What is Universal Joint Dynamic Balancing Machine - Global Market?

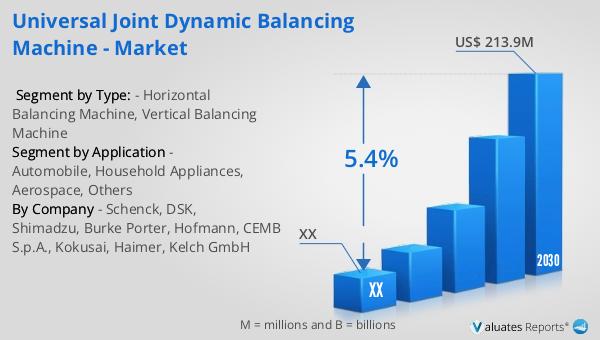

The Universal Joint Dynamic Balancing Machine is a specialized piece of equipment used to measure and correct the balance of rotating components. This machine is crucial in various industries where precision and balance are paramount, such as automotive, aerospace, and manufacturing. The global market for these machines was valued at approximately US$ 149 million in 2023. It is anticipated to grow to a size of US$ 213.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.4% from 2024 to 2030. This growth is driven by the increasing demand for high-performance machinery and the need for enhanced operational efficiency across industries. The machine works by detecting imbalances in rotating parts, which can cause vibrations, noise, and wear, leading to reduced performance and potential failure. By correcting these imbalances, the Universal Joint Dynamic Balancing Machine ensures smoother operation, longer lifespan, and improved safety of machinery. The North American market, in particular, is expected to see significant growth, although specific figures were not provided. This indicates a growing recognition of the importance of precision balancing in maintaining the integrity and efficiency of mechanical systems.

Horizontal Balancing Machine, Vertical Balancing Machine in the Universal Joint Dynamic Balancing Machine - Global Market:

Horizontal and vertical balancing machines are two primary types of equipment used in the Universal Joint Dynamic Balancing Machine market. Horizontal balancing machines are designed to balance components that are longer in length and have a horizontal axis of rotation. These machines are typically used for balancing rotors, crankshafts, and other elongated components. They work by supporting the component at both ends and rotating it to detect any imbalance. The machine then calculates the amount and location of the imbalance, allowing for precise correction. Horizontal balancing machines are favored in industries where components are predominantly cylindrical and require high precision, such as automotive and heavy machinery manufacturing. On the other hand, vertical balancing machines are used for components that are shorter and have a vertical axis of rotation. These machines are ideal for balancing components like flywheels, fans, and disc-shaped parts. The component is mounted vertically, and the machine spins it to identify any imbalance. Vertical balancing machines are often used in industries where components are compact and require quick balancing, such as in the production of household appliances and small motors. Both types of machines play a crucial role in ensuring the smooth operation and longevity of mechanical systems. They help reduce vibrations, noise, and wear, which can lead to improved performance and reduced maintenance costs. The choice between horizontal and vertical balancing machines depends on the specific requirements of the component being balanced, including its size, shape, and application. As the global market for Universal Joint Dynamic Balancing Machines continues to grow, advancements in technology are expected to enhance the precision and efficiency of both horizontal and vertical balancing machines. This will further drive their adoption across various industries, contributing to the overall growth of the market.

Automobile, Household Appliances, Aerospace, Others in the Universal Joint Dynamic Balancing Machine - Global Market:

The Universal Joint Dynamic Balancing Machine finds extensive usage across several key industries, including automobiles, household appliances, aerospace, and others. In the automobile industry, these machines are essential for balancing components such as crankshafts, camshafts, and wheels. Proper balancing of these components is crucial for ensuring smooth engine operation, reducing vibrations, and enhancing vehicle performance. By using dynamic balancing machines, manufacturers can improve the efficiency and reliability of vehicles, leading to better fuel economy and reduced emissions. In the household appliances sector, dynamic balancing machines are used to balance components like washing machine drums, fans, and motors. Balancing these components helps reduce noise and vibrations, leading to quieter and more efficient appliances. This is particularly important in modern households where noise reduction is a key consideration for consumers. In the aerospace industry, the precision offered by dynamic balancing machines is critical for ensuring the safety and performance of aircraft components. Balancing turbines, rotors, and other critical parts helps prevent mechanical failures and enhances the overall reliability of aircraft. The use of these machines in the aerospace sector is driven by stringent safety standards and the need for high-performance components. Beyond these industries, dynamic balancing machines are also used in sectors such as power generation, marine, and industrial machinery. In power generation, they help balance turbines and generators, ensuring efficient energy production and reducing maintenance costs. In the marine industry, balancing machines are used for propellers and shafts, contributing to smoother and more efficient vessel operation. Overall, the versatility and precision of Universal Joint Dynamic Balancing Machines make them indispensable across a wide range of applications, driving their demand in the global market.

Universal Joint Dynamic Balancing Machine - Global Market Outlook:

The global market outlook for Universal Joint Dynamic Balancing Machines indicates a promising future. In 2023, the market was valued at approximately US$ 149 million, and it is projected to expand to US$ 213.9 million by 2030. This growth represents a compound annual growth rate (CAGR) of 5.4% from 2024 to 2030. This upward trend is fueled by the increasing demand for precision and efficiency in various industries, including automotive, aerospace, and manufacturing. The North American market, in particular, is expected to experience significant growth during this period, although specific figures were not provided. This growth can be attributed to the region's strong industrial base and the increasing adoption of advanced manufacturing technologies. As industries continue to prioritize operational efficiency and product quality, the demand for dynamic balancing machines is expected to rise. These machines play a crucial role in ensuring the smooth operation and longevity of mechanical systems by detecting and correcting imbalances in rotating components. By doing so, they help reduce vibrations, noise, and wear, leading to improved performance and reduced maintenance costs. As the market continues to evolve, advancements in technology are expected to enhance the precision and efficiency of these machines, further driving their adoption across various industries.

| Report Metric | Details |

| Report Name | Universal Joint Dynamic Balancing Machine - Market |

| Forecasted market size in 2030 | US$ 213.9 million |

| CAGR | 5.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Schenck, DSK, Shimadzu, Burke Porter, Hofmann, CEMB S.p.A., Kokusai, Haimer, Kelch GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |