What is Global Crawler Wall Climbing Robot Chassis Market?

The Global Crawler Wall Climbing Robot Chassis Market is a specialized segment within the robotics industry that focuses on the development and deployment of robots capable of climbing vertical surfaces. These robots are equipped with advanced chassis systems that allow them to adhere to and navigate walls, ceilings, and other challenging terrains. The market for these innovative machines is driven by the increasing demand for automation in various industries, including construction, maintenance, and inspection. These robots are particularly valuable in environments that are hazardous or difficult for humans to access, such as high-rise buildings, industrial plants, and ship hulls. The technology behind these robots often involves sophisticated mechanisms for adhesion, such as magnetic or vacuum systems, which enable them to maintain stability and maneuverability on vertical surfaces. As industries continue to seek efficient and safe solutions for tasks that involve working at heights or in confined spaces, the demand for crawler wall climbing robot chassis is expected to grow. This market is characterized by continuous advancements in robotics technology, leading to more versatile and capable machines that can perform a wide range of tasks with precision and reliability.

Magnetic Adsorption, Vacuum Adsorption in the Global Crawler Wall Climbing Robot Chassis Market:

In the realm of the Global Crawler Wall Climbing Robot Chassis Market, two primary adhesion technologies are pivotal: magnetic adsorption and vacuum adsorption. Magnetic adsorption relies on the use of powerful magnets to adhere the robot to ferromagnetic surfaces. This method is particularly effective on steel structures, such as ship hulls and industrial tanks, where the magnetic force can provide a strong and reliable grip. The advantage of magnetic adsorption is its simplicity and effectiveness on metal surfaces, allowing the robot to move smoothly and maintain stability even on vertical or inverted planes. However, its limitation lies in its dependency on the presence of ferromagnetic materials, which restricts its application to specific environments. On the other hand, vacuum adsorption utilizes suction mechanisms to create a vacuum seal between the robot and the surface it is climbing. This technology is more versatile as it can be applied to a wider range of materials, including glass, concrete, and other non-metallic surfaces. Vacuum adsorption systems typically involve the use of suction cups or pads that can conform to the surface texture, ensuring a secure grip. The flexibility of vacuum adsorption makes it suitable for diverse applications, from cleaning skyscraper windows to inspecting concrete structures. However, the effectiveness of vacuum systems can be influenced by surface conditions, such as roughness or the presence of debris, which may affect the seal's integrity. Both magnetic and vacuum adsorption technologies have their unique advantages and challenges, and the choice between them often depends on the specific application requirements. In some cases, hybrid systems that combine both technologies are developed to enhance the robot's adaptability to different surfaces. These hybrid systems can switch between magnetic and vacuum modes, optimizing the robot's performance based on the surface material and environmental conditions. As the Global Crawler Wall Climbing Robot Chassis Market continues to evolve, ongoing research and development efforts are focused on improving the efficiency, reliability, and versatility of these adhesion technologies. Innovations such as advanced sensor integration, AI-driven navigation, and energy-efficient designs are being explored to enhance the capabilities of wall climbing robots, making them more effective tools for industrial and commercial applications.

Ship Cleaning, Industrial Inspection, High-Altitude Work, Others in the Global Crawler Wall Climbing Robot Chassis Market:

The Global Crawler Wall Climbing Robot Chassis Market finds its applications in various sectors, each benefiting from the unique capabilities of these robots. In ship cleaning, these robots are invaluable for maintaining the hulls of large vessels. Traditional methods of cleaning ship hulls are labor-intensive and time-consuming, often requiring divers or scaffolding. Wall climbing robots equipped with magnetic or vacuum adhesion systems can efficiently navigate the curved and vertical surfaces of ship hulls, performing cleaning tasks with precision and speed. This not only reduces the time and cost associated with hull maintenance but also enhances safety by minimizing the need for human intervention in potentially hazardous environments. In the field of industrial inspection, crawler wall climbing robots are used to assess the condition of large structures such as storage tanks, pipelines, and bridges. These robots can be equipped with various sensors and cameras to detect structural anomalies, corrosion, or other defects that may compromise the integrity of the structure. By providing real-time data and high-resolution imagery, these robots enable engineers to make informed decisions about maintenance and repairs, thereby preventing costly failures and extending the lifespan of critical infrastructure. High-altitude work is another area where these robots excel. Tasks such as window cleaning, painting, or facade inspection on skyscrapers and tall buildings pose significant risks to human workers. Wall climbing robots can perform these tasks with greater safety and efficiency, eliminating the need for scaffolding or aerial lifts. Their ability to adhere to and move along vertical surfaces allows them to cover large areas quickly, reducing the time and labor required for high-altitude maintenance work. Beyond these specific applications, the versatility of crawler wall climbing robots opens up possibilities in other areas as well. For instance, they can be used in disaster response scenarios to assess damage in hard-to-reach areas or in the maintenance of wind turbines and solar panels. As technology advances, the potential uses for these robots continue to expand, driven by the need for safer, more efficient, and cost-effective solutions in various industries. The Global Crawler Wall Climbing Robot Chassis Market is poised to play a crucial role in meeting these demands, offering innovative solutions that enhance productivity and safety across multiple sectors.

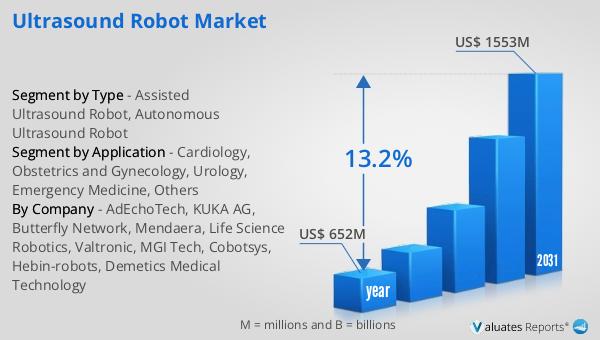

Global Crawler Wall Climbing Robot Chassis Market Outlook:

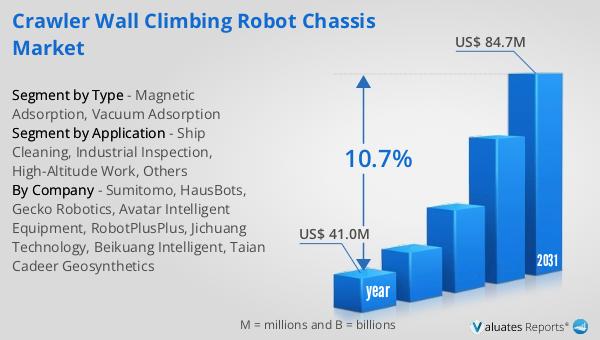

The global market for Crawler Wall Climbing Robot Chassis was valued at $41 million in 2024, with projections indicating a significant growth trajectory. By 2031, the market is expected to reach an estimated size of $84.7 million, reflecting a compound annual growth rate (CAGR) of 10.7% over the forecast period. This robust growth is indicative of the increasing demand for advanced robotic solutions capable of performing tasks in challenging environments. The market's expansion is driven by the need for automation in industries such as construction, maintenance, and inspection, where traditional methods are often labor-intensive, costly, and potentially hazardous. The adoption of crawler wall climbing robots is fueled by their ability to enhance safety and efficiency in various applications, from ship cleaning to high-altitude work. As industries continue to prioritize worker safety and operational efficiency, the demand for these innovative machines is expected to rise. The market's growth is also supported by ongoing advancements in robotics technology, which are leading to the development of more versatile and capable robots. These advancements include improvements in adhesion technologies, sensor integration, and AI-driven navigation systems, all of which contribute to the enhanced performance and reliability of wall climbing robots. As the Global Crawler Wall Climbing Robot Chassis Market continues to evolve, it presents significant opportunities for manufacturers, technology developers, and end-users alike. The market's growth trajectory underscores the importance of continued innovation and investment in this field, as industries seek to leverage the benefits of automation to improve safety, efficiency, and productivity.

| Report Metric | Details |

| Report Name | Crawler Wall Climbing Robot Chassis Market |

| Accounted market size in year | US$ 41.0 million |

| Forecasted market size in 2031 | US$ 84.7 million |

| CAGR | 10.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sumitomo, HausBots, Gecko Robotics, Avatar Intelligent Equipment, RobotPlusPlus, Jichuang Technology, Beikuang Intelligent, Taian Cadeer Geosynthetics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |