What is Global Industrial Ceramic Fiber Insulation Blanket Market?

The Global Industrial Ceramic Fiber Insulation Blanket Market is a specialized segment within the broader insulation industry, focusing on the production and distribution of ceramic fiber blankets. These blankets are made from alumina-silica materials and are known for their excellent thermal insulation properties, lightweight nature, and resistance to high temperatures. They are widely used in industries that require high-temperature insulation solutions, such as steel, ceramics, petrochemicals, and aerospace. The market is driven by the increasing demand for energy-efficient solutions and the need to reduce energy consumption in industrial processes. Additionally, the growing emphasis on sustainability and environmental regulations has led to the adoption of ceramic fiber insulation blankets as they help in reducing greenhouse gas emissions by improving energy efficiency. The market is characterized by the presence of several key players who are continuously investing in research and development to enhance the performance and durability of these insulation materials. As industries continue to seek advanced insulation solutions to meet their operational needs, the Global Industrial Ceramic Fiber Insulation Blanket Market is expected to witness significant growth in the coming years.

Conventional Ceramic Fiber Blanket, Biosoluble Ceramic Fiber Blanket in the Global Industrial Ceramic Fiber Insulation Blanket Market:

Conventional Ceramic Fiber Blankets and Biosoluble Ceramic Fiber Blankets are two primary types of products within the Global Industrial Ceramic Fiber Insulation Blanket Market. Conventional Ceramic Fiber Blankets are made from a combination of alumina and silica, providing excellent thermal insulation and resistance to high temperatures. These blankets are widely used in industries such as steel, ceramics, and petrochemicals, where high-temperature processes are common. They are known for their durability, lightweight nature, and ability to withstand thermal shock, making them ideal for applications that require reliable insulation under extreme conditions. However, conventional ceramic fiber blankets have faced scrutiny due to health concerns associated with the inhalation of fibers, leading to the development of alternative solutions. Biosoluble Ceramic Fiber Blankets, on the other hand, are designed to address the health and environmental concerns associated with conventional ceramic fibers. These blankets are made from a blend of calcium, magnesium, and silica, which makes them soluble in bodily fluids, reducing the potential health risks associated with fiber inhalation. Biosoluble ceramic fiber blankets offer similar thermal insulation properties as their conventional counterparts but with the added benefit of being more environmentally friendly and safer for workers handling the material. As industries become more conscious of health and safety regulations, the demand for biosoluble ceramic fiber blankets is expected to increase. The choice between conventional and biosoluble ceramic fiber blankets depends on various factors, including the specific application requirements, temperature range, and regulatory compliance. While conventional ceramic fiber blankets continue to be popular due to their proven performance and cost-effectiveness, biosoluble ceramic fiber blankets are gaining traction in markets where health and environmental considerations are paramount. Manufacturers in the Global Industrial Ceramic Fiber Insulation Blanket Market are focusing on expanding their product portfolios to include both types of blankets, catering to the diverse needs of their customers. In conclusion, both conventional and biosoluble ceramic fiber blankets play a crucial role in the Global Industrial Ceramic Fiber Insulation Blanket Market. While conventional blankets offer excellent thermal insulation and durability, biosoluble blankets provide a safer and more environmentally friendly alternative. As industries continue to evolve and prioritize health and safety, the demand for biosoluble ceramic fiber blankets is likely to grow, driving innovation and development within the market. Manufacturers are expected to invest in research and development to enhance the performance and safety of these insulation materials, ensuring they meet the ever-changing needs of industrial applications.

Steel Industry, Ceramic Industry, Electric Power, Petrochemical, Aerospace, Others in the Global Industrial Ceramic Fiber Insulation Blanket Market:

The Global Industrial Ceramic Fiber Insulation Blanket Market finds extensive usage across various industries due to its superior thermal insulation properties and ability to withstand high temperatures. In the steel industry, ceramic fiber insulation blankets are used in furnaces, ladles, and other high-temperature equipment to improve energy efficiency and reduce heat loss. The lightweight nature of these blankets makes them easy to install and replace, minimizing downtime and maintenance costs. By providing effective insulation, ceramic fiber blankets help steel manufacturers achieve consistent product quality and optimize their energy consumption. In the ceramic industry, ceramic fiber insulation blankets are used in kilns and other high-temperature processing equipment. These blankets help maintain uniform temperatures, ensuring the quality and consistency of ceramic products. The ability of ceramic fiber blankets to withstand thermal shock and resist chemical attacks makes them ideal for use in the harsh environments of ceramic manufacturing. Additionally, their lightweight nature and flexibility allow for easy installation and customization to fit various equipment configurations. The electric power industry also benefits from the use of ceramic fiber insulation blankets, particularly in power plants and other facilities where high-temperature processes are involved. These blankets help improve the efficiency of boilers, turbines, and other equipment by reducing heat loss and maintaining optimal operating temperatures. By enhancing energy efficiency, ceramic fiber blankets contribute to reducing greenhouse gas emissions and supporting sustainability initiatives within the power sector. In the petrochemical industry, ceramic fiber insulation blankets are used in reactors, reformers, and other high-temperature processing units. These blankets provide effective insulation, helping to maintain the desired temperature profiles and improve the efficiency of chemical reactions. The resistance of ceramic fiber blankets to chemical attacks and thermal shock makes them suitable for use in the demanding environments of petrochemical processing. By reducing heat loss and improving energy efficiency, ceramic fiber blankets help petrochemical companies optimize their operations and reduce operational costs. The aerospace industry also utilizes ceramic fiber insulation blankets in various applications, including aircraft engines and exhaust systems. The lightweight nature of these blankets makes them ideal for use in aerospace applications, where weight reduction is a critical consideration. Ceramic fiber blankets provide effective thermal insulation, helping to protect sensitive components from extreme temperatures and ensuring the safe and efficient operation of aerospace systems. In addition to these industries, ceramic fiber insulation blankets are used in various other applications, including automotive, glass manufacturing, and foundries. The versatility and performance of ceramic fiber blankets make them a preferred choice for industries seeking reliable and efficient insulation solutions. As industries continue to prioritize energy efficiency and sustainability, the demand for ceramic fiber insulation blankets is expected to grow, driving innovation and development within the Global Industrial Ceramic Fiber Insulation Blanket Market.

Global Industrial Ceramic Fiber Insulation Blanket Market Outlook:

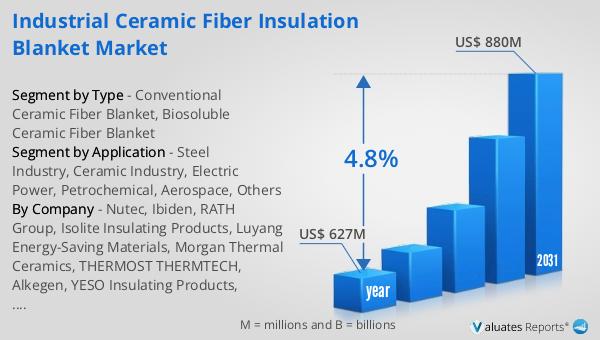

The global market for Industrial Ceramic Fiber Insulation Blanket was valued at $627 million in 2024 and is anticipated to expand to a revised size of $880 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.8% during the forecast period. This growth trajectory underscores the increasing demand for high-performance insulation solutions across various industries. The market's expansion is driven by the need for energy-efficient materials that can withstand extreme temperatures while reducing energy consumption and operational costs. As industries continue to seek advanced insulation solutions to meet their operational needs, the Global Industrial Ceramic Fiber Insulation Blanket Market is expected to witness significant growth in the coming years. The market is characterized by the presence of several key players who are continuously investing in research and development to enhance the performance and durability of these insulation materials. The growing emphasis on sustainability and environmental regulations has led to the adoption of ceramic fiber insulation blankets as they help in reducing greenhouse gas emissions by improving energy efficiency. As industries continue to evolve and prioritize health and safety, the demand for biosoluble ceramic fiber blankets is likely to grow, driving innovation and development within the market.

| Report Metric | Details |

| Report Name | Industrial Ceramic Fiber Insulation Blanket Market |

| Accounted market size in year | US$ 627 million |

| Forecasted market size in 2031 | US$ 880 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nutec, Ibiden, RATH Group, Isolite Insulating Products, Luyang Energy-Saving Materials, Morgan Thermal Ceramics, THERMOST THERMTECH, Alkegen, YESO Insulating Products, Nische Solutions, Mineral Seal Corporation, Annec Group, CeramSource, IKING GROUP, CCEWOOL, Andy Group, Vitcas, CeraMaterials, Zhengzhou Shengshi Jinding Insulation Refractory |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |