What is Global Industrial Pilot Hole Drill Bits Market?

The Global Industrial Pilot Hole Drill Bits Market is a specialized segment within the broader industrial tools industry, focusing on drill bits specifically designed for creating pilot holes. These pilot holes are essential in various applications as they guide larger drill bits, ensuring precision and reducing the risk of material damage. The market encompasses a wide range of drill bits made from different materials, each catering to specific industrial needs. The demand for these drill bits is driven by their critical role in enhancing the efficiency and accuracy of drilling operations across multiple sectors. Industries such as construction, metalworking, aerospace, and automotive heavily rely on these tools for their operations. The market is characterized by continuous innovation, with manufacturers striving to develop drill bits that offer superior durability, precision, and performance. As industries evolve and demand more efficient tools, the Global Industrial Pilot Hole Drill Bits Market is expected to grow, driven by technological advancements and the increasing need for precision in industrial applications. The market's growth is also influenced by the expansion of industrial activities worldwide, necessitating reliable and efficient drilling solutions.

High-Speed Steel (HSS), Cobalt, Carbide-Tipped, Titanium Coated in the Global Industrial Pilot Hole Drill Bits Market:

High-Speed Steel (HSS), Cobalt, Carbide-Tipped, and Titanium Coated drill bits are pivotal components of the Global Industrial Pilot Hole Drill Bits Market, each offering unique advantages tailored to specific industrial needs. High-Speed Steel (HSS) drill bits are renowned for their versatility and durability. They are made from a combination of steel and other elements, which allows them to withstand high temperatures without losing their hardness. This makes HSS drill bits ideal for general-purpose drilling in materials like wood, plastic, and soft metals. Their affordability and reliability make them a popular choice in various industries, particularly where cost-effectiveness is a priority. Cobalt drill bits, on the other hand, are an enhanced version of HSS bits, containing a higher percentage of cobalt. This addition significantly increases their heat resistance and hardness, making them suitable for drilling into tougher materials such as stainless steel and other hard metals. Cobalt drill bits are favored in industries where precision and durability are crucial, such as aerospace and automotive manufacturing. Carbide-Tipped drill bits are known for their exceptional hardness and ability to retain a sharp edge, even under extreme conditions. They are made by attaching a carbide tip to a steel shank, combining the toughness of steel with the cutting efficiency of carbide. These drill bits are ideal for drilling into hard materials like concrete, masonry, and ceramics, making them indispensable in the construction industry. Their ability to maintain performance over extended periods makes them a cost-effective solution for heavy-duty applications. Titanium Coated drill bits are another important category, featuring a titanium nitride coating that enhances their hardness and reduces friction. This coating not only extends the life of the drill bit but also improves its cutting speed and efficiency. Titanium Coated drill bits are versatile and can be used on a variety of materials, including metal, wood, and plastic. They are particularly valued in applications where speed and precision are essential, such as in the automotive and metalworking industries. Each of these drill bit types plays a crucial role in the Global Industrial Pilot Hole Drill Bits Market, catering to the diverse needs of industries that require reliable and efficient drilling solutions. As technology advances, the development of new materials and coatings continues to enhance the performance and lifespan of these drill bits, driving innovation and growth within the market.

Metalworking, Construction, Aerospace, Automotive, Others in the Global Industrial Pilot Hole Drill Bits Market:

The usage of Global Industrial Pilot Hole Drill Bits Market spans several key industries, each with specific requirements and applications. In the metalworking industry, pilot hole drill bits are essential for creating precise holes in metal components. These drill bits ensure accuracy and prevent material wastage, which is crucial in metal fabrication processes. The ability to create clean and accurate pilot holes is vital for tasks such as threading, tapping, and assembling metal parts. In the construction industry, pilot hole drill bits are used extensively for tasks such as installing screws, bolts, and anchors. They provide the necessary guidance for larger drill bits, ensuring that holes are drilled accurately and efficiently. This is particularly important in construction projects where precision and structural integrity are paramount. The aerospace industry relies on pilot hole drill bits for the assembly and maintenance of aircraft components. Given the stringent safety and quality standards in this industry, the use of high-quality drill bits is essential to ensure that all components are securely fastened and aligned. The automotive industry also benefits from the use of pilot hole drill bits, particularly in the manufacturing and assembly of vehicle components. These drill bits help ensure that holes are drilled with precision, which is critical for the proper alignment and functioning of various automotive parts. Additionally, pilot hole drill bits are used in other industries such as woodworking, where they help create accurate holes for screws and dowels, and in the electronics industry, where they are used for assembling circuit boards and other components. The versatility and precision offered by pilot hole drill bits make them indispensable tools across a wide range of applications, driving their demand in the global market.

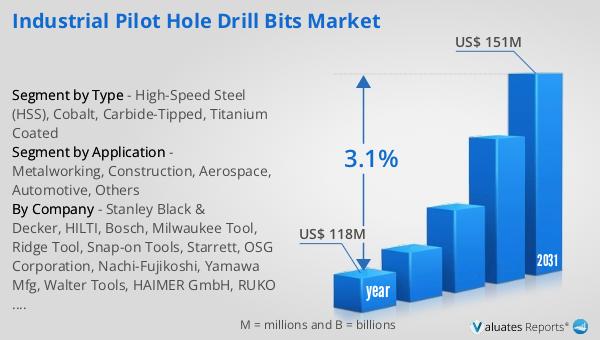

Global Industrial Pilot Hole Drill Bits Market Outlook:

In 2024, the global market for Industrial Pilot Hole Drill Bits was valued at approximately US$ 118 million. This market is anticipated to experience growth over the coming years, with projections indicating that it will reach an estimated size of US$ 151 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 3.1% during the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for precision drilling tools across various industries. As sectors such as construction, metalworking, aerospace, and automotive continue to expand, the need for reliable and efficient pilot hole drill bits becomes increasingly important. These tools play a crucial role in ensuring accuracy and efficiency in drilling operations, which are essential for the successful completion of industrial projects. Additionally, advancements in drill bit technology, such as the development of new materials and coatings, are expected to further drive market growth by enhancing the performance and lifespan of these tools. As a result, the Global Industrial Pilot Hole Drill Bits Market is poised for continued expansion, supported by the growing demand for high-quality drilling solutions in industrial applications.

| Report Metric | Details |

| Report Name | Industrial Pilot Hole Drill Bits Market |

| Accounted market size in year | US$ 118 million |

| Forecasted market size in 2031 | US$ 151 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Stanley Black & Decker, HILTI, Bosch, Milwaukee Tool, Ridge Tool, Snap-on Tools, Starrett, OSG Corporation, Nachi-Fujikoshi, Yamawa Mfg, Walter Tools, HAIMER GmbH, RUKO GmbH, Norseman Drill & Tool, Inc, Zhuzhou Cemented Carbide Cutting Tools |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |