What is High Frequency Heat Sealing Machine - Global Market?

High Frequency Heat Sealing Machines are specialized devices used in various industries to seal materials using high-frequency electromagnetic waves. These machines are particularly effective for sealing thermoplastic materials, which are plastics that become pliable or moldable at a certain elevated temperature and solidify upon cooling. The global market for these machines is expanding due to their efficiency and versatility in creating airtight and watertight seals, which are essential in many applications. High Frequency Heat Sealing Machines are commonly used in industries such as packaging, medical, automotive, and textiles, where they help in sealing products like blister packs, medical bags, and automotive components. The machines operate by generating high-frequency electromagnetic waves that cause the molecules in the plastic to vibrate, generating heat and causing the material to melt and fuse together. This process ensures a strong and durable seal, which is crucial for maintaining the integrity and safety of the packaged products. As industries continue to demand more efficient and reliable sealing solutions, the market for High Frequency Heat Sealing Machines is expected to grow, driven by technological advancements and the increasing need for high-quality packaging solutions.

Continuous Type, Intermittent Type in the High Frequency Heat Sealing Machine - Global Market:

High Frequency Heat Sealing Machines can be categorized into two main types: Continuous Type and Intermittent Type. Continuous Type machines are designed for high-speed operations and are ideal for applications where a constant flow of materials needs to be sealed. These machines are often used in large-scale production environments where efficiency and speed are critical. They operate by continuously feeding materials through the sealing area, allowing for a seamless and uninterrupted sealing process. This type of machine is particularly beneficial in industries such as food packaging, where large volumes of products need to be sealed quickly and efficiently. On the other hand, Intermittent Type machines are designed for applications where precision and control are more important than speed. These machines operate by sealing materials in a stop-and-go manner, allowing for greater control over the sealing process. This makes them ideal for applications where the quality of the seal is paramount, such as in the medical industry, where the integrity of the seal can directly impact the safety and efficacy of medical products. Intermittent Type machines are also commonly used in the automotive industry, where they are used to seal components that require a high degree of precision and reliability. Both types of machines have their own unique advantages and are used in different applications depending on the specific needs of the industry. The choice between Continuous and Intermittent Type machines often depends on factors such as the volume of production, the type of materials being sealed, and the specific requirements of the application. As the global market for High Frequency Heat Sealing Machines continues to grow, manufacturers are constantly innovating and developing new technologies to improve the efficiency and effectiveness of these machines. This includes advancements in automation, which allow for greater precision and control over the sealing process, as well as improvements in energy efficiency, which help to reduce the environmental impact of these machines. Additionally, manufacturers are also focusing on developing machines that are more user-friendly and easier to operate, which can help to reduce the learning curve for operators and improve overall productivity. As a result, both Continuous and Intermittent Type High Frequency Heat Sealing Machines are expected to see increased demand in the coming years, driven by the growing need for efficient and reliable sealing solutions across a wide range of industries.

Medical Industry, Packaging Industry in the High Frequency Heat Sealing Machine - Global Market:

High Frequency Heat Sealing Machines play a crucial role in the medical and packaging industries, where they are used to create strong and reliable seals that are essential for maintaining the integrity and safety of products. In the medical industry, these machines are used to seal a wide range of products, including medical bags, IV bags, and sterile packaging for medical devices. The ability to create airtight and watertight seals is critical in this industry, as it helps to prevent contamination and ensure the safety and efficacy of medical products. High Frequency Heat Sealing Machines are also used to seal blister packs for pharmaceuticals, which help to protect the medication from moisture and other environmental factors that could compromise its effectiveness. In the packaging industry, these machines are used to seal a variety of products, including food packaging, blister packs, and flexible packaging. The ability to create strong and durable seals is essential in this industry, as it helps to protect the contents of the package from damage and contamination during transportation and storage. High Frequency Heat Sealing Machines are particularly beneficial in the packaging industry because they can create seals quickly and efficiently, which helps to improve productivity and reduce costs. Additionally, these machines are also used to seal packaging for consumer goods, such as electronics and household products, where the quality of the seal is important for maintaining the integrity and safety of the product. As the demand for high-quality packaging solutions continues to grow, the use of High Frequency Heat Sealing Machines in the packaging industry is expected to increase, driven by the need for efficient and reliable sealing solutions. Overall, High Frequency Heat Sealing Machines are an essential tool in both the medical and packaging industries, where they help to ensure the safety and quality of products by creating strong and reliable seals.

High Frequency Heat Sealing Machine - Global Market Outlook:

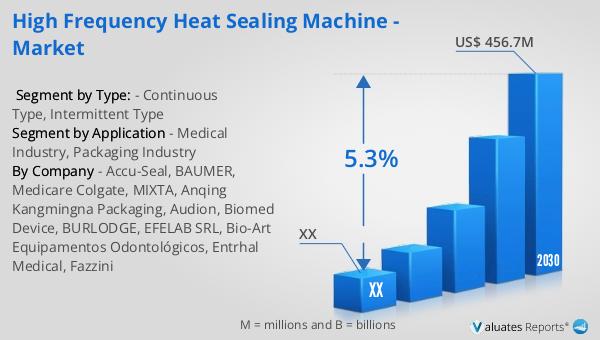

The global market for High Frequency Heat Sealing Machines was valued at approximately $317 million in 2023. It is projected to grow to a revised size of $456.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and reliable sealing solutions across various industries. In North America, the market for High Frequency Heat Sealing Machines was valued at a certain amount in 2023, and it is expected to reach a specific value by 2030, with a CAGR of a certain percentage during the forecast period from 2024 through 2030. This growth in the North American market can be attributed to the rising demand for high-quality packaging solutions and the increasing adoption of advanced sealing technologies in the region. As industries continue to prioritize efficiency and reliability in their sealing processes, the market for High Frequency Heat Sealing Machines is expected to see significant growth in the coming years, driven by technological advancements and the increasing need for high-quality packaging solutions.

| Report Metric | Details |

| Report Name | High Frequency Heat Sealing Machine - Market |

| Forecasted market size in 2030 | US$ 456.7 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Accu-Seal, BAUMER, Medicare Colgate, MIXTA, Anqing Kangmingna Packaging, Audion, Biomed Device, BURLODGE, EFELAB SRL, Bio-Art Equipamentos Odontológicos, Entrhal Medical, Fazzini |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |