What is Multilayer Metal Sintering Screen - Global Market?

Multilayer metal sintering screens are a crucial component in various industrial applications, offering enhanced filtration and separation capabilities. These screens are composed of multiple layers of metal mesh that are sintered together, creating a robust and durable structure. The sintering process involves heating the metal layers to a temperature below their melting point, causing them to bond at a molecular level. This results in a screen that is not only strong but also resistant to high temperatures and corrosive environments. The global market for multilayer metal sintering screens is driven by their widespread use in industries such as oil and gas, chemical processing, and food and beverage production. These screens are valued for their ability to provide precise filtration, ensuring the removal of contaminants and impurities from liquids and gases. As industries continue to demand higher efficiency and reliability in their processes, the demand for multilayer metal sintering screens is expected to grow. Their versatility and durability make them an essential component in modern industrial operations, contributing to improved product quality and operational efficiency.

Three Floors, Five Floors, Seven Floors, Others in the Multilayer Metal Sintering Screen - Global Market:

In the global market for multilayer metal sintering screens, the number of layers in the screen plays a significant role in determining its application and effectiveness. Screens with three, five, and seven layers, as well as other configurations, are available to meet the specific needs of different industries. Three-layer screens are typically used in applications where moderate filtration is required. They offer a balance between strength and permeability, making them suitable for processes that involve the separation of larger particles. These screens are often used in industries such as food and beverage, where they help ensure product purity without compromising flow rates. Five-layer screens provide enhanced filtration capabilities, making them ideal for more demanding applications. The additional layers increase the screen's strength and allow for finer filtration, which is essential in industries like chemical processing and pharmaceuticals. These screens can effectively remove smaller particles, ensuring the purity and quality of the final product. Seven-layer screens offer the highest level of filtration and durability. They are used in industries where the separation of very fine particles is critical, such as in the oil and gas sector. These screens can withstand high pressures and temperatures, making them suitable for challenging environments. Other configurations, such as screens with more than seven layers, are also available for specialized applications. These screens are custom-designed to meet the unique requirements of specific industries, providing tailored solutions for complex filtration challenges. The choice of screen configuration depends on factors such as the size and nature of the particles to be filtered, the operating conditions, and the desired level of filtration. As industries continue to evolve and demand more efficient and reliable filtration solutions, the market for multilayer metal sintering screens is expected to expand. The versatility and adaptability of these screens make them a valuable asset in a wide range of industrial applications, contributing to improved process efficiency and product quality.

Cement, Electricity Generation, Mining, Others in the Multilayer Metal Sintering Screen - Global Market:

Multilayer metal sintering screens are widely used in various industries, including cement, electricity generation, and mining, due to their superior filtration and separation capabilities. In the cement industry, these screens play a crucial role in ensuring the quality and consistency of the final product. They are used in the filtration of raw materials and the separation of fine particles from the cement mixture. This helps in maintaining the desired particle size distribution, which is essential for the strength and durability of the cement. The screens also contribute to the efficient operation of cement production processes by preventing the clogging of equipment and reducing downtime. In electricity generation, multilayer metal sintering screens are used in the filtration of cooling water and the separation of impurities from fuel sources. This is critical for maintaining the efficiency and reliability of power plants. The screens help in preventing the buildup of contaminants in the system, which can lead to equipment failure and reduced power output. By ensuring the purity of the cooling water and fuel, these screens contribute to the smooth operation of electricity generation processes. In the mining industry, multilayer metal sintering screens are used in the separation of valuable minerals from ore. They are employed in various stages of the mining process, including the filtration of slurry and the separation of fine particles from the extracted material. The screens help in improving the efficiency of mineral extraction processes by ensuring the removal of impurities and maximizing the recovery of valuable resources. This contributes to the profitability and sustainability of mining operations. In addition to these industries, multilayer metal sintering screens are also used in other applications, such as wastewater treatment and air filtration. Their versatility and durability make them suitable for a wide range of industrial processes, where they help in improving product quality and operational efficiency. As industries continue to seek more efficient and reliable filtration solutions, the demand for multilayer metal sintering screens is expected to grow, driving the expansion of the global market.

Multilayer Metal Sintering Screen - Global Market Outlook:

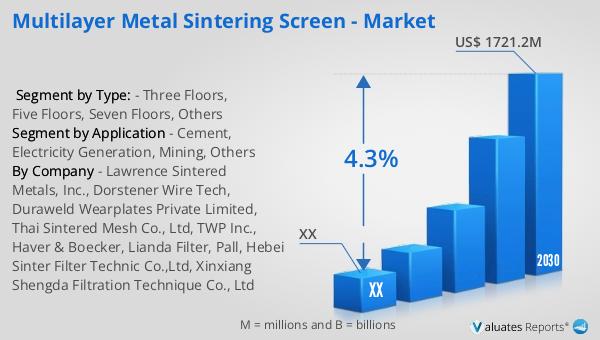

The global market for multilayer metal sintering screens was valued at approximately $1,233 million in 2023. It is projected to grow to a size of around $1,721.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for efficient and reliable filtration solutions across various industries. In North America, the market for multilayer metal sintering screens was valued at a certain amount in 2023 and is expected to reach a higher value by 2030, with a CAGR of a specific percentage during the forecast period. The growth in this region is attributed to the presence of well-established industries and the increasing adoption of advanced filtration technologies. The market outlook for multilayer metal sintering screens indicates a positive trend, with significant growth opportunities in both developed and emerging markets. As industries continue to prioritize efficiency and sustainability, the demand for these screens is expected to rise, driving the expansion of the global market. The versatility and durability of multilayer metal sintering screens make them a valuable asset in a wide range of industrial applications, contributing to improved process efficiency and product quality.

| Report Metric | Details |

| Report Name | Multilayer Metal Sintering Screen - Market |

| Forecasted market size in 2030 | US$ 1721.2 million |

| CAGR | 4.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Lawrence Sintered Metals, Inc., Dorstener Wire Tech, Duraweld Wearplates Private Limited, Thai Sintered Mesh Co., Ltd, TWP Inc., Haver & Boecker, Lianda Filter, Pall, Hebei Sinter Filter Technic Co.,Ltd, Xinxiang Shengda Filtration Technique Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |