What is Global Ultrasonic Strip and Plate Inspection System Market?

The Global Ultrasonic Strip and Plate Inspection System Market is a specialized segment within the broader non-destructive testing (NDT) industry. This market focuses on the use of ultrasonic technology to inspect strips and plates, which are essential components in various industrial applications. Ultrasonic inspection systems utilize high-frequency sound waves to detect internal flaws, measure thickness, and evaluate material properties without causing any damage to the components being tested. These systems are crucial for ensuring the quality and safety of materials used in industries such as automotive, aerospace, construction, and energy. The demand for ultrasonic inspection systems is driven by the need for high precision and reliability in quality control processes. As industries continue to prioritize safety and efficiency, the adoption of advanced inspection technologies like ultrasonic systems is expected to grow. The market is characterized by continuous technological advancements, with manufacturers focusing on developing more sophisticated and user-friendly systems to meet the evolving needs of their customers. Overall, the Global Ultrasonic Strip and Plate Inspection System Market plays a vital role in enhancing the quality assurance processes across various sectors, contributing to improved product performance and safety standards.

in the Global Ultrasonic Strip and Plate Inspection System Market:

The Global Ultrasonic Strip and Plate Inspection System Market offers a variety of types that cater to the diverse needs of its customers. These types are primarily distinguished by their specific applications, technological features, and the industries they serve. One of the most common types is the portable ultrasonic inspection system, which is highly favored for its mobility and ease of use. These systems are ideal for on-site inspections, allowing technicians to perform quick and accurate assessments of materials in various locations. Portable systems are particularly useful in industries such as construction and maintenance, where flexibility and rapid deployment are crucial. Another type is the automated ultrasonic inspection system, which is designed for high-volume and high-speed inspection processes. These systems are typically integrated into production lines, providing continuous monitoring and quality control. Automated systems are widely used in industries like automotive and aerospace, where precision and efficiency are paramount. They offer the advantage of reducing human error and increasing inspection throughput. Additionally, there are specialized ultrasonic inspection systems tailored for specific applications, such as thickness gauging and flaw detection. Thickness gauging systems are used to measure the thickness of materials, ensuring they meet the required specifications. Flaw detection systems, on the other hand, are designed to identify internal defects such as cracks, voids, and inclusions. These systems are essential in industries where material integrity is critical, such as oil and gas, and power generation. Furthermore, the market also includes advanced ultrasonic inspection systems equipped with phased array technology. Phased array systems offer enhanced imaging capabilities, allowing for more detailed and accurate inspections. They are particularly beneficial in complex applications where traditional ultrasonic methods may fall short. The versatility and adaptability of phased array systems make them suitable for a wide range of industries, including shipbuilding and railways. In addition to these types, the market also sees the use of immersion ultrasonic inspection systems, which involve submerging the test material in a liquid medium to improve sound wave transmission. Immersion systems are often used in laboratory settings for detailed analysis and research purposes. Overall, the Global Ultrasonic Strip and Plate Inspection System Market provides a comprehensive range of options to meet the diverse inspection needs of its customers, ensuring high-quality and reliable outcomes across various industries.

Industrial Manufacturing, Railway Transportation, Others in the Global Ultrasonic Strip and Plate Inspection System Market:

The usage of Global Ultrasonic Strip and Plate Inspection System Market spans several key areas, including industrial manufacturing, railway transportation, and others. In industrial manufacturing, ultrasonic inspection systems are integral to quality control processes. They are used to inspect raw materials, semi-finished products, and finished goods to ensure they meet the required standards and specifications. By detecting internal flaws and measuring material thickness, these systems help manufacturers maintain product quality and prevent defects that could lead to costly recalls or failures. Industries such as automotive, aerospace, and electronics heavily rely on ultrasonic inspection systems to ensure the safety and reliability of their products. In railway transportation, ultrasonic inspection systems play a crucial role in maintaining the safety and integrity of railway tracks and components. These systems are used to inspect rails, wheels, and other critical components for defects that could compromise the safety of train operations. By identifying potential issues early, railway operators can perform timely maintenance and repairs, reducing the risk of accidents and ensuring smooth and efficient train services. Ultrasonic inspection systems are also used in the manufacturing of railway components, ensuring they meet the stringent safety standards required for railway applications. Beyond industrial manufacturing and railway transportation, ultrasonic inspection systems find applications in various other sectors. In the oil and gas industry, they are used to inspect pipelines, storage tanks, and other infrastructure for corrosion and defects. This helps prevent leaks and spills, ensuring the safe and efficient operation of oil and gas facilities. In the power generation sector, ultrasonic inspection systems are used to inspect turbines, boilers, and other critical components to ensure their reliability and performance. Additionally, these systems are used in the construction industry to inspect structural components and ensure the safety and integrity of buildings and infrastructure. Overall, the Global Ultrasonic Strip and Plate Inspection System Market provides essential tools for ensuring safety, quality, and efficiency across a wide range of industries, contributing to improved operational performance and reduced risks.

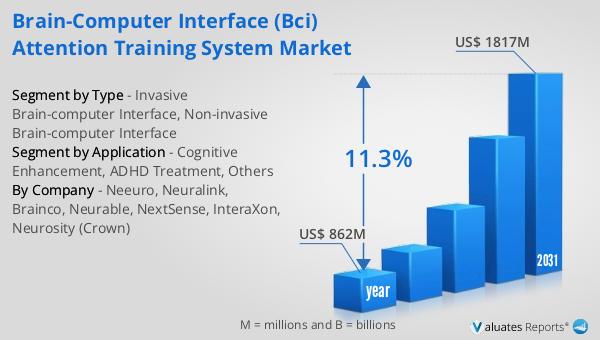

Global Ultrasonic Strip and Plate Inspection System Market Outlook:

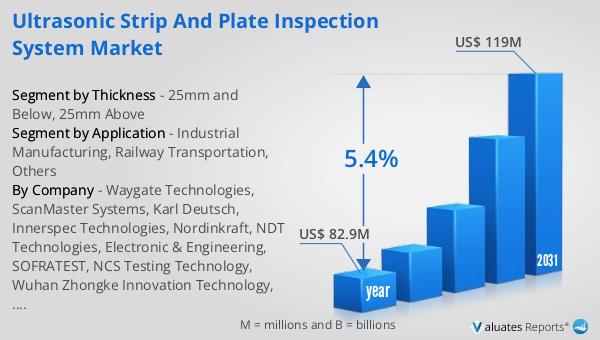

The global market for Ultrasonic Strip and Plate Inspection System was valued at $82.9 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is expected to reach a revised size of $119 million, reflecting a compound annual growth rate (CAGR) of 5.4% during the forecast period. This growth is indicative of the increasing demand for advanced inspection technologies across various industries. As companies continue to prioritize quality assurance and safety, the adoption of ultrasonic inspection systems is likely to rise. These systems offer a non-destructive method of evaluating materials, which is crucial for maintaining the integrity and reliability of products and infrastructure. The projected growth in the market underscores the importance of ultrasonic inspection systems in modern industrial processes. With continuous advancements in technology, these systems are becoming more sophisticated, offering enhanced capabilities and improved user experience. As a result, they are becoming an integral part of quality control and maintenance strategies in industries such as automotive, aerospace, construction, and energy. The market's expansion also highlights the growing awareness of the benefits of ultrasonic inspection systems, including their ability to detect internal flaws, measure material thickness, and ensure compliance with industry standards. Overall, the Global Ultrasonic Strip and Plate Inspection System Market is poised for significant growth, driven by the increasing need for reliable and efficient inspection solutions across various sectors.

| Report Metric | Details |

| Report Name | Ultrasonic Strip and Plate Inspection System Market |

| Accounted market size in year | US$ 82.9 million |

| Forecasted market size in 2031 | US$ 119 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Thickness |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Waygate Technologies, ScanMaster Systems, Karl Deutsch, Innerspec Technologies, Nordinkraft, NDT Technologies, Electronic & Engineering, SOFRATEST, NCS Testing Technology, Wuhan Zhongke Innovation Technology, Nantong Union Digital Technology Development |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |