What is Global Precision Seamless Pipe Market?

The Global Precision Seamless Pipe Market is a specialized segment within the broader pipe industry, focusing on the production and distribution of seamless pipes that are manufactured with high precision. These pipes are characterized by their ability to withstand high pressure and temperature, making them ideal for critical applications across various industries. Unlike welded pipes, seamless pipes are made without any joints or seams, which enhances their strength and durability. The market for these pipes is driven by the increasing demand from industries such as automotive, chemical, power, and aerospace, where precision and reliability are paramount. The seamless nature of these pipes ensures a uniform structure, which is crucial for applications that require high performance and safety standards. As industries continue to evolve and demand more efficient and reliable materials, the Global Precision Seamless Pipe Market is expected to grow, offering innovative solutions to meet the stringent requirements of modern engineering and manufacturing processes. The market's growth is also supported by advancements in manufacturing technologies, which enable the production of seamless pipes with enhanced properties and at competitive costs.

Cold Drawn, Cold Rolled in the Global Precision Seamless Pipe Market:

Cold drawn and cold rolled processes are two critical methods used in the manufacturing of precision seamless pipes, each offering distinct advantages and characteristics that cater to specific industrial needs. The cold drawn process involves pulling a pipe through a die to reduce its diameter and improve its mechanical properties. This method enhances the pipe's dimensional accuracy and surface finish, making it suitable for applications that require high precision and smooth surfaces. Cold drawn pipes are often used in industries where tight tolerances and superior surface quality are essential, such as in the production of hydraulic cylinders and automotive components. The process also increases the pipe's tensile strength and hardness, making it more resistant to wear and tear. On the other hand, the cold rolled process involves passing the pipe through a series of rollers to achieve the desired thickness and finish. This method is known for producing pipes with excellent surface quality and uniform thickness, which are crucial for applications that demand consistent performance and reliability. Cold rolled pipes are commonly used in the construction and manufacturing sectors, where they are valued for their strength and durability. Both cold drawn and cold rolled processes contribute significantly to the Global Precision Seamless Pipe Market by providing high-quality products that meet the diverse needs of various industries. The choice between these two methods depends on the specific requirements of the application, such as the desired mechanical properties, surface finish, and dimensional accuracy. As the demand for precision seamless pipes continues to grow, manufacturers are investing in advanced technologies and equipment to enhance the efficiency and quality of these processes. This investment is crucial for maintaining a competitive edge in the market and meeting the evolving needs of customers. Furthermore, the development of new materials and alloys is expanding the capabilities of cold drawn and cold rolled pipes, enabling them to perform in more demanding environments and applications. The synergy between these manufacturing processes and material innovations is driving the growth of the Global Precision Seamless Pipe Market, offering solutions that are both cost-effective and high-performing. As industries continue to push the boundaries of engineering and design, the role of precision seamless pipes, produced through cold drawn and cold rolled methods, will remain integral to achieving the desired outcomes in terms of quality, performance, and reliability.

Automotive Components, Chemical Industry, Power Industry, Aviation and Aerospace, Others in the Global Precision Seamless Pipe Market:

The Global Precision Seamless Pipe Market finds extensive usage across various industries, each benefiting from the unique properties and advantages offered by these high-quality pipes. In the automotive sector, precision seamless pipes are used in the manufacturing of critical components such as fuel injection systems, hydraulic cylinders, and exhaust systems. The high strength and durability of these pipes ensure the reliability and efficiency of automotive components, which are essential for vehicle performance and safety. In the chemical industry, seamless pipes are used to transport corrosive and high-temperature fluids, where their resistance to corrosion and ability to withstand extreme conditions are crucial. The precision and uniformity of these pipes ensure the safe and efficient operation of chemical processes, minimizing the risk of leaks and failures. The power industry also relies heavily on precision seamless pipes for applications such as boiler tubes, heat exchangers, and steam pipelines. The ability of these pipes to withstand high pressure and temperature makes them ideal for power generation applications, where reliability and efficiency are paramount. In the aviation and aerospace sectors, precision seamless pipes are used in the manufacturing of aircraft components, where their lightweight and high-strength properties contribute to the overall performance and safety of the aircraft. The use of seamless pipes in these industries underscores their importance in ensuring the reliability and efficiency of critical systems and processes. Additionally, other industries such as construction, oil and gas, and manufacturing also benefit from the use of precision seamless pipes, where their strength, durability, and precision are valued for various applications. As industries continue to evolve and demand more efficient and reliable materials, the Global Precision Seamless Pipe Market is poised to grow, offering innovative solutions to meet the stringent requirements of modern engineering and manufacturing processes.

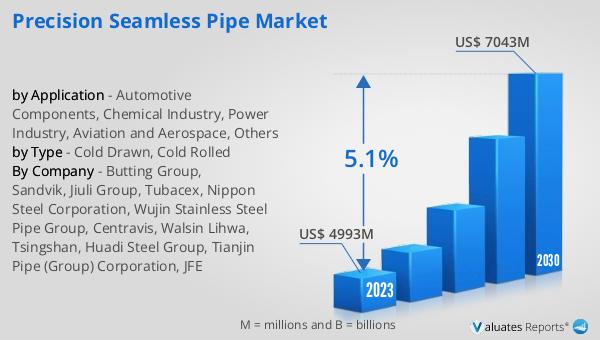

Global Precision Seamless Pipe Market Outlook:

The outlook for the Global Precision Seamless Pipe Market indicates a promising growth trajectory, with projections suggesting an increase from US$ 5,226 million in 2024 to US$ 7,366 million by 2031. This growth, at a compound annual growth rate (CAGR) of 5.1% from 2025 to 2031, is driven by the critical role that precision seamless pipes play in various product segments and their diverse end-use applications. Industries such as automotive, chemical, power, and aerospace are increasingly relying on these pipes for their high strength, durability, and precision, which are essential for ensuring the reliability and efficiency of critical systems and processes. However, the market is not without its challenges. Evolving U.S. tariff policies are introducing trade cost volatility and supply chain uncertainty, which could impact the market dynamics. These policies may affect the pricing and availability of raw materials, as well as the competitiveness of manufacturers in the global market. Despite these challenges, the demand for precision seamless pipes is expected to remain strong, driven by the need for high-quality materials that meet the stringent requirements of modern engineering and manufacturing processes. As manufacturers continue to invest in advanced technologies and equipment to enhance the efficiency and quality of their products, the Global Precision Seamless Pipe Market is well-positioned to capitalize on the growing demand and expand its reach across various industries.

| Report Metric | Details |

| Report Name | Precision Seamless Pipe Market |

| Accounted market size in 2024 | US$ 5226 million |

| Forecasted market size in 2031 | US$ 7366 million |

| CAGR | 5.1% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Butting Group, Sandvik, Jiuli Group, Tubacex, Nippon Steel Corporation, Wujin Stainless Steel Pipe Group, Centravis, Walsin Lihwa, Tsingshan, Huadi Steel Group, Tianjin Pipe (Group) Corporation, JFE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |