What is Global High Speed Precision Electric Spindle Market?

The Global High Speed Precision Electric Spindle Market is a specialized segment within the broader machinery and equipment industry. This market focuses on the production and distribution of high-speed precision electric spindles, which are critical components in various high-precision machining applications. These spindles are designed to operate at very high speeds while maintaining exceptional accuracy and stability, making them indispensable in industries that require meticulous machining processes. The market encompasses a wide range of spindle types, including those with different bearing systems and cooling mechanisms, tailored to meet the specific needs of diverse applications. The demand for these spindles is driven by the increasing need for high-precision manufacturing in sectors such as electronics, automotive, aerospace, and machinery manufacturing. As industries continue to push the boundaries of precision and efficiency, the Global High Speed Precision Electric Spindle Market is expected to grow, driven by technological advancements and the rising adoption of automation in manufacturing processes.

Roller Bearing Electro-spindle, Air Bearing Electro-spindle, Liquid Sliding Bearing Electro-spindle, Other in the Global High Speed Precision Electric Spindle Market:

The Global High Speed Precision Electric Spindle Market includes various types of spindles, each designed to meet specific requirements and applications. Roller Bearing Electro-spindles are among the most common types, known for their robustness and ability to handle high loads. These spindles use roller bearings to support the rotating shaft, providing excellent rigidity and precision. They are widely used in applications where high load capacity and durability are essential. Air Bearing Electro-spindles, on the other hand, use a thin film of air to support the spindle shaft, eliminating mechanical contact and thus reducing friction and wear. This results in extremely high precision and speed capabilities, making them ideal for ultra-precision machining tasks. Liquid Sliding Bearing Electro-spindles utilize a liquid film to support the spindle shaft, offering a balance between the high precision of air bearings and the load capacity of roller bearings. These spindles are suitable for applications requiring both high precision and moderate load handling. Other types of spindles in this market include magnetic bearing spindles and hybrid bearing spindles, which combine different bearing technologies to achieve specific performance characteristics. Each type of spindle has its unique advantages and is selected based on the specific needs of the application, such as speed, precision, load capacity, and environmental conditions. The diversity of spindle types in the Global High Speed Precision Electric Spindle Market ensures that there is a suitable solution for virtually any high-precision machining requirement.

Printed Circuit Board, Consumer Electronics, Machinery Manufacturing, Automotive and Aerospace, Other in the Global High Speed Precision Electric Spindle Market:

The usage of high-speed precision electric spindles spans across various industries, each benefiting from the unique capabilities of these advanced components. In the Printed Circuit Board (PCB) industry, these spindles are crucial for drilling and routing tasks that require extreme precision and high speeds. The ability to maintain tight tolerances and produce clean, accurate holes is essential for the functionality of PCBs, making high-speed precision spindles indispensable in this sector. In the Consumer Electronics industry, these spindles are used in the manufacturing of components such as smartphone parts, where precision and speed are critical to meet the high production volumes and stringent quality standards. Machinery Manufacturing also relies heavily on high-speed precision spindles for tasks such as milling, grinding, and drilling. The ability to achieve high precision and efficiency in these processes directly impacts the quality and performance of the machinery produced. In the Automotive and Aerospace industries, high-speed precision spindles are used for machining engine components, turbine blades, and other critical parts that require exceptional accuracy and surface finish. The high speeds and precision offered by these spindles enable manufacturers to meet the demanding specifications and safety standards of these industries. Other applications of high-speed precision electric spindles include medical device manufacturing, where precision and cleanliness are paramount, and the production of optical components, where surface finish and accuracy are critical. The versatility and performance of high-speed precision electric spindles make them essential tools in a wide range of high-precision manufacturing applications.

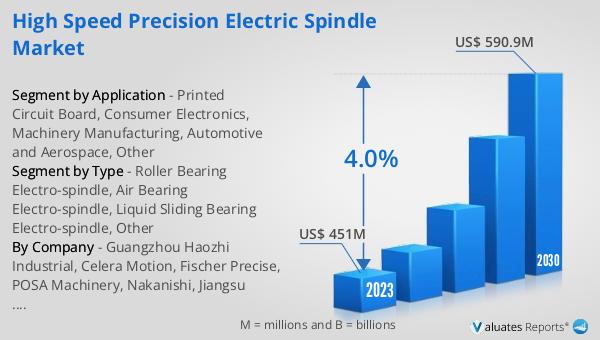

Global High Speed Precision Electric Spindle Market Outlook:

The global High Speed Precision Electric Spindle market was valued at US$ 451 million in 2023 and is anticipated to reach US$ 590.9 million by 2030, witnessing a CAGR of 4.0% during the forecast period from 2024 to 2030. This market growth reflects the increasing demand for high-precision machining solutions across various industries. The rising adoption of automation and advanced manufacturing technologies is driving the need for high-speed precision spindles that can deliver exceptional accuracy and efficiency. As industries such as electronics, automotive, aerospace, and machinery manufacturing continue to evolve, the demand for these advanced spindles is expected to grow. The market's expansion is also supported by ongoing technological advancements in spindle design and materials, which enhance performance and reliability. The projected growth of the Global High Speed Precision Electric Spindle Market underscores the critical role these components play in modern manufacturing processes, enabling industries to achieve higher levels of precision, productivity, and quality.

| Report Metric | Details |

| Report Name | High Speed Precision Electric Spindle Market |

| Accounted market size in 2023 | US$ 451 million |

| Forecasted market size in 2030 | US$ 590.9 million |

| CAGR | 4.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Guangzhou Haozhi Industrial, Celera Motion, Fischer Precise, POSA Machinery, Nakanishi, Jiangsu Xingchen High-Speed Electric Motor, PARFAITE Enterprise, IBAG Group, Siemens, GMN, Kessler |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |