What is 3D Printed Spinal Implant - Global Market?

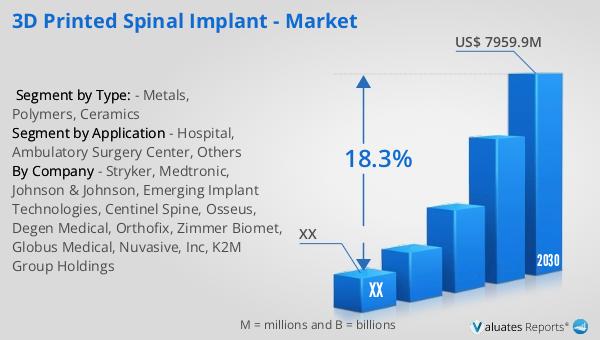

3D printed spinal implants represent a groundbreaking advancement in the field of medical technology, offering a tailored approach to spinal surgery. These implants are created using 3D printing technology, which allows for the production of highly customized implants that fit the unique anatomical needs of each patient. This customization is crucial in spinal surgeries, where precision is paramount to ensure successful outcomes and reduce the risk of complications. The global market for 3D printed spinal implants is expanding rapidly, driven by the increasing prevalence of spinal disorders and the growing demand for minimally invasive surgical procedures. As of 2023, the market was valued at approximately US$ 2,413 million, with projections indicating a significant growth trajectory, reaching an estimated US$ 7,959.9 million by 2030. This growth is fueled by technological advancements in 3D printing, increased healthcare spending, and a rising awareness of the benefits of personalized medicine. The ability to produce implants that are not only anatomically precise but also potentially more cost-effective and quicker to manufacture than traditional methods is a key factor driving this market forward. As healthcare systems worldwide continue to embrace innovative solutions, the role of 3D printed spinal implants is set to become increasingly prominent.

Metals, Polymers, Ceramics in the 3D Printed Spinal Implant - Global Market:

In the realm of 3D printed spinal implants, materials such as metals, polymers, and ceramics play a pivotal role in determining the functionality and success of the implants. Metals, particularly titanium and its alloys, are widely used due to their excellent strength-to-weight ratio, biocompatibility, and corrosion resistance. Titanium's ability to integrate with bone, known as osseointegration, makes it an ideal choice for spinal implants, ensuring stability and longevity. The use of metal in 3D printing allows for the creation of complex structures that mimic the natural architecture of bone, providing both support and flexibility. On the other hand, polymers offer a different set of advantages. Materials like PEEK (polyether ether ketone) are favored for their radiolucency, which means they do not interfere with imaging techniques such as X-rays, allowing for better post-operative monitoring. Polymers are also lightweight and can be engineered to have varying degrees of flexibility, making them suitable for applications where movement is necessary. Additionally, polymers can be combined with bioactive materials to promote bone growth and healing. Ceramics, though less commonly used than metals and polymers, offer unique benefits such as high compressive strength and excellent wear resistance. They are particularly useful in load-bearing applications and can be engineered to have bioactive properties that encourage bone growth. The choice of material in 3D printed spinal implants is crucial, as it impacts not only the mechanical properties of the implant but also its interaction with the body. Each material offers distinct advantages and challenges, and the selection often depends on the specific requirements of the patient and the intended application of the implant. As research and development in this field continue to advance, the potential for new materials and combinations thereof promises to further enhance the capabilities and applications of 3D printed spinal implants. The integration of these materials into the 3D printing process allows for the creation of implants that are not only tailored to the patient's anatomy but also optimized for performance and longevity. This customization is a significant advantage over traditional manufacturing methods, which often involve a one-size-fits-all approach. By leveraging the unique properties of metals, polymers, and ceramics, 3D printed spinal implants can offer improved outcomes for patients, reducing recovery times and enhancing the overall success of spinal surgeries. As the global market for these implants continues to grow, the exploration of new materials and technologies will likely lead to even more innovative solutions in the future.

Hospital, Ambulatory Surgery Center, Others in the 3D Printed Spinal Implant - Global Market:

The application of 3D printed spinal implants in various healthcare settings such as hospitals, ambulatory surgery centers, and other medical facilities is transforming the landscape of spinal surgery. In hospitals, these implants are increasingly being used in complex spinal surgeries where precision and customization are critical. The ability to produce patient-specific implants allows surgeons to plan and execute surgeries with greater accuracy, reducing the risk of complications and improving patient outcomes. Hospitals, with their advanced infrastructure and access to cutting-edge technology, are well-equipped to integrate 3D printing into their surgical procedures, offering patients the benefits of personalized medicine. Ambulatory surgery centers, which focus on providing same-day surgical care, are also adopting 3D printed spinal implants to enhance their service offerings. These centers benefit from the reduced surgical times and quicker recovery associated with the use of customized implants. The minimally invasive nature of surgeries involving 3D printed implants aligns well with the goals of ambulatory centers to provide efficient and effective care. Additionally, the cost-effectiveness of 3D printing technology makes it an attractive option for these centers, which often operate with tighter budgets than larger hospitals. Beyond hospitals and ambulatory centers, other medical facilities such as specialized spine clinics and research institutions are exploring the potential of 3D printed spinal implants. These facilities are often at the forefront of innovation, conducting research and clinical trials to further understand the capabilities and limitations of 3D printing in spinal surgery. The use of 3D printed implants in these settings not only enhances the quality of care provided to patients but also contributes to the broader body of knowledge in the field of spinal surgery. As the technology continues to evolve, the integration of 3D printed spinal implants across various healthcare settings is expected to increase, driven by the demand for personalized and efficient surgical solutions. The versatility and adaptability of 3D printing technology make it a valuable tool in the ongoing effort to improve patient care and outcomes in spinal surgery.

3D Printed Spinal Implant - Global Market Outlook:

The outlook for the global market of 3D printed spinal implants is promising, with significant growth anticipated over the coming years. In 2023, the market was valued at approximately US$ 2,413 million, and it is projected to expand to an estimated US$ 7,959.9 million by 2030, reflecting a robust compound annual growth rate (CAGR) of 18.3% during the forecast period from 2024 to 2030. This impressive growth is indicative of the increasing adoption of 3D printing technology in the medical field, particularly in the area of spinal surgery. The ability to produce highly customized implants that cater to the specific anatomical needs of patients is a key driver of this market expansion. Furthermore, the broader medical devices market, valued at US$ 603 billion in 2023, is also experiencing growth, albeit at a more moderate CAGR of 5% over the next six years. This growth is supported by advancements in medical technology, increased healthcare spending, and a growing awareness of the benefits of personalized medicine. As healthcare systems worldwide continue to embrace innovative solutions, the role of 3D printed spinal implants is set to become increasingly prominent, offering improved outcomes for patients and new opportunities for healthcare providers. The integration of 3D printing technology into the medical devices market is not only transforming the way surgeries are performed but also paving the way for future innovations in patient care.

| Report Metric | Details |

| Report Name | 3D Printed Spinal Implant - Market |

| Forecasted market size in 2030 | US$ 7959.9 million |

| CAGR | 18.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Stryker, Medtronic, Johnson & Johnson, Emerging Implant Technologies, Centinel Spine, Osseus, Degen Medical, Orthofix, Zimmer Biomet, Globus Medical, Nuvasive, Inc, K2M Group Holdings |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |