What is Global Industrial Ceramic Fiber Blanket Market?

The Global Industrial Ceramic Fiber Blanket Market is a specialized segment within the broader industrial insulation market, focusing on the production and distribution of ceramic fiber blankets. These blankets are made from alumina-silica materials and are known for their excellent thermal insulation properties, lightweight nature, and resistance to thermal shock. They are widely used in industries that require high-temperature insulation solutions, such as steel, ceramics, petrochemicals, and power generation. The market is driven by the increasing demand for energy-efficient solutions and the need to reduce energy consumption in industrial processes. Additionally, the growing emphasis on sustainability and environmental regulations has led to the adoption of ceramic fiber blankets as they help in reducing greenhouse gas emissions by improving energy efficiency. The market is characterized by a diverse range of products, including conventional ceramic fiber blankets, high-purity ceramic fiber blankets, and others, each catering to specific industrial needs. The global reach of this market is expanding, with significant growth opportunities in emerging economies where industrialization is on the rise. Overall, the Global Industrial Ceramic Fiber Blanket Market plays a crucial role in enhancing the efficiency and sustainability of industrial operations worldwide.

Conventional Ceramic Fiber Blanket, High Purity Ceramic Fiber Blanket, Others in the Global Industrial Ceramic Fiber Blanket Market:

Conventional Ceramic Fiber Blankets are the most commonly used type within the Global Industrial Ceramic Fiber Blanket Market. These blankets are made from a blend of alumina and silica, providing a cost-effective solution for high-temperature insulation. They are widely used in applications where thermal insulation is required, but the purity of the material is not a critical factor. Conventional ceramic fiber blankets offer excellent thermal stability, low thermal conductivity, and resistance to thermal shock, making them suitable for use in kilns, furnaces, and other high-temperature environments. They are also lightweight and easy to handle, which simplifies installation and reduces labor costs. High Purity Ceramic Fiber Blankets, on the other hand, are designed for applications that require higher purity levels and enhanced performance. These blankets are made from high-purity alumina and silica, providing superior thermal insulation and chemical resistance. They are ideal for use in environments where contamination must be minimized, such as in the production of high-quality ceramics or in the aerospace industry. High purity ceramic fiber blankets offer improved thermal stability and can withstand higher temperatures compared to conventional blankets. This makes them suitable for use in more demanding applications where performance and reliability are critical. Other types of ceramic fiber blankets available in the market include zirconia ceramic fiber blankets and bio-soluble ceramic fiber blankets. Zirconia ceramic fiber blankets are designed for extreme temperature applications, offering exceptional thermal insulation and resistance to chemical attack. They are used in industries such as steel and petrochemicals, where high-temperature processes are common. Bio-soluble ceramic fiber blankets, on the other hand, are designed to address health and safety concerns associated with traditional ceramic fiber products. These blankets are made from materials that are less harmful to human health and the environment, making them a safer alternative for use in various industrial applications. Overall, the Global Industrial Ceramic Fiber Blanket Market offers a wide range of products to meet the diverse needs of different industries, each with its unique set of properties and benefits.

Steel Industry, Ceramic Industry, Electric Power, Petrochemical, Aerospace, Others in the Global Industrial Ceramic Fiber Blanket Market:

The Global Industrial Ceramic Fiber Blanket Market finds extensive usage across various industries due to its superior thermal insulation properties. In the steel industry, ceramic fiber blankets are used to line furnaces, ladles, and other high-temperature equipment. They help in maintaining the required temperature levels, reducing heat loss, and improving energy efficiency. This not only enhances the quality of the steel produced but also reduces operational costs by minimizing energy consumption. In the ceramic industry, these blankets are used in kilns and other high-temperature processing equipment to ensure uniform heat distribution and prevent thermal shock. This is crucial for maintaining the integrity and quality of ceramic products. The electric power industry also benefits from the use of ceramic fiber blankets, particularly in power plants where they are used to insulate boilers, turbines, and other high-temperature equipment. This helps in improving the efficiency of power generation and reducing greenhouse gas emissions. In the petrochemical industry, ceramic fiber blankets are used to insulate reactors, reformers, and other high-temperature processing units. They help in maintaining the required temperature levels, ensuring efficient chemical reactions, and reducing energy consumption. The aerospace industry also utilizes ceramic fiber blankets for their lightweight and high-temperature resistance properties. They are used in the manufacturing of aircraft components and in thermal protection systems for spacecraft. Other industries that benefit from the use of ceramic fiber blankets include glass manufacturing, aluminum production, and automotive manufacturing. In each of these industries, ceramic fiber blankets play a crucial role in improving energy efficiency, reducing operational costs, and enhancing the quality of the final product. Overall, the Global Industrial Ceramic Fiber Blanket Market is essential for various industries that require high-temperature insulation solutions to improve efficiency and sustainability.

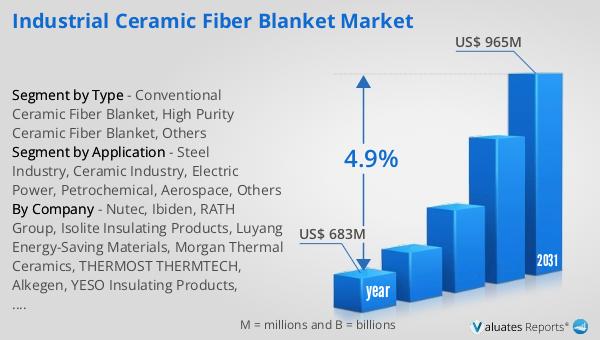

Global Industrial Ceramic Fiber Blanket Market Outlook:

The global market for Industrial Ceramic Fiber Blanket was valued at approximately $683 million in 2024. It is anticipated to grow significantly, reaching an estimated size of $965 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.9% during the forecast period. The increasing demand for energy-efficient solutions and the need to reduce energy consumption in industrial processes are key factors driving this growth. Industries such as steel, ceramics, petrochemicals, and power generation are increasingly adopting ceramic fiber blankets to enhance their operational efficiency and reduce greenhouse gas emissions. The market is also benefiting from the growing emphasis on sustainability and environmental regulations, which are encouraging industries to adopt more energy-efficient and environmentally friendly solutions. Additionally, the expanding industrialization in emerging economies is creating new growth opportunities for the market. As industries in these regions continue to develop, the demand for high-temperature insulation solutions like ceramic fiber blankets is expected to rise. Overall, the Global Industrial Ceramic Fiber Blanket Market is poised for significant growth in the coming years, driven by the increasing demand for energy-efficient solutions and the need to reduce energy consumption in industrial processes.

| Report Metric | Details |

| Report Name | Industrial Ceramic Fiber Blanket Market |

| Accounted market size in year | US$ 683 million |

| Forecasted market size in 2031 | US$ 965 million |

| CAGR | 4.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nutec, Ibiden, RATH Group, Isolite Insulating Products, Luyang Energy-Saving Materials, Morgan Thermal Ceramics, THERMOST THERMTECH, Alkegen, YESO Insulating Products, Nische Solutions, Mineral Seal Corporation, Annec Group, CeramSource, IKING GROUP, CCEWOOL, Andy Group, Vitcas, CeraMaterials, Zhengzhou Shengshi Jinding Insulation Refractory |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |