What is Electronic Component Screen Printing Machine - Global Market?

Electronic Component Screen Printing Machines are specialized devices used in the production of electronic components, where precision and accuracy are paramount. These machines are designed to apply conductive inks and pastes onto substrates, which are essential in creating circuits and other electronic components. The global market for these machines is driven by the increasing demand for miniaturized and efficient electronic devices. As technology advances, the need for more compact and high-performance electronic components grows, pushing manufacturers to adopt advanced screen printing techniques. These machines offer high precision, repeatability, and efficiency, making them indispensable in the electronics manufacturing industry. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the capabilities of these machines to cater to the evolving needs of the electronics sector. The growth of the global market is also supported by the rising adoption of automation in manufacturing processes, which further boosts the demand for these sophisticated machines. As industries strive for higher productivity and quality, the role of electronic component screen printing machines becomes increasingly significant.

Color Printing, Monochrome Printing in the Electronic Component Screen Printing Machine - Global Market:

Color printing and monochrome printing are two fundamental processes in the realm of electronic component screen printing machines, each serving distinct purposes and applications. Color printing involves the use of multiple inks to create a wide range of colors, which is crucial in applications where visual differentiation is necessary. This process is often employed in the production of components that require color coding or labeling for easy identification and assembly. The ability to print in color enhances the functionality and usability of electronic components, making them more user-friendly and efficient. On the other hand, monochrome printing uses a single color, typically black or a conductive ink, to create the necessary patterns and circuits on electronic components. This method is widely used in the production of printed circuit boards (PCBs) and other components where color differentiation is not required. Monochrome printing is favored for its simplicity, cost-effectiveness, and efficiency, making it a popular choice for high-volume production runs. The global market for electronic component screen printing machines is witnessing a growing demand for both color and monochrome printing capabilities, driven by the diverse needs of the electronics industry. Manufacturers are continuously innovating to enhance the precision, speed, and versatility of these machines, enabling them to cater to a wide range of applications. The integration of advanced technologies, such as digital printing and automation, is further transforming the landscape of electronic component screen printing, offering new possibilities and opportunities for growth. As the electronics industry continues to evolve, the demand for sophisticated printing solutions that can deliver high-quality results with minimal waste and downtime is expected to rise. This trend is likely to drive further advancements in both color and monochrome printing technologies, ensuring that electronic component screen printing machines remain at the forefront of innovation in the manufacturing sector.

Passive Electric Components, Active Electric Components in the Electronic Component Screen Printing Machine - Global Market:

Electronic component screen printing machines play a crucial role in the production of both passive and active electric components, each of which has distinct characteristics and applications. Passive electric components, such as resistors, capacitors, and inductors, do not require an external power source to operate and are essential in controlling the flow of electricity within a circuit. These components are often produced using screen printing techniques, which allow for precise deposition of conductive and dielectric materials onto substrates. The ability to accurately print these materials is critical in ensuring the performance and reliability of passive components, which are used in a wide range of electronic devices. The global market for electronic component screen printing machines is driven by the increasing demand for high-quality passive components, which are essential in the development of advanced electronic systems. Active electric components, such as transistors, diodes, and integrated circuits, require an external power source to function and are responsible for amplifying, switching, or processing electrical signals. The production of these components often involves more complex screen printing processes, as they require the precise application of multiple layers of conductive and insulating materials. The global market for electronic component screen printing machines is witnessing a growing demand for advanced printing solutions that can meet the stringent requirements of active component production. Manufacturers are focusing on developing machines that offer high precision, repeatability, and efficiency, enabling them to produce active components with the necessary performance characteristics. The integration of advanced technologies, such as digital printing and automation, is further enhancing the capabilities of these machines, allowing them to cater to the evolving needs of the electronics industry. As the demand for more sophisticated electronic devices continues to grow, the role of electronic component screen printing machines in the production of both passive and active components is becoming increasingly important. This trend is expected to drive further advancements in screen printing technologies, ensuring that these machines remain at the forefront of innovation in the electronics manufacturing sector.

Electronic Component Screen Printing Machine - Global Market Outlook:

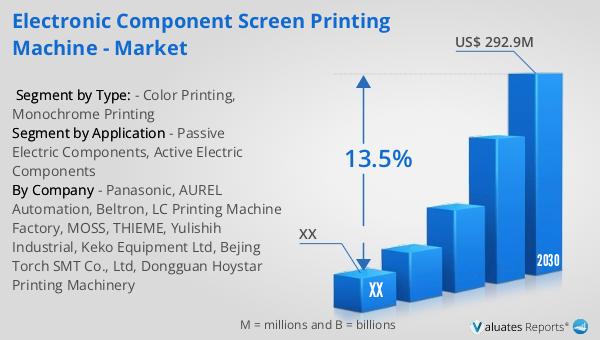

The market outlook for electronic component screen printing machines highlights their importance in the precise production of electronic components. These machines are specifically designed to handle a variety of screen printing applications, ensuring accuracy and efficiency in the manufacturing process. In 2023, the global market for these machines was valued at approximately US$ 119 million. Looking ahead, it is projected to expand significantly, reaching an estimated size of US$ 292.9 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 13.5% from 2024 to 2030. The North American market, in particular, is poised for substantial growth during this period, although specific figures for its valuation and growth rate were not provided. The increasing demand for miniaturized and high-performance electronic devices is a key driver of this market expansion. As industries continue to adopt automation and advanced manufacturing techniques, the need for sophisticated screen printing machines is expected to rise. This trend underscores the critical role these machines play in the electronics manufacturing sector, as they enable the production of high-quality components with precision and efficiency.

| Report Metric | Details |

| Report Name | Electronic Component Screen Printing Machine - Market |

| Forecasted market size in 2030 | US$ 292.9 million |

| CAGR | 13.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Panasonic, AUREL Automation, Beltron, LC Printing Machine Factory, MOSS, THIEME, Yulishih Industrial, Keko Equipment Ltd, Bejing Torch SMT Co., Ltd, Dongguan Hoystar Printing Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |