What is Ultrasonic Wire Welding Machine - Global Market?

The Ultrasonic Wire Welding Machine is a specialized piece of equipment used in various industries to join wires using ultrasonic vibrations. This technology is highly efficient and precise, making it an ideal choice for applications where traditional welding methods might fall short. The global market for these machines is expanding as industries seek more reliable and cost-effective solutions for wire joining. Ultrasonic wire welding machines operate by using high-frequency ultrasonic acoustic vibrations to create a solid-state weld. This process does not require additional materials like solder or adhesives, making it environmentally friendly and reducing production costs. The demand for these machines is driven by their ability to produce strong, reliable welds quickly and with minimal energy consumption. As industries such as automotive, electronics, and aerospace continue to grow, the need for efficient and reliable wire welding solutions is expected to increase, further driving the market for ultrasonic wire welding machines. The global market for these machines was valued at approximately $254 million in 2023 and is projected to grow significantly in the coming years.

Low-pressure Welding, High-pressure Welding in the Ultrasonic Wire Welding Machine - Global Market:

Low-pressure and high-pressure welding are two distinct methods used in ultrasonic wire welding machines, each with its own set of advantages and applications. Low-pressure welding is typically used for delicate or thin materials where excessive pressure could cause damage. This method relies on the precise application of ultrasonic vibrations to create a weld without the need for high pressure. It is particularly useful in industries such as electronics and medical devices, where components are often small and fragile. The low-pressure approach ensures that the integrity of the materials is maintained while still achieving a strong bond. On the other hand, high-pressure welding is used for applications that require a more robust weld. This method involves applying greater pressure in conjunction with ultrasonic vibrations to create a strong, durable bond. High-pressure welding is often used in industries such as automotive and aerospace, where the components being joined are larger and require a more substantial weld. The choice between low-pressure and high-pressure welding depends on the specific requirements of the application, including the materials being used and the desired strength of the weld. Both methods offer unique benefits and are integral to the versatility of ultrasonic wire welding machines in the global market. As the demand for more efficient and reliable welding solutions continues to grow, the use of both low-pressure and high-pressure welding techniques is expected to expand across various industries. The ability to choose between these two methods allows manufacturers to tailor their welding processes to meet the specific needs of their products, ensuring optimal performance and quality. This flexibility is one of the key factors driving the adoption of ultrasonic wire welding machines in the global market. As industries continue to evolve and new applications for ultrasonic welding are discovered, the demand for both low-pressure and high-pressure welding solutions is expected to increase, further fueling the growth of the ultrasonic wire welding machine market.

Automobile, Instrumentation, Hardware, Household Appliances, Others in the Ultrasonic Wire Welding Machine - Global Market:

The usage of ultrasonic wire welding machines spans across various industries, each benefiting from the unique advantages offered by this technology. In the automotive industry, these machines are used to join electrical wires and components, ensuring reliable connections that are crucial for the performance and safety of vehicles. The precision and efficiency of ultrasonic welding make it an ideal choice for the complex wiring systems found in modern automobiles. In the field of instrumentation, ultrasonic wire welding machines are used to assemble sensitive electronic components. The low-pressure welding technique is particularly beneficial here, as it allows for the joining of delicate parts without causing damage. This ensures the integrity and functionality of the instruments, which is essential for accurate measurements and data collection. In the hardware industry, ultrasonic wire welding machines are used to create strong, durable connections between metal components. The high-pressure welding technique is often employed in this sector to ensure the strength and longevity of the welds. This is particularly important in applications where the hardware is subjected to high levels of stress or wear. Household appliances also benefit from the use of ultrasonic wire welding machines. These machines are used to join electrical components within appliances, ensuring reliable performance and safety. The ability to create strong, consistent welds quickly and efficiently makes ultrasonic welding an attractive option for manufacturers looking to improve the quality and reliability of their products. Beyond these specific industries, ultrasonic wire welding machines are also used in a variety of other applications. From aerospace to telecommunications, the versatility and efficiency of ultrasonic welding make it a valuable tool for manufacturers across the globe. As the demand for more reliable and cost-effective welding solutions continues to grow, the use of ultrasonic wire welding machines is expected to expand into new areas, further driving the growth of the global market.

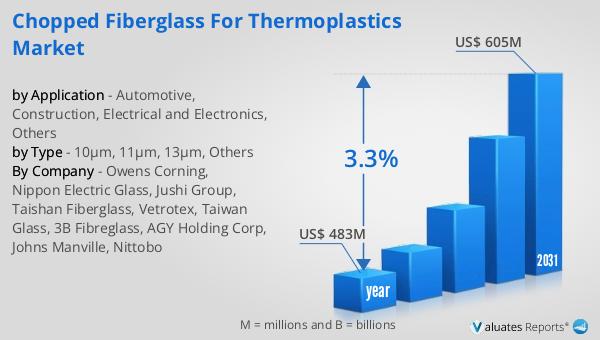

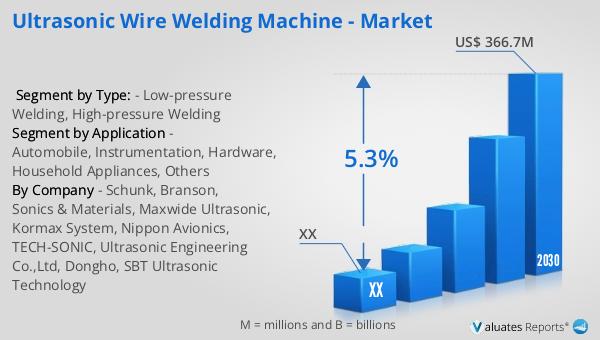

Ultrasonic Wire Welding Machine - Global Market Outlook:

The global market for Ultrasonic Wire Welding Machines was valued at approximately $254 million in 2023, with projections indicating a significant increase to around $366.7 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. The North American market, in particular, is poised for substantial growth, although specific figures for this region were not provided. The increasing demand for efficient and reliable wire welding solutions across various industries is a key factor driving this market expansion. As industries such as automotive, electronics, and aerospace continue to evolve, the need for advanced welding technologies like ultrasonic wire welding machines is becoming more pronounced. These machines offer numerous advantages, including precision, efficiency, and environmental benefits, making them an attractive option for manufacturers worldwide. The projected growth of the global market reflects the increasing adoption of ultrasonic wire welding machines as industries seek to improve the quality and reliability of their products while reducing production costs. As the market continues to expand, manufacturers are likely to invest in research and development to further enhance the capabilities of these machines, ensuring they remain at the forefront of welding technology.

| Report Metric | Details |

| Report Name | Ultrasonic Wire Welding Machine - Market |

| Forecasted market size in 2030 | US$ 366.7 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Schunk, Branson, Sonics & Materials, Maxwide Ultrasonic, Kormax System, Nippon Avionics, TECH-SONIC, Ultrasonic Engineering Co.,Ltd, Dongho, SBT Ultrasonic Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |