What is Global Oxygen Barrier PEX Tubes Market?

The Global Oxygen Barrier PEX Tubes Market refers to the international market for cross-linked polyethylene (PEX) tubes that are specifically designed with an oxygen barrier. These tubes are primarily used in plumbing and heating systems to prevent oxygen from permeating through the tubing walls, which can lead to corrosion of metal components in the system. The oxygen barrier is typically made from an ethylene vinyl alcohol (EVOH) layer, which is co-extruded with the PEX material. This market is driven by the increasing demand for durable and efficient plumbing solutions in both residential and commercial sectors. The tubes are favored for their flexibility, ease of installation, and resistance to scale and chlorine, making them a popular choice for modern construction projects. As the construction industry continues to grow globally, the demand for oxygen barrier PEX tubes is expected to rise, supported by advancements in manufacturing technologies and the development of new applications. The market is also influenced by regulatory standards and environmental considerations, as these tubes offer a more sustainable option compared to traditional metal pipes. Overall, the Global Oxygen Barrier PEX Tubes Market is poised for steady growth as it adapts to changing consumer needs and technological innovations.

PEX-A, PEX-B, Others in the Global Oxygen Barrier PEX Tubes Market:

PEX-A, PEX-B, and other types of PEX tubes play a significant role in the Global Oxygen Barrier PEX Tubes Market, each offering unique characteristics and benefits. PEX-A is known for its superior flexibility and thermal memory, which allows it to be easily bent and shaped without the need for fittings. This type of PEX is produced using the Engel method, which involves cross-linking the polyethylene molecules during the extrusion process. The result is a highly flexible tube that can withstand extreme temperatures and pressures, making it ideal for radiant heating systems and plumbing applications where tight bends are required. PEX-A's flexibility also reduces the risk of kinking, which can compromise the integrity of the tubing. On the other hand, PEX-B is manufactured using the Silane method, which involves cross-linking the polyethylene molecules after the extrusion process. This method results in a slightly stiffer tube compared to PEX-A, but it offers excellent resistance to chlorine and oxidative degradation. PEX-B is often used in potable water systems and is favored for its cost-effectiveness and durability. It is also less prone to creep, which is the tendency of a material to deform under constant stress. Other types of PEX, such as PEX-C, are produced using the electron beam method, which involves cross-linking the polyethylene molecules using high-energy electrons. PEX-C is known for its uniform cross-linking and resistance to cracking, making it suitable for a wide range of applications. While PEX-C is less flexible than PEX-A, it offers a good balance of performance and cost, making it a popular choice for both residential and commercial projects. Each type of PEX tube has its own set of advantages and limitations, and the choice of which to use often depends on the specific requirements of the project. Factors such as installation environment, budget, and regulatory compliance all play a role in determining the most suitable type of PEX for a given application. As the Global Oxygen Barrier PEX Tubes Market continues to evolve, manufacturers are investing in research and development to enhance the performance and versatility of these products, ensuring they meet the diverse needs of consumers worldwide.

Residential, Commercial, Others in the Global Oxygen Barrier PEX Tubes Market:

The usage of Global Oxygen Barrier PEX Tubes Market spans across various sectors, including residential, commercial, and other specialized applications. In residential settings, these tubes are commonly used for plumbing and heating systems due to their flexibility, durability, and resistance to corrosion. Homeowners and builders prefer oxygen barrier PEX tubes for their ability to prevent oxygen from entering the system, which can lead to the corrosion of metal components such as boilers and radiators. This makes them an ideal choice for radiant floor heating systems, where maintaining the integrity of the system is crucial for efficient heat distribution. Additionally, the ease of installation and reduced need for fittings make PEX tubes a cost-effective solution for residential plumbing projects. In commercial applications, oxygen barrier PEX tubes are used in a variety of settings, including office buildings, hotels, and healthcare facilities. The tubes' ability to withstand high temperatures and pressures makes them suitable for large-scale heating and cooling systems, where reliability and performance are paramount. In these environments, the use of oxygen barrier PEX tubes helps to ensure the longevity of the system by preventing corrosion and reducing maintenance costs. Furthermore, the tubes' flexibility allows for easy installation in complex layouts, making them a preferred choice for retrofitting existing systems or designing new ones. Beyond residential and commercial uses, oxygen barrier PEX tubes are also employed in other specialized applications, such as snow melting systems and geothermal heating. In snow melting systems, the tubes are embedded in driveways, walkways, and other outdoor surfaces to provide efficient and reliable snow and ice removal. The oxygen barrier prevents corrosion of the metal components in the system, ensuring its longevity and effectiveness. In geothermal heating applications, oxygen barrier PEX tubes are used to transfer heat from the ground to the building, providing an energy-efficient and environmentally friendly heating solution. The tubes' resistance to chemical degradation and ability to withstand extreme temperatures make them well-suited for these demanding applications. Overall, the versatility and performance of oxygen barrier PEX tubes make them a valuable asset in a wide range of industries, contributing to their growing popularity in the global market.

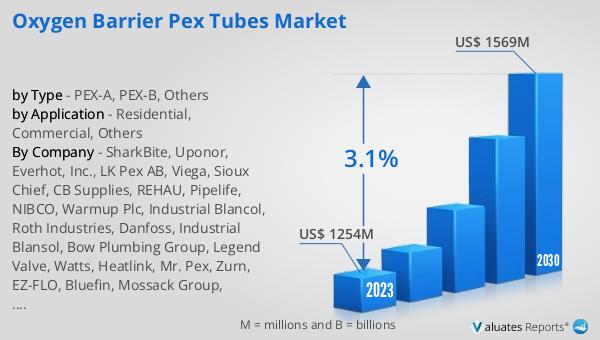

Global Oxygen Barrier PEX Tubes Market Outlook:

The global market for Oxygen Barrier PEX Tubes is anticipated to expand from $1,305 million in 2024 to $1,613 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.1% from 2025 to 2031. This growth is largely driven by key product segments and a variety of end-use applications that continue to evolve and expand. As industries and consumers increasingly recognize the benefits of these tubes, such as their durability, flexibility, and resistance to corrosion, demand is expected to rise. However, the market is not without its challenges. Changing tariff policies in the United States introduce a level of volatility in trade costs and create uncertainty within the supply chain. These factors can impact the pricing and availability of raw materials, potentially affecting the overall market dynamics. Despite these challenges, the market's growth prospects remain positive, supported by ongoing technological advancements and the development of new applications. Manufacturers are focusing on innovation to enhance the performance and versatility of oxygen barrier PEX tubes, ensuring they meet the diverse needs of consumers worldwide. As the market continues to evolve, stakeholders must navigate these complexities to capitalize on the opportunities presented by this growing industry.

| Report Metric | Details |

| Report Name | Oxygen Barrier PEX Tubes Market |

| Accounted market size in 2024 | US$ 1305 million |

| Forecasted market size in 2031 | US$ 1613 million |

| CAGR | 3.1% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | SharkBite, Uponor, Everhot, Inc., LK Pex AB, Viega, Sioux Chief, CB Supplies, REHAU, Pipelife, NIBCO, Warmup Plc, Industrial Blancol, Roth Industries, Danfoss, Industrial Blansol, Bow Plumbing Group, Legend Valve, Watts, Heatlink, Mr. Pex, Zurn, EZ-FLO, Bluefin, Mossack Group, Everflow, Rifeng, Zhuji Fengfan Piping, Palconn |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |