significant consequences. In the medical field, glass-lined thin film evaporators are used for the preparation of active pharmaceutical ingredients (APIs) and other sensitive compounds. The gentle evaporation process preserves the integrity of heat-sensitive materials, ensuring that the final product retains its efficacy and quality. This is crucial in the pharmaceutical industry, where the slightest deviation in product quality can impact patient safety and treatment outcomes. In the food industry, these evaporators are employed for the concentration of food products, such as fruit juices, dairy products, and flavorings. The ability to handle high-viscosity liquids and maintain product quality makes them ideal for food processing applications. The glass lining prevents any interaction between the food product and the equipment, ensuring that the final product is free from contaminants and retains its natural flavor and nutritional value. Beyond these industries, glass-lined thin film evaporators are also used in sectors such as cosmetics, where they aid in the production of creams, lotions, and other personal care products. The versatility and reliability of these evaporators make them a valuable asset in any industry that requires efficient and high-quality evaporation processes. As industries continue to prioritize sustainability and efficiency, the demand for glass-lined thin film evaporators is expected to rise, driven by their ability to deliver consistent and reliable results across a wide range of applications.

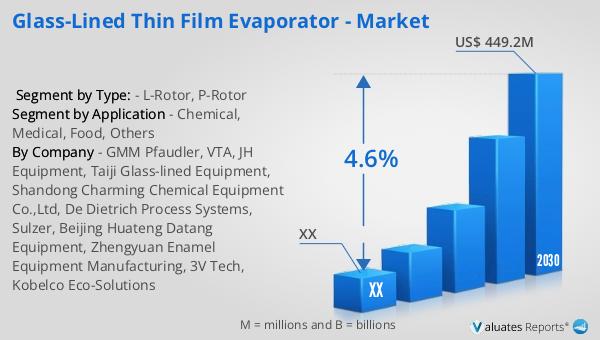

Glass-lined Thin Film Evaporator - Global Market Outlook:

The global market for glass-lined thin film evaporators was valued at approximately $325 million in 2023. It is projected to grow to a revised size of $449.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and reliable evaporation solutions across various industries. The North American market, in particular, is expected to contribute significantly to this growth, although specific figures for this region were not provided. The steady increase in market size underscores the importance of glass-lined thin film evaporators in modern industrial processes, where the need for high-quality and contamination-free evaporation is paramount. As industries continue to evolve and seek sustainable processing methods, the role of glass-lined thin film evaporators is likely to become even more critical. The market's expansion is driven by technological advancements, the growing emphasis on product quality, and the need for equipment that can handle a wide range of materials and applications. Overall, the outlook for the glass-lined thin film evaporator market is positive, with steady growth anticipated over the coming years.

| Report Metric | Details |

| Report Name | Glass-lined Thin Film Evaporator - Market |

| Forecasted market size in 2030 | US$ 449.2 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | GMM Pfaudler, VTA, JH Equipment, Taiji Glass-lined Equipment, Shandong Charming Chemical Equipment Co.,Ltd, De Dietrich Process Systems, Sulzer, Beijing Huateng Datang Equipment, Zhengyuan Enamel Equipment Manufacturing, 3V Tech, Kobelco Eco-Solutions |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |