What is Global Resonant Acoustic Mixers (RAM) Market?

The Global Resonant Acoustic Mixers (RAM) Market is an intriguing segment within the broader field of mixing technologies, characterized by its unique approach to blending materials. Unlike traditional mixers that rely on impellers or blades, RAM technology uses acoustic energy to create a resonant effect that efficiently mixes substances. This method is particularly advantageous for materials that are sensitive to shear or require a uniform mix without the introduction of air. The market for RAM is driven by its application across various industries, including pharmaceuticals, chemicals, and battery materials, where precision and consistency are paramount. The technology's ability to handle a wide range of viscosities and densities makes it versatile and appealing to manufacturers looking to optimize their production processes. As industries continue to seek innovative solutions to improve efficiency and product quality, the demand for RAM technology is expected to grow, offering a promising outlook for stakeholders in this market. The global market for RAM is not only about the technology itself but also about the potential it holds for transforming traditional mixing processes into more efficient and effective operations.

Laboratory RAM, Pilot RAM, Industrial RAM in the Global Resonant Acoustic Mixers (RAM) Market:

In the Global Resonant Acoustic Mixers (RAM) Market, there are three primary types of RAM systems: Laboratory RAM, Pilot RAM, and Industrial RAM. Each of these systems serves a distinct purpose and caters to different stages of product development and production. Laboratory RAM systems are designed for small-scale applications, typically used in research and development settings. These systems allow scientists and engineers to experiment with formulations and processes on a manageable scale, providing valuable insights into how materials will behave when mixed using acoustic energy. The precision and control offered by Laboratory RAM systems make them ideal for testing new compounds or refining existing ones, ensuring that the desired properties are achieved before scaling up production. Pilot RAM systems, on the other hand, bridge the gap between laboratory research and full-scale production. They are used to validate processes and formulations developed in the lab, allowing manufacturers to test their viability in a more realistic production environment. Pilot RAM systems are crucial for identifying potential challenges and optimizing processes before committing to large-scale manufacturing. This stage is essential for minimizing risks and ensuring that the transition from development to production is as smooth as possible. Industrial RAM systems represent the final stage in the RAM hierarchy, designed for large-scale production environments. These systems are built to handle significant volumes of material, making them suitable for industries that require high throughput and consistent quality. Industrial RAM systems are engineered to withstand the demands of continuous operation, providing reliable performance and efficiency. The scalability of RAM technology, from laboratory to industrial applications, highlights its versatility and adaptability to various production needs. Each type of RAM system plays a critical role in the overall market, catering to the diverse requirements of different industries and ensuring that the benefits of acoustic mixing can be realized at every stage of the production process.

Pharmaceuticals, Battery Materials, Specialty Chemicals, Others in the Global Resonant Acoustic Mixers (RAM) Market:

The Global Resonant Acoustic Mixers (RAM) Market finds its applications across several key industries, each benefiting from the unique advantages offered by acoustic mixing technology. In the pharmaceutical industry, RAM technology is particularly valuable due to its ability to produce uniform mixtures without introducing shear forces that could degrade sensitive compounds. This is crucial for the development of pharmaceuticals where consistency and purity are paramount. RAM systems enable the precise blending of active pharmaceutical ingredients (APIs) with excipients, ensuring that each dose contains the correct amount of medication. This level of precision is essential for maintaining the efficacy and safety of pharmaceutical products. In the realm of battery materials, RAM technology plays a significant role in the production of advanced batteries. The ability to mix materials uniformly is critical for the performance and longevity of batteries, as inconsistencies can lead to reduced efficiency and lifespan. RAM systems facilitate the even distribution of conductive materials and active components, enhancing the overall quality of the battery. This is particularly important in the development of next-generation batteries, where performance and reliability are key differentiators. Specialty chemicals also benefit from the application of RAM technology. The production of specialty chemicals often involves complex formulations that require precise mixing to achieve the desired properties. RAM systems provide the control and consistency needed to produce high-quality specialty chemicals, enabling manufacturers to meet the stringent requirements of their customers. The versatility of RAM technology allows it to be used with a wide range of chemical compositions, making it an invaluable tool for the specialty chemicals industry. Beyond these specific industries, RAM technology is also used in various other applications where uniform mixing is essential. This includes the production of food and beverages, cosmetics, and even certain types of construction materials. The ability to mix materials without introducing air or shear makes RAM systems ideal for applications where product integrity and quality are critical. As industries continue to evolve and demand more efficient and effective production methods, the use of RAM technology is likely to expand, offering new opportunities for innovation and growth.

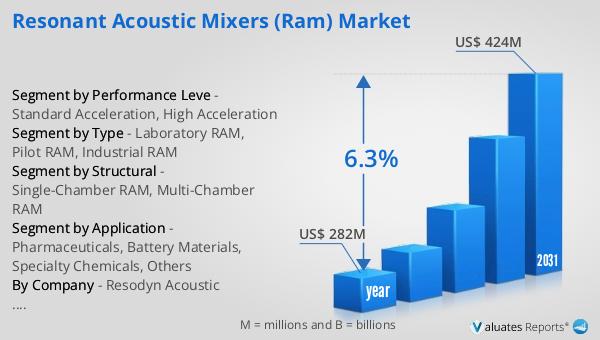

Global Resonant Acoustic Mixers (RAM) Market Outlook:

The global market for Resonant Acoustic Mixers (RAM) was valued at $282 million in 2024, with projections indicating a growth to $424 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.3% over the forecast period. The increasing demand for efficient and precise mixing solutions across various industries is a key driver of this market expansion. As manufacturers seek to improve product quality and production efficiency, the adoption of RAM technology is expected to rise. The versatility of RAM systems, which can handle a wide range of materials and applications, makes them an attractive option for companies looking to optimize their processes. Additionally, the growing focus on sustainability and reducing waste in manufacturing processes is likely to further boost the demand for RAM technology. By providing a more efficient and effective mixing solution, RAM systems can help companies reduce their environmental impact and improve their overall sustainability. As the market continues to grow, stakeholders in the RAM industry can expect to see new opportunities for innovation and expansion, driven by the increasing demand for advanced mixing solutions.

| Report Metric | Details |

| Report Name | Resonant Acoustic Mixers (RAM) Market |

| Accounted market size in year | US$ 282 million |

| Forecasted market size in 2031 | US$ 424 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Structural |

|

| Segment by Performance Leve |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Resodyn Acoustic Mixer, Zhengzhou Abrasives & Grinding Research Institut, PCCCA, Hummer Acoustic Mixers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |