What is Global Tandem Press Line Market?

The Global Tandem Press Line Market is a specialized segment within the manufacturing industry that focuses on the production and utilization of tandem press lines. These are sophisticated systems used in various industrial applications to shape and form metal sheets into desired configurations. Tandem press lines consist of multiple presses arranged in a sequence, allowing for the continuous processing of materials. This setup enhances efficiency and productivity by enabling the simultaneous execution of multiple operations, such as cutting, bending, and forming. The market for tandem press lines is driven by the demand for high-volume production capabilities, precision, and automation in manufacturing processes. Industries such as automotive, aerospace, and consumer goods rely on these systems to produce components with consistent quality and minimal waste. As technology advances, tandem press lines are becoming more versatile, incorporating features like servo drives and automation to meet the evolving needs of manufacturers. The global market for these systems is expanding as industries seek to optimize their production processes and reduce operational costs. The tandem press line market is characterized by innovation and competition, with manufacturers continually developing new technologies to enhance performance and efficiency.

Mechanical, Servo, Hybrid in the Global Tandem Press Line Market:

In the Global Tandem Press Line Market, three primary types of systems are prevalent: Mechanical, Servo, and Hybrid. Each of these systems offers unique advantages and is suited to different manufacturing needs. Mechanical tandem press lines are the traditional choice, known for their robustness and reliability. They operate using a mechanical flywheel that stores energy and releases it to drive the press. This type of system is favored for its simplicity and cost-effectiveness, making it ideal for high-volume production environments where precision is not the primary concern. However, mechanical systems can be limited in terms of flexibility and energy efficiency, which has led to the development of more advanced alternatives. Servo tandem press lines represent a significant advancement in press technology. These systems utilize servo motors to control the movement of the press, offering unparalleled precision and flexibility. The use of servo technology allows for precise control over the press speed, stroke, and position, enabling manufacturers to produce complex parts with high accuracy. Additionally, servo systems are more energy-efficient than their mechanical counterparts, as they only consume power when needed. This efficiency, combined with the ability to quickly change setups and adapt to different production requirements, makes servo tandem press lines a popular choice in industries where precision and adaptability are crucial. Hybrid tandem press lines combine the best features of both mechanical and servo systems. These systems use a combination of mechanical components and servo motors to deliver a balance of power, precision, and efficiency. Hybrid systems are designed to offer the robustness and cost-effectiveness of mechanical presses while incorporating the precision and flexibility of servo technology. This makes them suitable for a wide range of applications, from high-volume production to specialized manufacturing processes. The versatility of hybrid systems allows manufacturers to optimize their production lines for different types of products, reducing downtime and increasing overall productivity. The choice between mechanical, servo, and hybrid tandem press lines depends on several factors, including the specific requirements of the manufacturing process, budget constraints, and desired production outcomes. Mechanical systems are often chosen for their simplicity and lower initial cost, making them suitable for straightforward, high-volume production tasks. Servo systems, on the other hand, are preferred in scenarios where precision and adaptability are paramount, despite their higher initial investment. Hybrid systems offer a middle ground, providing a balance of cost, performance, and flexibility that can be tailored to a variety of manufacturing needs. As the Global Tandem Press Line Market continues to evolve, manufacturers are increasingly looking for systems that offer not only high performance but also sustainability and energy efficiency. This has led to a growing interest in servo and hybrid systems, which are seen as more environmentally friendly options due to their reduced energy consumption and ability to minimize waste. Additionally, advancements in automation and digital technology are further enhancing the capabilities of tandem press lines, allowing for greater integration with other manufacturing systems and improved overall efficiency. In conclusion, the Global Tandem Press Line Market is characterized by a diverse range of systems, each offering distinct advantages and suited to different manufacturing environments. Whether opting for the traditional reliability of mechanical systems, the precision of servo technology, or the versatility of hybrid solutions, manufacturers have a wealth of options to choose from. As industries continue to demand more efficient and adaptable production processes, the market for tandem press lines is poised for continued growth and innovation.

Automotive, Home Applicants, Others in the Global Tandem Press Line Market:

The Global Tandem Press Line Market finds extensive usage across various industries, with significant applications in the automotive, home appliances, and other sectors. In the automotive industry, tandem press lines are crucial for the mass production of vehicle components. These systems are used to manufacture parts such as body panels, chassis components, and structural elements, which require high precision and consistency. The ability of tandem press lines to perform multiple operations in a single pass makes them ideal for the automotive sector, where efficiency and speed are paramount. As the automotive industry continues to evolve, with a focus on lightweight materials and electric vehicles, tandem press lines are being adapted to handle new materials and complex designs, further driving their adoption. In the home appliances sector, tandem press lines play a vital role in the production of various components used in products like refrigerators, washing machines, and ovens. These systems enable manufacturers to produce large quantities of parts with consistent quality, ensuring that appliances meet the required standards and specifications. The flexibility of tandem press lines allows for the production of a wide range of components, from simple panels to intricate parts, catering to the diverse needs of the home appliances industry. As consumer demand for innovative and energy-efficient appliances grows, manufacturers are increasingly relying on tandem press lines to enhance their production capabilities and meet market expectations. Beyond automotive and home appliances, the Global Tandem Press Line Market serves a variety of other industries, including aerospace, electronics, and construction. In the aerospace sector, tandem press lines are used to produce lightweight and durable components essential for aircraft manufacturing. The precision and reliability of these systems are critical in ensuring the safety and performance of aerospace components. Similarly, in the electronics industry, tandem press lines are employed to manufacture parts for devices such as smartphones, computers, and other electronic gadgets. The ability to produce small, intricate components with high accuracy makes tandem press lines indispensable in this sector. In the construction industry, tandem press lines are used to produce metal components for building structures, such as beams, columns, and panels. The robustness and efficiency of these systems enable the production of large quantities of construction materials, supporting the industry's demand for rapid and cost-effective building solutions. Additionally, tandem press lines are increasingly being used in the production of renewable energy components, such as wind turbine parts and solar panel frames, as the world shifts towards more sustainable energy sources. Overall, the Global Tandem Press Line Market is integral to a wide range of industries, providing the tools necessary for efficient and high-quality production. As technology advances and industries continue to evolve, the demand for tandem press lines is expected to grow, driven by the need for precision, efficiency, and adaptability in manufacturing processes. The versatility and capabilities of tandem press lines make them a valuable asset in meeting the diverse needs of modern industries, ensuring their continued relevance and importance in the global market.

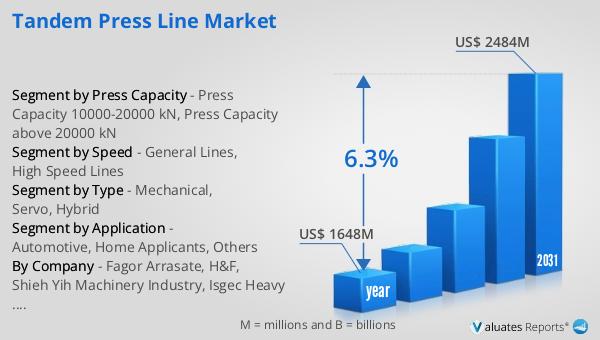

Global Tandem Press Line Market Outlook:

The global market for Tandem Press Line was valued at $1,648 million in 2024 and is anticipated to expand to a revised size of $2,484 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.3% over the forecast period. This growth trajectory underscores the increasing demand for tandem press lines across various industries, driven by the need for efficient, high-volume production capabilities. As manufacturers seek to optimize their operations and reduce costs, the adoption of advanced tandem press line systems is becoming more prevalent. The market's expansion is also fueled by technological advancements that enhance the performance and versatility of these systems, making them suitable for a broader range of applications. With industries such as automotive, aerospace, and consumer goods continually evolving, the demand for precision and automation in manufacturing processes is on the rise. This has led to a growing interest in tandem press lines, which offer the ability to produce complex parts with high accuracy and minimal waste. As the market continues to grow, manufacturers are investing in research and development to create innovative solutions that meet the changing needs of their customers. The future of the Global Tandem Press Line Market looks promising, with opportunities for growth and innovation on the horizon.

| Report Metric | Details |

| Report Name | Tandem Press Line Market |

| Accounted market size in year | US$ 1648 million |

| Forecasted market size in 2031 | US$ 2484 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Press Capacity |

|

| Segment by Speed |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fagor Arrasate, H&F, Shieh Yih Machinery Industry, Isgec Heavy Engineering, Amada, YangLi Group, Aida, JIER, Lien Chieh Hydraulic Industrial, AP&T, SIEMPELKAMP Transport Systems, Komatsu, Güdel |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |