What is Global Glass Cutting Fluids Market?

The Global Glass Cutting Fluids Market refers to the industry that produces and supplies fluids specifically designed for the cutting and shaping of glass materials. These fluids play a crucial role in the glass manufacturing process by providing lubrication and cooling, which helps to reduce friction and heat generated during cutting. This, in turn, minimizes the risk of glass breakage and ensures a smoother, more precise cut. The market encompasses a wide range of products, including pure oils, soluble oils, synthetic liquids, and semi-synthetic liquids, each tailored to meet specific cutting requirements and performance standards. The demand for glass cutting fluids is driven by various industries such as automotive, construction, electronics, and optical, where precision and quality in glass cutting are paramount. As technology advances and the need for high-quality glass products increases, the Global Glass Cutting Fluids Market continues to evolve, offering innovative solutions to meet the growing demands of these industries.

Pure Oil, Soluble Oil, Synthetic Liquid, Semi-Synthetic Liquid in the Global Glass Cutting Fluids Market:

Pure oil, soluble oil, synthetic liquid, and semi-synthetic liquid are the primary types of fluids used in the Global Glass Cutting Fluids Market, each with distinct characteristics and applications. Pure oils are typically composed of mineral or petroleum-based oils and are known for their excellent lubrication properties. They provide a high level of protection against wear and tear, making them ideal for heavy-duty glass cutting operations. However, pure oils can be less effective in cooling, which can be a drawback in high-temperature cutting processes. Soluble oils, on the other hand, are a mixture of oil and water, forming an emulsion when mixed with water. This type of fluid offers a good balance between lubrication and cooling, making it suitable for a wide range of glass cutting applications. Soluble oils are particularly effective in reducing heat and preventing glass from cracking or breaking during the cutting process. Synthetic liquids are entirely man-made and do not contain any petroleum-based oils. They are designed to offer superior cooling and lubrication properties, making them highly effective in high-precision glass cutting operations. Synthetic liquids are also known for their stability and long shelf life, which can be advantageous in industrial settings. Semi-synthetic liquids combine the properties of both synthetic and soluble oils, offering a balanced performance in terms of lubrication, cooling, and stability. They are versatile and can be used in various glass cutting applications, providing a cost-effective solution without compromising on performance. Each type of fluid has its own set of advantages and limitations, and the choice of fluid often depends on the specific requirements of the cutting operation, such as the type of glass being cut, the cutting speed, and the desired finish.

Optical Glass, Plate Glass in the Global Glass Cutting Fluids Market:

The usage of Global Glass Cutting Fluids Market in areas such as optical glass and plate glass is essential for achieving high-quality cuts and ensuring the longevity of the cutting tools. In the optical glass industry, precision is of utmost importance as the glass is used in applications such as lenses, mirrors, and other optical components. The cutting fluids used in this industry must provide excellent lubrication and cooling to prevent any damage to the delicate glass surfaces. Pure oils and synthetic liquids are often preferred in optical glass cutting due to their superior lubrication properties, which help in achieving smooth and precise cuts. Additionally, these fluids help in reducing the heat generated during the cutting process, thereby minimizing the risk of thermal damage to the glass. In the plate glass industry, which involves the production of large, flat glass sheets used in windows, doors, and other architectural applications, the cutting fluids must be able to handle the high-speed cutting operations and provide effective cooling to prevent glass breakage. Soluble oils and semi-synthetic liquids are commonly used in plate glass cutting as they offer a good balance between lubrication and cooling. These fluids help in reducing friction and heat, ensuring a clean and precise cut while also extending the life of the cutting tools. The choice of cutting fluid in both optical and plate glass industries is crucial for maintaining the quality of the final product and optimizing the cutting process.

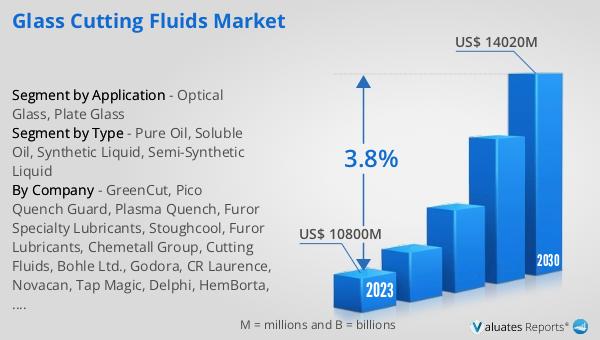

Global Glass Cutting Fluids Market Outlook:

The global Glass Cutting Fluids market, valued at US$ 10,800 million in 2023, is projected to grow to US$ 14,020 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for high-quality glass products across various industries, including automotive, construction, electronics, and optical. The market's expansion can be attributed to advancements in glass cutting technology and the continuous development of innovative cutting fluids that enhance the efficiency and precision of the cutting process. As industries strive for higher standards of quality and performance, the need for specialized cutting fluids that offer superior lubrication and cooling properties becomes more pronounced. The projected growth also underscores the importance of ongoing research and development in the field of glass cutting fluids, as manufacturers seek to meet the evolving needs of their customers and stay competitive in the global market.

| Report Metric | Details |

| Report Name | Glass Cutting Fluids Market |

| Accounted market size in 2023 | US$ 10800 million |

| Forecasted market size in 2030 | US$ 14020 million |

| CAGR | 3.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GreenCut, Pico Quench Guard, Plasma Quench, Furor Specialty Lubricants, Stoughcool, Furor Lubricants, Chemetall Group, Cutting Fluids, Bohle Ltd., Godora, CR Laurence, Novacan, Tap Magic, Delphi, HemBorta, Creative Glass Guild, Impresa, EnviroGold, Inland Craft, CONDAT, Aquasol, KOG, Talamoni |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |