What is Global Polyester–Polyether Block Copolymers Market?

The Global Polyester–Polyether Block Copolymers Market is a dynamic and evolving sector within the broader field of polymer science. These copolymers are unique materials that combine the properties of both polyester and polyether segments, resulting in a versatile product with a wide range of applications. Polyester segments typically provide strength, durability, and resistance to environmental factors, while polyether segments offer flexibility and elasticity. This combination makes polyester–polyether block copolymers highly desirable in industries that require materials with both toughness and flexibility. The market for these copolymers is driven by their increasing use in various sectors such as automotive, packaging, healthcare, and consumer electronics, among others. As industries continue to seek materials that offer enhanced performance and sustainability, the demand for polyester–polyether block copolymers is expected to grow. These copolymers are also valued for their ability to be tailored to specific applications, allowing manufacturers to meet the precise needs of their customers. Overall, the Global Polyester–Polyether Block Copolymers Market represents a significant area of growth and innovation within the polymer industry, with ongoing research and development efforts aimed at expanding their applications and improving their properties.

Linear Block Copolymers, Multi-block Copolymers, Graft Copolymers in the Global Polyester–Polyether Block Copolymers Market:

Linear block copolymers, multi-block copolymers, and graft copolymers are three distinct types of copolymers that play a crucial role in the Global Polyester–Polyether Block Copolymers Market. Linear block copolymers consist of two or more distinct polymer blocks arranged in a linear sequence. This structure allows for the combination of different polymer properties in a single material, making them highly versatile. In the context of polyester–polyether block copolymers, the linear arrangement enables the material to exhibit both the strength and durability of polyester and the flexibility and elasticity of polyether. This makes linear block copolymers ideal for applications that require a balance of toughness and flexibility, such as in automotive parts and industrial components. Multi-block copolymers, on the other hand, consist of multiple repeating sequences of different polymer blocks. This structure provides even greater versatility, as it allows for the fine-tuning of material properties by varying the length and composition of each block. In the Global Polyester–Polyether Block Copolymers Market, multi-block copolymers are used in applications that require specific performance characteristics, such as high impact resistance or enhanced thermal stability. The ability to customize the properties of multi-block copolymers makes them highly valuable in industries such as healthcare and consumer electronics, where precise material performance is critical. Graft copolymers are another important type of copolymer in this market. They consist of a main polymer backbone with side chains, or "grafts," of a different polymer attached to it. This unique structure allows for the combination of properties from both the backbone and the grafts, resulting in materials with enhanced performance characteristics. In the case of polyester–polyether block copolymers, graft copolymers can provide improved adhesion, impact resistance, and chemical resistance. These properties make graft copolymers suitable for use in demanding applications such as sporting goods and packaging, where materials must withstand harsh conditions and maintain their integrity. Overall, the diversity of copolymer structures within the Global Polyester–Polyether Block Copolymers Market allows for a wide range of applications and performance characteristics, making them an essential component of modern material science.

Automotive, Packaging, Healthcare, Consumer Electronics, Industrial, Sporting Goods, Others in the Global Polyester–Polyether Block Copolymers Market:

The usage of Global Polyester–Polyether Block Copolymers Market spans across various industries, each benefiting from the unique properties of these materials. In the automotive industry, polyester–polyether block copolymers are used to manufacture components that require a combination of strength, flexibility, and resistance to environmental factors. These copolymers are ideal for producing parts such as seals, gaskets, and hoses, which must withstand harsh conditions while maintaining their performance. In the packaging industry, polyester–polyether block copolymers are valued for their durability and flexibility, making them suitable for creating packaging materials that protect products during transportation and storage. Their ability to provide a strong barrier against moisture and chemicals also makes them an excellent choice for food and beverage packaging. In the healthcare sector, these copolymers are used to produce medical devices and equipment that require biocompatibility and sterilization resistance. Their flexibility and strength make them ideal for applications such as tubing, catheters, and surgical instruments. In consumer electronics, polyester–polyether block copolymers are used to manufacture components that require precision and durability, such as connectors, cables, and protective casings. Their ability to withstand high temperatures and mechanical stress makes them suitable for use in electronic devices that are subject to frequent handling and environmental exposure. In the industrial sector, these copolymers are used to produce components that require high performance and reliability, such as conveyor belts, seals, and gaskets. Their resistance to wear and tear, as well as their ability to maintain performance under extreme conditions, make them an essential material for industrial applications. In the sporting goods industry, polyester–polyether block copolymers are used to manufacture equipment that requires a balance of strength and flexibility, such as protective gear, footwear, and athletic apparel. Their ability to provide impact resistance and comfort makes them a popular choice for sports equipment manufacturers. Finally, in other industries, polyester–polyether block copolymers are used in a variety of applications that require materials with specific performance characteristics, such as adhesives, coatings, and textiles. Overall, the versatility and performance of polyester–polyether block copolymers make them a valuable material across a wide range of industries.

Global Polyester–Polyether Block Copolymers Market Outlook:

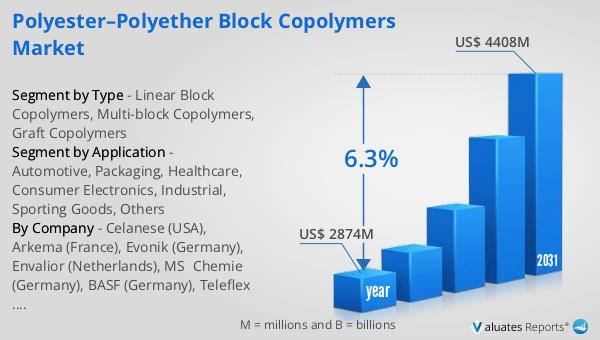

The global market for Polyester–Polyether Block Copolymers was valued at $2,874 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $4,408 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.3% during the forecast period. This upward trend reflects the increasing demand for these versatile materials across various industries. The ability of polyester–polyether block copolymers to combine the desirable properties of both polyester and polyether segments makes them highly sought after in sectors such as automotive, packaging, healthcare, and consumer electronics. As industries continue to innovate and seek materials that offer enhanced performance and sustainability, the demand for these copolymers is expected to rise. The projected growth of the market also highlights the ongoing research and development efforts aimed at expanding the applications and improving the properties of polyester–polyether block copolymers. This market outlook underscores the importance of these materials in modern material science and their potential to drive innovation across multiple industries.

| Report Metric | Details |

| Report Name | Polyester–Polyether Block Copolymers Market |

| Accounted market size in year | US$ 2874 million |

| Forecasted market size in 2031 | US$ 4408 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Celanese (USA), Arkema (France), Evonik (Germany), Envalior (Netherlands), MS‑Chemie (Germany), BASF (Germany), Teleflex (USA), Zeus (USA), Zotefoams (UK), Lubrizol (USA), Saint‑Gobain (France), RTP Company (USA), TPE Solutions (USA), SK Chemicals (South Korea), AGC Chemicals (Japan), Polyplastics (Japan), Poliya (Turkey), Eastman Chemical (USA), Bostik Findley (France), Toyobo (Japan), Covestro (Germany), EMS Chemie (Switzerland), Macroocean (China), Henkel (Germany), INEOS (UK) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |