What is Global Tert-Dodecyl Mercaptan Market?

The Global Tert-Dodecyl Mercaptan Market is a specialized sector within the chemical industry that focuses on the production and distribution of Tert-Dodecyl Mercaptan (TDM). TDM is a type of organic compound that is primarily used as a chain transfer agent in the production of polymers. It is a colorless liquid with a strong odor, and it is known for its ability to react with other substances to create new compounds. The market for TDM is global in nature, with demand stemming from various industries around the world. However, it is important to note that the market is not evenly distributed across all regions. Certain areas have a higher demand for TDM due to the presence of industries that heavily rely on this compound.

TDM Products Based on Dodecene, TDM Products Based on Propylene in the Global Tert-Dodecyl Mercaptan Market:

The Global Tert-Dodecyl Mercaptan Market is divided into two main product categories: TDM Products Based on Dodecene and TDM Products Based on Propylene. TDM Products Based on Dodecene are created through a chemical reaction between dodecene and sulfur. This type of TDM is known for its high purity and is often used in applications that require a high level of precision. On the other hand, TDM Products Based on Propylene are made by reacting propylene with sulfur. This type of TDM is less pure than its dodecene-based counterpart, but it is also less expensive to produce. Both types of TDM have their own unique set of advantages and disadvantages, and the choice between the two often depends on the specific needs of the end user.

Styrene–Butadiene Rubber (SBR), Nitrile Rubber (NBR), Acrylonitrile Butadiene Styrene (ABS), Surfactant, Others in the Global Tert-Dodecyl Mercaptan Market:

The Global Tert-Dodecyl Mercaptan Market serves a wide range of industries, including the production of Styrene–Butadiene Rubber (SBR), Nitrile Rubber (NBR), Acrylonitrile Butadiene Styrene (ABS), Surfactants, and others. SBR is a type of synthetic rubber that is used in a variety of applications, from car tires to conveyor belts. TDM is used in the production of SBR to control the molecular weight of the polymer, which in turn affects its physical properties. NBR, another type of synthetic rubber, also relies on TDM for the same reason. ABS is a type of plastic that is known for its toughness and impact resistance. TDM is used in the production of ABS to improve its processability. Surfactants, substances that reduce the surface tension of liquids, are another major application of TDM. TDM is used in the production of surfactants to control their molecular weight and improve their performance. Other industries that use TDM include the production of adhesives, sealants, and coatings.

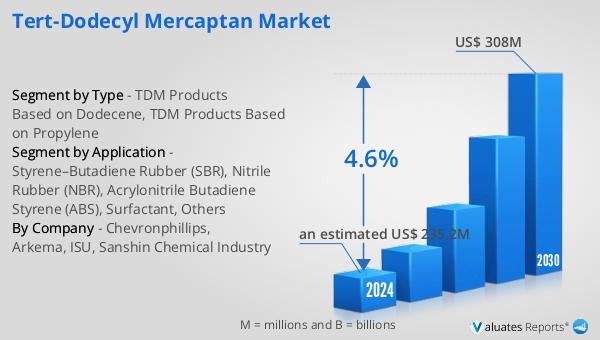

Global Tert-Dodecyl Mercaptan Market Outlook:

The Global Tert-Dodecyl Mercaptan Market is currently experiencing steady growth. In 2022, the market was valued at US$ 224 million. It is projected to reach a value of US$ 308 million by 2029, growing at a compound annual growth rate (CAGR) of 4.6% from 2023 to 2029. The market is dominated by a small number of companies, with the top two firms holding a combined market share of approximately 82%. In terms of regional distribution, Europe is the largest market for TDM, accounting for about 50% of the total market share. It is followed by North America and Asia Pacific, which hold market shares of approximately 32% and 17% respectively.

| Report Metric | Details |

| Report Name | Tert-Dodecyl Mercaptan Market |

| Accounted market size in 2022 | US$ 224 million |

| Forecasted market size in 2029 | US$ 308 million |

| CAGR | 4.6% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Chevronphillips, Arkema, ISU, Sanshin Chemical Industry |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |