What is Global m-Aminophenol Market?

The global m-Aminophenol market is a specialized segment within the broader chemical industry. m-Aminophenol, also known as 3-Aminophenol, is an organic compound with the formula C6H7NO. It is a white to light brown crystalline solid that is soluble in water and alcohol. This compound is primarily used as an intermediate in the synthesis of various dyes, pharmaceuticals, and agrochemicals. The market for m-Aminophenol is driven by its extensive applications in these industries, as well as its role in the production of rubber chemicals and antioxidants. The demand for m-Aminophenol is influenced by factors such as industrial growth, technological advancements, and regulatory policies. The global market is characterized by the presence of several key players who are engaged in the production and distribution of m-Aminophenol, catering to the needs of various end-use industries. The market dynamics are shaped by supply chain factors, raw material availability, and competitive pricing strategies. Overall, the global m-Aminophenol market is poised for steady growth, driven by its diverse applications and the increasing demand from emerging economies.

Purity 99.5%, Purity 99% in the Global m-Aminophenol Market:

In the global m-Aminophenol market, the purity of the product is a critical factor that determines its suitability for various applications. Two common grades of m-Aminophenol are Purity 99.5% and Purity 99%. The Purity 99.5% grade is considered to be of higher quality and is often used in applications that require stringent specifications, such as in the pharmaceutical and dye industries. This high-purity grade ensures minimal impurities, which is crucial for achieving consistent and reliable results in sensitive applications. On the other hand, the Purity 99% grade is slightly lower in quality but is still suitable for a wide range of industrial applications. This grade is often used in the production of agrochemicals, rubber chemicals, and other industrial products where the presence of minor impurities does not significantly impact the performance of the end product. The choice between these two grades depends on the specific requirements of the application and the cost considerations. Manufacturers and suppliers in the global m-Aminophenol market offer both grades to cater to the diverse needs of their customers. The availability of different purity grades allows end-users to select the most appropriate product for their specific applications, ensuring optimal performance and cost-effectiveness. The production process for achieving these purity levels involves advanced purification techniques and stringent quality control measures to ensure that the final product meets the required specifications. The global m-Aminophenol market is thus characterized by a range of product offerings that cater to the varying needs of different industries, with purity being a key differentiating factor.

Dyes, Pesticide, Other in the Global m-Aminophenol Market:

The global m-Aminophenol market finds extensive usage in various applications, including dyes, pesticides, and other industrial products. In the dye industry, m-Aminophenol is used as an intermediate in the synthesis of azo dyes, which are widely used for coloring textiles, leather, and paper. The compound's ability to produce vibrant and stable colors makes it a preferred choice for dye manufacturers. Additionally, m-Aminophenol is used in the production of hair dyes, where its high purity and consistent quality are essential for achieving the desired color and performance. In the pesticide industry, m-Aminophenol is used as a building block for the synthesis of various agrochemicals. Its role as an intermediate in the production of herbicides, insecticides, and fungicides is crucial for ensuring the effectiveness and safety of these products. The compound's chemical properties make it suitable for creating active ingredients that target specific pests and diseases, thereby contributing to improved crop yields and agricultural productivity. Beyond dyes and pesticides, m-Aminophenol is also used in the production of rubber chemicals, antioxidants, and pharmaceuticals. In the rubber industry, it is used as an antioxidant to prevent the degradation of rubber products, thereby extending their lifespan and performance. In the pharmaceutical industry, m-Aminophenol serves as an intermediate in the synthesis of various drugs, including analgesics and antipyretics. Its high purity and consistent quality are essential for ensuring the safety and efficacy of pharmaceutical products. Overall, the diverse applications of m-Aminophenol in different industries highlight its versatility and importance as a chemical intermediate. The global market for m-Aminophenol is driven by the demand from these end-use industries, with each application requiring specific grades and purity levels to meet their unique requirements.

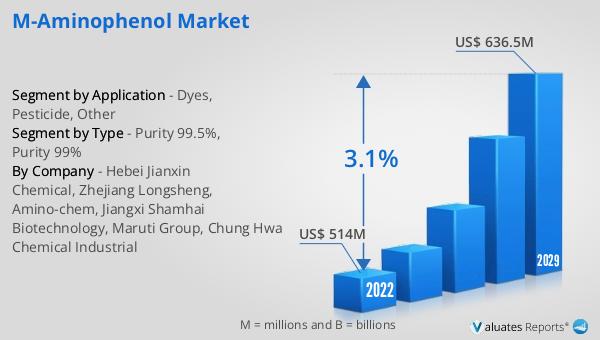

Global m-Aminophenol Market Outlook:

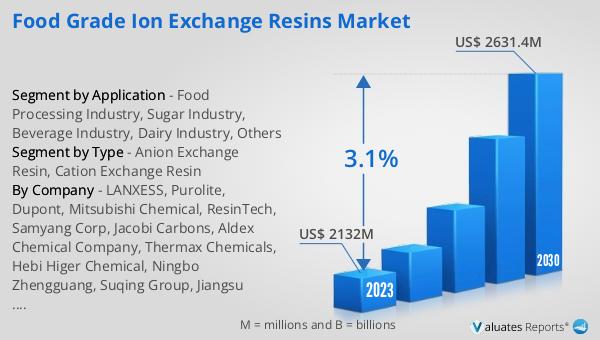

The global m-Aminophenol market was valued at US$ 514 million in 2023 and is anticipated to reach US$ 636.5 million by 2030, witnessing a CAGR of 3.1% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for m-Aminophenol across various industries. The compound's extensive applications in the production of dyes, pesticides, rubber chemicals, and pharmaceuticals contribute to its growing market value. The projected growth reflects the compound's importance as a chemical intermediate and its role in enhancing the performance and quality of end products. The market dynamics are influenced by factors such as industrial growth, technological advancements, and regulatory policies that impact the production and usage of m-Aminophenol. The presence of key players in the market, who are engaged in the production and distribution of high-quality m-Aminophenol, further supports the market's growth prospects. As industries continue to seek reliable and high-purity chemical intermediates, the demand for m-Aminophenol is expected to remain robust, driving the market towards its anticipated value by 2030.

| Report Metric | Details |

| Report Name | m-Aminophenol Market |

| Accounted market size in 2023 | US$ 514 million |

| Forecasted market size in 2030 | US$ 636.5 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hebei Jianxin Chemical, Zhejiang Longsheng, Amino-chem, Jiangxi Shamhai Biotechnology, Maruti Group, Chung Hwa Chemical Industrial |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |