What is Global Riveting Leadframe Market?

The Global Riveting Leadframe Market is a specialized segment within the broader electronics and semiconductor industry, focusing on the production and distribution of leadframes used in riveting applications. Leadframes are essential components in semiconductor devices, serving as the metal structures that support and connect the semiconductor chip to the external circuitry. In the context of riveting, these leadframes are designed to be robust and durable, ensuring that they can withstand the mechanical stresses involved in the riveting process. The market for these leadframes is driven by the increasing demand for miniaturized and high-performance electronic devices, which require reliable and efficient packaging solutions. As technology advances, the need for more sophisticated leadframe designs has grown, leading to innovations in materials and manufacturing processes. The global market is characterized by a diverse range of players, from large multinational corporations to smaller specialized firms, all competing to provide the most advanced and cost-effective solutions. With the continuous growth in electronics and semiconductor industries, the Global Riveting Leadframe Market is poised for significant expansion, driven by technological advancements and increasing consumer demand for electronic devices.

Single-Layer, Multi-layer (Riveted Stack-Up) in the Global Riveting Leadframe Market:

In the Global Riveting Leadframe Market, the distinction between single-layer and multi-layer (riveted stack-up) leadframes is crucial for understanding the different applications and benefits each type offers. Single-layer leadframes are typically used in simpler electronic devices where the requirements for electrical connectivity and mechanical support are less complex. These leadframes consist of a single metal layer, usually made from materials like copper or a copper alloy, which provides a straightforward and cost-effective solution for basic semiconductor packaging needs. The simplicity of single-layer leadframes makes them ideal for applications where cost is a significant consideration, and the performance requirements are not as demanding. On the other hand, multi-layer leadframes, also known as riveted stack-up leadframes, are designed for more complex and high-performance applications. These leadframes consist of multiple metal layers that are riveted together, allowing for greater flexibility in design and enhanced electrical and thermal performance. The additional layers in a multi-layer leadframe can accommodate more complex circuitry and provide better heat dissipation, which is essential for high-power and high-frequency applications. The riveted stack-up design also allows for more intricate and compact packaging solutions, which are increasingly in demand as electronic devices continue to shrink in size while increasing in functionality. The choice between single-layer and multi-layer leadframes depends largely on the specific requirements of the application, including factors such as electrical performance, thermal management, mechanical strength, and cost. In many cases, the decision will also be influenced by the overall design and manufacturing strategy of the device, as well as the availability of materials and manufacturing capabilities. As the Global Riveting Leadframe Market continues to evolve, manufacturers are constantly exploring new materials and technologies to enhance the performance and reduce the cost of both single-layer and multi-layer leadframes. This ongoing innovation is driven by the need to meet the ever-increasing demands of the electronics and semiconductor industries, which require more efficient, reliable, and cost-effective packaging solutions. The development of new materials, such as advanced copper alloys and composite materials, is one area of focus, as these materials can offer improved electrical and thermal properties compared to traditional options. Additionally, advancements in manufacturing techniques, such as precision stamping and etching, are enabling the production of more complex and precise leadframe designs, further enhancing their performance and reliability. As a result, both single-layer and multi-layer leadframes are expected to play a critical role in the future of semiconductor packaging, providing the necessary support and connectivity for the next generation of electronic devices.

Electronics and Semiconductors, Automotive, Communications, Other in the Global Riveting Leadframe Market:

The Global Riveting Leadframe Market finds its applications across various sectors, including electronics and semiconductors, automotive, communications, and other industries. In the electronics and semiconductor sector, leadframes are integral to the packaging of semiconductor devices, providing the necessary support and electrical connections between the chip and the external circuitry. As electronic devices become more compact and complex, the demand for advanced leadframe solutions has increased, driving innovation in materials and manufacturing processes. In the automotive industry, leadframes are used in a variety of applications, including engine control units, sensors, and other electronic components that require reliable and durable connections. The harsh operating conditions in automotive environments, such as high temperatures and vibrations, necessitate the use of robust leadframe designs that can withstand these challenges. In the communications sector, leadframes are used in devices such as smartphones, tablets, and other wireless communication devices, where they play a critical role in ensuring reliable signal transmission and reception. The increasing demand for high-speed and high-frequency communication devices has led to the development of more sophisticated leadframe designs that can support these advanced technologies. Beyond these primary sectors, leadframes are also used in a variety of other applications, including consumer electronics, industrial equipment, and medical devices. In each of these areas, the specific requirements for leadframe performance and reliability can vary significantly, driving the need for customized solutions that can meet the unique demands of each application. As the Global Riveting Leadframe Market continues to grow, manufacturers are focusing on developing new materials and technologies that can enhance the performance and reduce the cost of leadframes across all these sectors. This ongoing innovation is essential to meet the evolving needs of the market and ensure the continued success of leadframe solutions in a wide range of applications.

Global Riveting Leadframe Market Outlook:

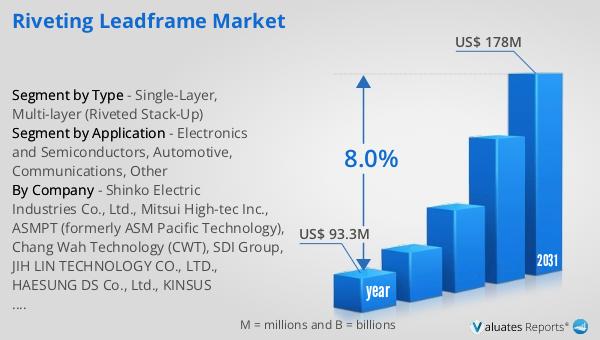

In 2024, the global market for Riveting Leadframe was valued at approximately $93.3 million. Looking ahead, this market is anticipated to expand significantly, reaching an estimated size of $178 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.0% over the forecast period. The robust growth of the Riveting Leadframe Market can be attributed to several factors, including the increasing demand for advanced electronic devices and the continuous advancements in semiconductor technology. As consumers and industries alike seek more efficient and compact electronic solutions, the need for reliable and high-performance leadframes has become more pronounced. This demand is further fueled by the rapid pace of technological innovation, which is driving the development of new materials and manufacturing processes that enhance the performance and reduce the cost of leadframes. Additionally, the expanding applications of leadframes across various sectors, such as automotive, communications, and consumer electronics, are contributing to the market's growth. As these industries continue to evolve and adopt new technologies, the demand for advanced leadframe solutions is expected to rise, supporting the market's expansion. Overall, the Global Riveting Leadframe Market is poised for significant growth in the coming years, driven by the increasing demand for high-performance electronic devices and the continuous advancements in semiconductor technology.

| Report Metric | Details |

| Report Name | Riveting Leadframe Market |

| Accounted market size in year | US$ 93.3 million |

| Forecasted market size in 2031 | US$ 178 million |

| CAGR | 8.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shinko Electric Industries Co., Ltd., Mitsui High-tec Inc., ASMPT (formerly ASM Pacific Technology), Chang Wah Technology (CWT), SDI Group, JIH LIN TECHNOLOGY CO., LTD., HAESUNG DS Co., Ltd., KINSUS Interconnect Technology, Hualong Group, QPL International Holdings, Jiangsu Huafeng Technology Co., Ltd., Possehl Group (Lübeck Leadframes), Dynacraft Industries (a part of Microchip Technology), Unimicron, Fusheng Electronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |