What is Global Composite Tension Insulator Market?

The Global Composite Tension Insulator Market is a specialized segment within the broader electrical insulator industry, focusing on the development and distribution of composite tension insulators. These insulators are crucial components in electrical systems, providing support and insulation for overhead power lines. Unlike traditional porcelain or glass insulators, composite tension insulators are made from advanced materials such as fiberglass-reinforced polymers, which offer superior mechanical strength and resistance to environmental factors like pollution, moisture, and temperature fluctuations. This makes them particularly suitable for use in harsh environments and high-voltage applications. The market for these insulators is driven by the growing demand for reliable and efficient power transmission and distribution systems, especially in developing regions where infrastructure development is a priority. Additionally, the shift towards renewable energy sources and the need for upgrading aging power grids in developed countries further fuel the demand for composite tension insulators. As a result, manufacturers are investing in research and development to enhance the performance and durability of these insulators, ensuring they meet the evolving needs of the power and energy sector.

E-glass FRP Rod, ECR-glass FRP Rod, Aramid-reinforced Hybrid Rod in the Global Composite Tension Insulator Market:

In the realm of the Global Composite Tension Insulator Market, several advanced materials play a pivotal role in enhancing the performance and reliability of insulators. Among these, E-glass FRP (Fiber Reinforced Polymer) Rods are widely used due to their excellent mechanical properties and cost-effectiveness. E-glass, a type of fiberglass, is known for its high strength-to-weight ratio, making it ideal for applications where weight is a critical factor. These rods provide excellent electrical insulation and are resistant to environmental degradation, ensuring long-term performance in outdoor applications. ECR-glass FRP Rods, on the other hand, are an advanced variant of E-glass, offering enhanced resistance to corrosion. This makes them particularly suitable for use in coastal or industrial areas where exposure to corrosive elements is a concern. The improved durability of ECR-glass rods translates to reduced maintenance costs and longer service life, making them a preferred choice for many utility companies. Aramid-reinforced Hybrid Rods represent another innovative material in the composite tension insulator market. Aramid fibers, known for their exceptional strength and heat resistance, are combined with other materials to create hybrid rods that offer superior mechanical performance. These rods are particularly beneficial in high-stress applications, such as high-voltage transmission lines, where they provide enhanced tensile strength and resistance to mechanical fatigue. The use of aramid-reinforced rods also contributes to the overall safety and reliability of power transmission systems, as they are less prone to failure under extreme conditions. The development and adoption of these advanced materials are driven by the need for more efficient and reliable power transmission solutions. As the demand for electricity continues to grow globally, the importance of robust and durable insulators becomes increasingly apparent. Manufacturers are continually exploring new material combinations and manufacturing techniques to improve the performance of composite tension insulators, ensuring they can withstand the challenges posed by modern power systems. This focus on innovation is crucial for meeting the evolving needs of the power and energy sector, as well as for supporting the transition to more sustainable and resilient energy infrastructures.

Power & Energy, Railway Network, Industrial Plant, Others in the Global Composite Tension Insulator Market:

The Global Composite Tension Insulator Market finds extensive applications across various sectors, including Power & Energy, Railway Network, Industrial Plant, and others. In the Power & Energy sector, composite tension insulators are essential for the efficient transmission and distribution of electricity. They are used in overhead power lines to provide mechanical support and electrical insulation, ensuring the safe and reliable delivery of electricity from power plants to end-users. The superior performance of composite insulators, particularly in terms of mechanical strength and resistance to environmental factors, makes them ideal for use in high-voltage transmission lines and in regions with harsh climatic conditions. In the Railway Network sector, composite tension insulators are used in electrified rail systems to support and insulate overhead catenary wires. These insulators play a crucial role in ensuring the safe and efficient operation of electric trains, providing the necessary electrical insulation and mechanical support for the catenary system. The lightweight and durable nature of composite insulators make them particularly suitable for use in railway applications, where weight and reliability are critical considerations. In Industrial Plants, composite tension insulators are used in various applications, including the insulation of electrical equipment and the support of overhead power lines within the plant. The use of composite insulators in industrial settings is driven by their ability to withstand harsh environmental conditions, such as exposure to chemicals, high temperatures, and mechanical stress. This ensures the reliable operation of electrical systems within the plant, minimizing downtime and maintenance costs. Beyond these specific sectors, composite tension insulators are also used in other applications, such as in telecommunications and renewable energy systems. In telecommunications, they are used to support and insulate overhead cables, ensuring the reliable transmission of data and signals. In renewable energy systems, such as wind and solar power installations, composite insulators are used to support and insulate electrical connections, ensuring the efficient and reliable delivery of electricity generated from renewable sources. The versatility and superior performance of composite tension insulators make them an essential component in a wide range of applications, supporting the safe and efficient operation of electrical systems across various sectors.

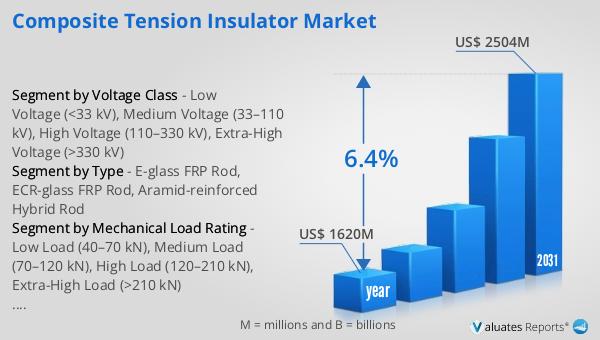

Global Composite Tension Insulator Market Outlook:

The global market for Composite Tension Insulators was valued at $1,620 million in 2024 and is anticipated to expand to a revised size of $2,504 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.4% over the forecast period. This growth trajectory underscores the increasing demand for composite tension insulators, driven by the need for more reliable and efficient power transmission and distribution systems. The market's expansion is fueled by several factors, including the ongoing development of infrastructure in emerging economies and the modernization of aging power grids in developed regions. As countries continue to invest in upgrading their electrical infrastructure to meet the growing demand for electricity, the need for advanced insulators that can withstand harsh environmental conditions and provide superior mechanical performance becomes increasingly critical. Additionally, the shift towards renewable energy sources and the integration of these sources into existing power grids further drive the demand for composite tension insulators. The market's growth is also supported by advancements in material science and manufacturing technologies, which have led to the development of more durable and efficient insulators. As a result, manufacturers are focusing on innovation and product development to meet the evolving needs of the power and energy sector, ensuring the continued growth and success of the Global Composite Tension Insulator Market.

| Report Metric | Details |

| Report Name | Composite Tension Insulator Market |

| Accounted market size in year | US$ 1620 million |

| Forecasted market size in 2031 | US$ 2504 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Mechanical Load Rating |

|

| Segment by Voltage Class |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hitachi Energy (Switzerland), Siemens Energy (Germany), Reinhausen (Germany), SAVER S.p.A. (Italy), Lapp Insulators (USA), PPC Insulators (Austria), NGK Insulators (Japan), Hubbell Power Systems (USA), MacLean Power Systems (USA), TE Connectivity (Switzerland), Aditya Birla Insulators (India), Modern Insulators (India), Spark Insulators (India), Yamuna Power & Infrastructure (India), Wuhan Line Power Transmission Equipment (China), L&R Electric Group (China), Nooa Electric (China), Guowang Composite Insulators (China), Jiangxi Johnson Electric (China), CTC Power Equipment (Taiwan) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |