What is Global Aerospace Carbon Fibers Market?

The Global Aerospace Carbon Fibers Market is a dynamic and rapidly evolving sector that plays a crucial role in the aerospace industry. Carbon fibers are lightweight, high-strength materials that are increasingly being used in the production of aircraft components. These fibers are known for their exceptional strength-to-weight ratio, which makes them ideal for applications where reducing weight is critical, such as in the aerospace sector. The market for aerospace carbon fibers is driven by the growing demand for fuel-efficient aircraft, as lighter materials contribute to lower fuel consumption and reduced emissions. Additionally, advancements in carbon fiber technology have led to improved performance and cost-effectiveness, further boosting their adoption in the aerospace industry. The market is characterized by a diverse range of applications, including commercial aviation, military aircraft, and unmanned aerial vehicles (UAVs), each with its unique set of requirements and challenges. As the aerospace industry continues to expand and innovate, the demand for high-performance materials like carbon fibers is expected to grow, making the Global Aerospace Carbon Fibers Market a key area of focus for manufacturers and researchers alike.

Regular Tow, Large Tow in the Global Aerospace Carbon Fibers Market:

In the Global Aerospace Carbon Fibers Market, carbon fibers are categorized into two main types based on their tow size: Regular Tow and Large Tow. Regular Tow carbon fibers typically consist of 1,000 to 24,000 filaments per tow. These fibers are known for their high tensile strength and are commonly used in applications where precision and performance are paramount. Regular Tow carbon fibers are often employed in the production of primary aircraft structures, such as wings and fuselages, where their superior mechanical properties contribute to the overall strength and durability of the aircraft. The uniformity and consistency of Regular Tow fibers make them ideal for applications that require high-quality finishes and intricate designs. On the other hand, Large Tow carbon fibers consist of more than 24,000 filaments per tow. These fibers are generally more cost-effective than Regular Tow fibers and are used in applications where cost considerations are a priority. Large Tow carbon fibers are often utilized in secondary structures and components, such as interior panels and non-load-bearing parts, where the emphasis is on reducing costs without compromising on performance. The choice between Regular Tow and Large Tow carbon fibers depends on various factors, including the specific requirements of the application, budget constraints, and desired performance characteristics. In the aerospace industry, the selection of carbon fiber type is a critical decision that can significantly impact the overall performance and efficiency of the aircraft. As the demand for lightweight and high-performance materials continues to grow, manufacturers are increasingly exploring innovative ways to optimize the use of both Regular Tow and Large Tow carbon fibers in aerospace applications. This involves not only improving the properties of the fibers themselves but also developing advanced manufacturing techniques that enhance their integration into complex aerospace structures. The ongoing research and development efforts in this field are expected to lead to new breakthroughs and innovations, further expanding the potential applications of carbon fibers in the aerospace industry. As a result, the Global Aerospace Carbon Fibers Market is poised for significant growth, driven by the increasing demand for advanced materials that can meet the evolving needs of the aerospace sector.

Commercial, Military, UAVs in the Global Aerospace Carbon Fibers Market:

The usage of Global Aerospace Carbon Fibers Market in commercial, military, and UAV applications highlights the versatility and importance of carbon fibers in the aerospace industry. In commercial aviation, carbon fibers are primarily used to reduce the weight of aircraft, thereby improving fuel efficiency and reducing operational costs. The use of carbon fibers in the construction of aircraft components such as wings, fuselages, and tail sections has become increasingly common, as airlines seek to enhance the performance and sustainability of their fleets. The lightweight nature of carbon fibers allows for greater payload capacity and longer flight ranges, making them an attractive option for commercial airlines. In the military sector, carbon fibers are used to enhance the performance and capabilities of military aircraft. The high strength-to-weight ratio of carbon fibers allows for the development of advanced aircraft that can achieve higher speeds and greater maneuverability. Additionally, carbon fibers contribute to the stealth capabilities of military aircraft by reducing their radar cross-section. This makes them an essential component in the design and production of modern fighter jets and other military aircraft. In the realm of unmanned aerial vehicles (UAVs), carbon fibers play a crucial role in the development of lightweight and efficient drones. The use of carbon fibers in UAV construction allows for longer flight times and increased payload capacity, which are critical factors in the performance of drones. As the demand for UAVs continues to grow in various sectors, including surveillance, agriculture, and logistics, the use of carbon fibers is expected to expand, further driving the growth of the Global Aerospace Carbon Fibers Market. Overall, the diverse applications of carbon fibers in commercial, military, and UAV sectors underscore their significance in the aerospace industry and highlight the ongoing efforts to leverage their unique properties to achieve greater efficiency and performance.

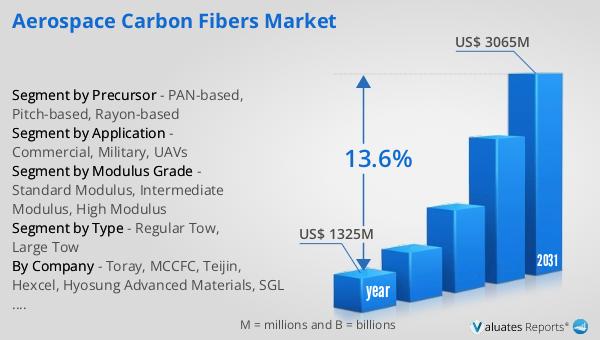

Global Aerospace Carbon Fibers Market Outlook:

The global market for Aerospace Carbon Fibers was valued at $1,325 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $3,065 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 13.6% over the forecast period. The increasing demand for lightweight and high-performance materials in the aerospace industry is a key driver of this growth. As airlines and aircraft manufacturers strive to improve fuel efficiency and reduce emissions, the adoption of carbon fibers is expected to rise. The market's expansion is also supported by advancements in carbon fiber technology, which have led to improved performance and cost-effectiveness. Additionally, the growing demand for military aircraft and UAVs further contributes to the market's growth, as these sectors increasingly rely on carbon fibers to enhance the performance and capabilities of their aircraft. The projected growth of the Global Aerospace Carbon Fibers Market reflects the ongoing efforts to leverage advanced materials to meet the evolving needs of the aerospace industry. As the market continues to expand, manufacturers and researchers are expected to focus on developing innovative solutions that optimize the use of carbon fibers in aerospace applications, further driving the market's growth and development.

| Report Metric | Details |

| Report Name | Aerospace Carbon Fibers Market |

| Accounted market size in year | US$ 1325 million |

| Forecasted market size in 2031 | US$ 3065 million |

| CAGR | 13.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Precursor |

|

| Segment by Modulus Grade |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toray, MCCFC, Teijin, Hexcel, Hyosung Advanced Materials, SGL Carbon, Formosa Plastics, DowAksa, Syensqo, UMATEX, Taekwang Industrial, Zhongfu Shenying, Jilin Chemical Fiber, Baowu Carbon, Weihai Guangwei Composites, Sinofibers Technology, Jiangsu Hengshen, Newtech Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |